Preparation method of 4,4'-dihydroxy-3,3'-diamino diphenyl ketone

A technology of diaminobenzophenone and dinitrobenzophenone, which is applied in the field of preparation of 4,4'-dihydroxy-3,3'-diaminobenzophenone, can solve the problem that does not have industrial production value, raw materials are not easy to obtain, and the process is complicated, so as to achieve the effect of high purity and yield, low production cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

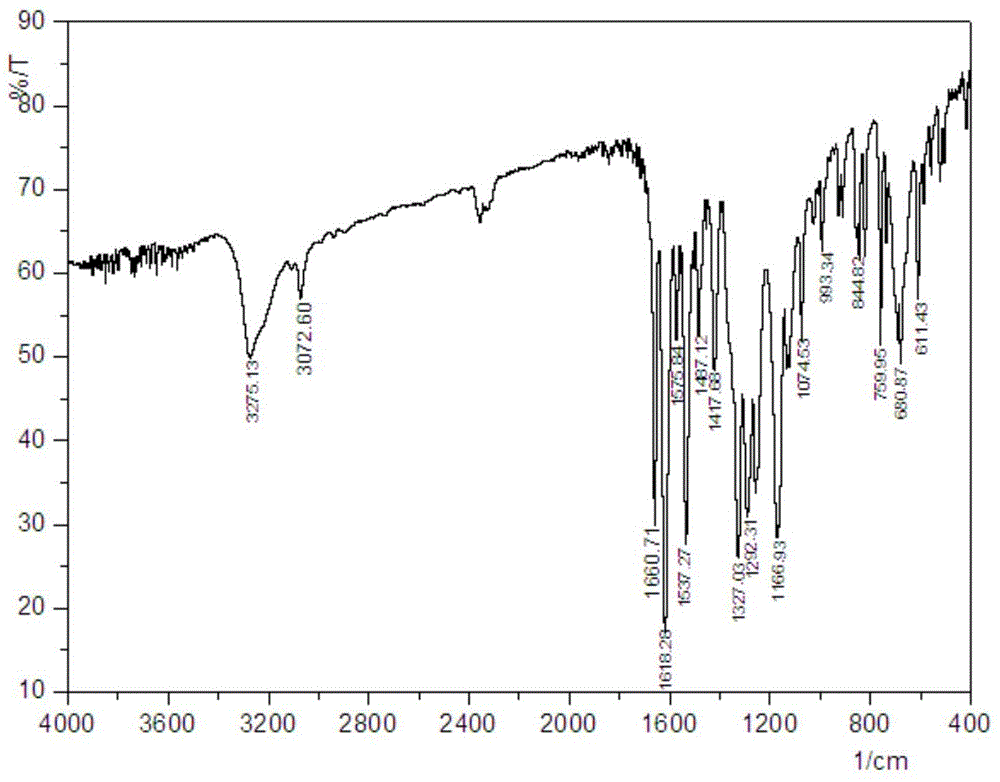

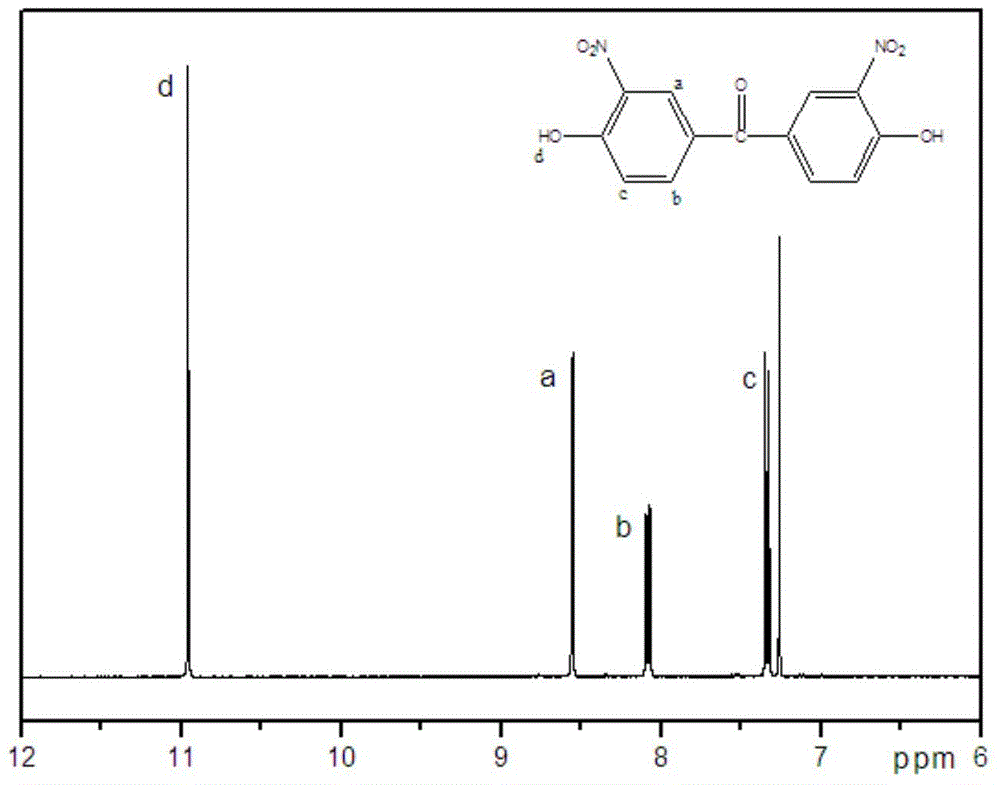

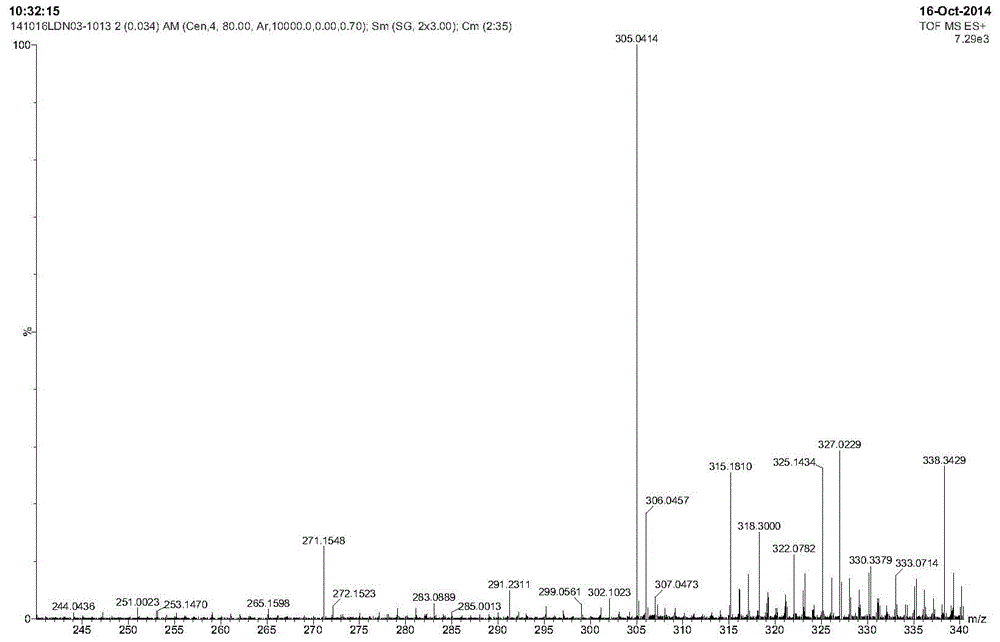

[0050] Add a mass concentration of 60% ethanol aqueous solution and 2.2g (0.055mol) NaOH solid to a four-neck flask equipped with a condenser tube, a thermometer and a stirring paddle and mix evenly. After the mixed solution is heated to 60°C, add Add 3.41g (0.01mol) 4,4'-dichloro-3,3'-dinitrobenzophenone, and maintain the temperature at 60°C for 24 hours to obtain an orange-red slurry, add 100ml Water completely dissolves the slurry to form an orange-red transparent solution, then adjusts the pH of the system to 1-2 with acid to completely change the sodium phenate into hydroxyl, filters and washes the product to be neutral, and then places it in an oven at a temperature of 80°C to dry it to obtain Orange-yellow powdery solid, the yield of the crude product obtained after weighing and calculation is 93.42%, and the purity is 88.10%. The product can be purified by recrystallizing the hydrolyzate with DMF and isopropanol. The product obtained after recrystallization is determin...

Embodiment 2

[0052] Add a mass concentration of 80% ethanol aqueous solution and 2.2g (0.055mol) NaOH solid to a four-neck flask equipped with a condenser tube, a thermometer and a stirring paddle and mix evenly. After the mixed solution is heated to 75°C, add Add 3.41g (0.01mol) of 4,4'-dichloro-3,3'-dinitrobenzophenone, and maintain the temperature at 75°C for 24 hours to obtain an orange-red slurry, add 100ml to the system Water completely dissolves the slurry to form an orange-red transparent solution, then adjusts the pH of the system to 1-2 with acid to completely change the sodium phenate into hydroxyl, filters and washes the product to be neutral, and then places it in an oven at a temperature of 80°C to dry it to obtain Orange powdery solid, the yield of the crude product obtained after weighing and calculation is 96.05%, and the purity is 89.92%.

Embodiment 3

[0054] Add a mass concentration of 50% ethanol aqueous solution and 3.2g (0.08mol) NaOH solid to a four-neck flask equipped with a condenser tube, a thermometer and a stirring paddle and mix evenly. After the mixed solution is heated to 100°C, add Add 3.41g (0.01mol) 4,4'-dichloro-3,3'-dinitrobenzophenone, and maintain the temperature at 100°C for 24 hours to obtain an orange-red slurry, add 100ml Water completely dissolves the slurry to form an orange-red transparent solution, then adjusts the pH of the system to 1-2 with acid to completely change the sodium phenate into hydroxyl, filters and washes the product to be neutral, and then places it in an oven at a temperature of 80°C to dry it to obtain Orange solid particles, the yield of the crude product is 95.34%, and the purity is 90.32%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com