Preparation method of cannabis sativa protein ACE (Angiotensin Converting Enzyme) peptide inhibitor

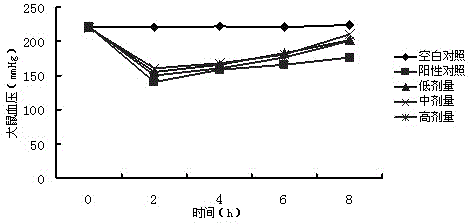

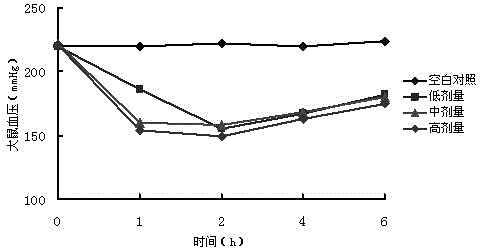

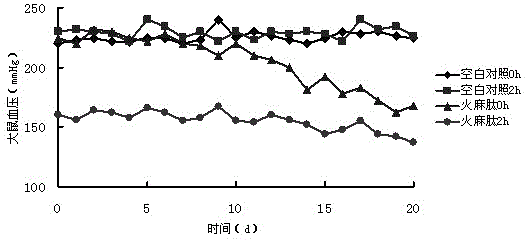

A technology of hemp protein and inhibitory peptides, which is applied in the field of preparation of hemp protein ACE inhibitory peptides, can solve problems such as limitations and waste of resources, and achieve the effects of lowering blood pressure, improving utilization levels, and being easy to digest

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 1. Extraction of hemp seed protein: extraction of hemp seed protein: take defatted hemp seed meal, dry, pulverize, and sieve to remove impurities. Add water until the ratio of material to liquid is 1:12g / mL, homogenate with a colloid mill, the temperature of the homogenate is 25°C, the gap between the colloid mill is 0.1mm, the homogenization time is 5min, the material after homogenization is passed through a 600 mesh sieve, and the The pH value was 8.5, and ultrasonic-assisted extraction was carried out at a temperature of 25°C, a power of 120W, and a duty ratio of 20:20s / s. Under the condition of a water bath temperature of 50°C, the protein was extracted for 60 minutes at a constant temperature, and then 1 mol / L of The HCl solution was adjusted to the isoelectric point of the hemp seed protein. After fully stirring, the protein was still precipitated to allow the protein to fully sink, and the supernatant was removed by centrifugation at 5000 r / min for 20 min; Add wa...

Embodiment 2

[0034]1. Extraction of hemp seed protein: take defatted hemp seed meal by weighing, dry, pulverize, and sieve to remove impurities. Add water until the material-to-liquid ratio is 1:20 g / mL, homogenate with a colloid mill, the homogenate temperature is 25°C, the gap between the colloid mill is 1mm, the homogenate time is 8min, and the material after homogenization is passed through a 600-mesh sieve. Adjust the pH value to 8, and carry out ultrasonic-assisted extraction at a temperature of 30°C, a power of 150W, and a duty ratio of 20:20s / s. Under the condition of a water bath temperature of 55°C, the protein was extracted by constant temperature alkali for 80 minutes, and then 1 mol / L The HCl solution was adjusted to the isoelectric point of the hemp seed protein, and after fully stirring, the static precipitation was allowed to fully sink the protein, and the supernatant was removed by centrifugation at 6000 r / min for 15 min; the precipitation was carried out for the second al...

Embodiment 3

[0040] 1. Extraction of hemp seed protein: take defatted hemp seed meal by weighing, dry, pulverize, and sieve to remove impurities. Add water until the ratio of material to liquid is 1:15 g / mL, homogenize with a colloid mill, the homogenization temperature is 30°C, the gap between the colloid mill is 0.5mm, the homogenization time is 10min, and the homogenized material is passed through a 600-mesh sieve , adjusted the pH value to 8, and carried out ultrasonic-assisted extraction at a temperature of 20°C, a power of 200W, and a duty ratio of 20:20s / s. Under the condition of a water bath temperature of 45°C, the protein was extracted by constant temperature alkali for 40 minutes, and then 1 mol / The HCl solution in 1 L was adjusted to the isoelectric point of the hemp seed protein. After fully stirring, the precipitation was static to allow the protein to fully sink, and the supernatant was removed by centrifugation at 6000 r / min for 15 minutes; the precipitation was carried ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com