A Rolling and Sliding Mixed Friction Stepless Speed Adjuster

A technology of stepless speed control box and mixed friction, which is applied in the direction of transmission, transmission control, and components with teeth, etc. It can solve the problems of reduced magnetic field strength of permanent magnets, temperature sensitivity of permanent magnets, and restricted speed regulation performance. Achieve good braking effect, increase friction area, and superior explosion-proof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

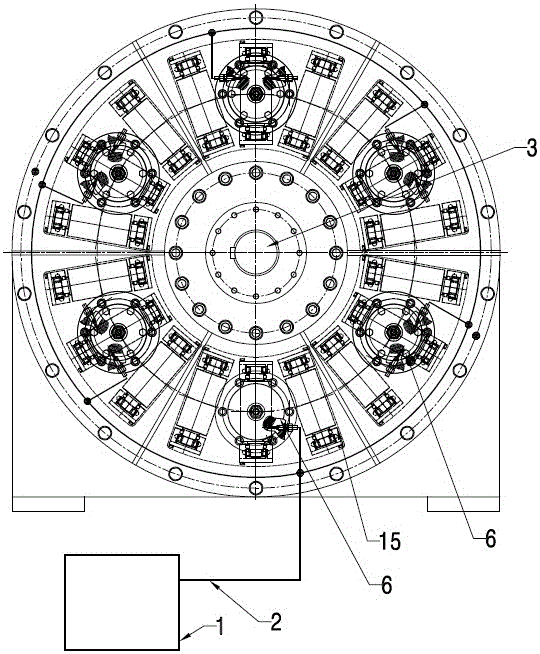

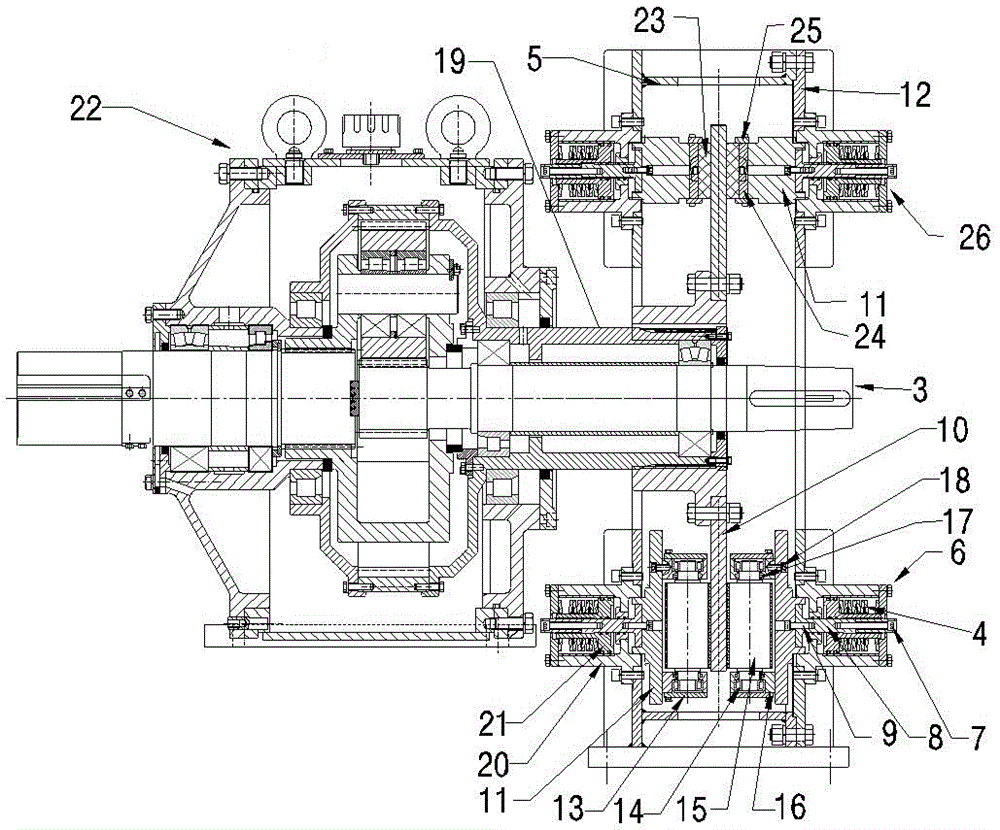

[0035] Such as Figure 1~2 As shown, a rolling and sliding mixed friction stepless speed regulating box includes a planetary differential reducer 22, a flywheel 10 installed on the exposed rotating shaft 19 of the planetary differential reducer, and a flywheel symmetrically installed 10. Six pairs of disc brakes on both sides to adjust the speed of the flywheel;

[0036] Described disc brake comprises rolling disc brake 6 and sliding disc brake 26, and rolling disc brake 6 comprises piston cylinder 20, piston rod 8, and the piston 21 that piston rod 8 rear end is fixedly connected, and piston 21 is positioned at piston cylinder 20. Disc spring 4 is installed inside and on its outer wall, and one end of disc spring 4 is fixedly connected with the cylinder head of the piston cylinder, and the piston 21 is pushed to move through the pre-compressed disc spring 4, thereby pushing the piston rod 8 to move axially.

[0037]The front end of the piston rod 8 of the rolling disc gate 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com