Method for recycling crude product triethylamine in AKD (alkyl ketene dimer) production

A technology of triethylamine and crude products, which is applied in the field of solvent recycling treatment, can solve the problems that the recovery rate affects product cost and market competitiveness, the high price of triethylamine solvent, and the high investment cost of membrane separation, so as to achieve high production efficiency, High recovery rate and reduced steam consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

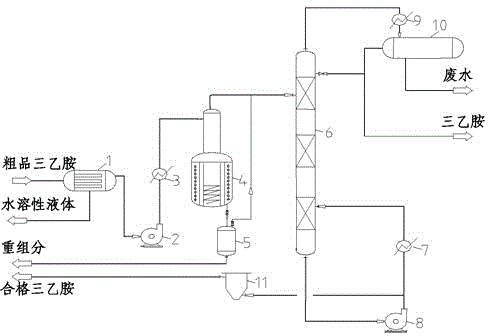

[0030] The first step: the mixture of the crude product triethylamine of 550kg / h generated and the brine of 1210kg / h is pressurized by a pump and then introduced into the fiber coalescer (1), and the pressure difference between the front and back ports of the fiber coalescer equipment is 0.30MPa, The light phase liquid can obtain 585.1kg / h (heavy component mass content 3.5%, water mass content 2.4%) crude triethylamine. Send to evaporator (4) with delivery pump (2) metering;

[0031] Second step: the crude product triethylamine enters from the top of the evaporator (4), and the temperature of the evaporator (4) is 120°C. Include the following steps:

[0032] (I) The preheater pressure is 0.50MPa;

[0033] (II) The outlet flow rate at the bottom of the evaporator (4) is 40.6kg / h;

[0034] (Ⅲ) The outlet flow rate at the bottom of the reevaporator (5) is 20.2kg / h;

[0035](IV) The gas phase outlet pressure of the evaporator (4) and re-evaporator (5) is 0.04 MPa.

[0036] Th...

Embodiment 2

[0043] The first step: the mixture of the crude product triethylamine of 1700kg / h generated and the brine of 2215kg / h is pressurized by a pump and introduced into the fiber coalescer (1), and the pressure difference between the front and rear ports of the fiber coalescer equipment is 0.50MPa, The light phase liquid can obtain 1813.3kg / h (heavy component mass content 4.1%, water mass content 1.9%) crude triethylamine. Send to evaporator (4) with delivery pump (2) metering;

[0044] Second step: the crude product triethylamine enters from the top of the evaporator (4), and the temperature of the evaporator (4) is 120°C. Include the following steps:

[0045] (I) The preheater pressure is 0.70MPa;

[0046] (II) The outlet flow rate at the bottom of the evaporator (4) is 83.5kg / h;

[0047] (Ⅲ) The outlet flow rate at the bottom of the reevaporator (5) is 79.3kg / h;

[0048] (IV) The gas phase outlet pressure of the evaporator (4) and re-evaporator (5) is 0.03 MPa.

[0049] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com