Mine use hole packer hole packing material

A technology of sealing material and sealing device, which is applied in the direction of sealing/sealing, drilling composition, chemical instruments and methods, etc., which can solve the problems of fast reaction speed, undense sealing, violent reaction, etc., and achieve rapid The effect of expansion and solidification, reducing labor intensity and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] A hole sealing material for a mining hole sealer, which is composed of the following parts by weight: calcium hydroxide 0.5-0.8, sodium chloride 0.5-1.5, sodium thiosulfate 1.0-2.5, pulling powder BX 0.1-0.4, calcium silicate 1~5, water reducer JN 0.2~0.4, ammonium chloride 0.3~0.7, aluminum hydroxide 0.001~0.006, calcium chlorate 0.001~0.006, iron powder 80~90, calcium carbonate 1.2~1.5, magnesium hydroxide 0.05~0.20.

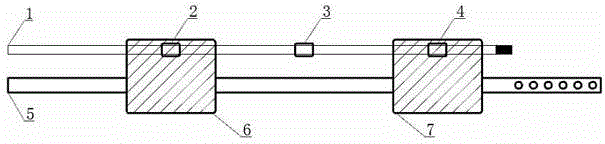

[0017] Further, the method for using the hole sealing material of the mining hole sealing device for hole sealing is as follows: 1. Install the hole sealing device: clean the borehole, and cover the bag with the end of the pressure head on the first hole of the required sealing length. On one suction pipe, the grouting pipe is fixed on the suction pipe with scotch tape, and the 1cm at both ends of the pouch is first fixed with cable ties, then tightened with thin wire, and covered with scotch tape successively; Put the pouch at the other end on the las...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com