Nanofiber foam based device for continuous treatment of dye wastewater and preparation method of device

A nanofiber, dye wastewater technology, applied in the textile industry wastewater treatment, water/sewage treatment equipment, water/sewage treatment and other directions, can solve the difficulty in meeting the application requirements of dye wastewater treatment, the complex dye wastewater treatment process, and the inability to achieve continuous operation and other problems, to achieve the effect of continuous high-efficiency dye adsorption and separation, fast and high-efficiency adsorption and separation, and ensure high-efficiency and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

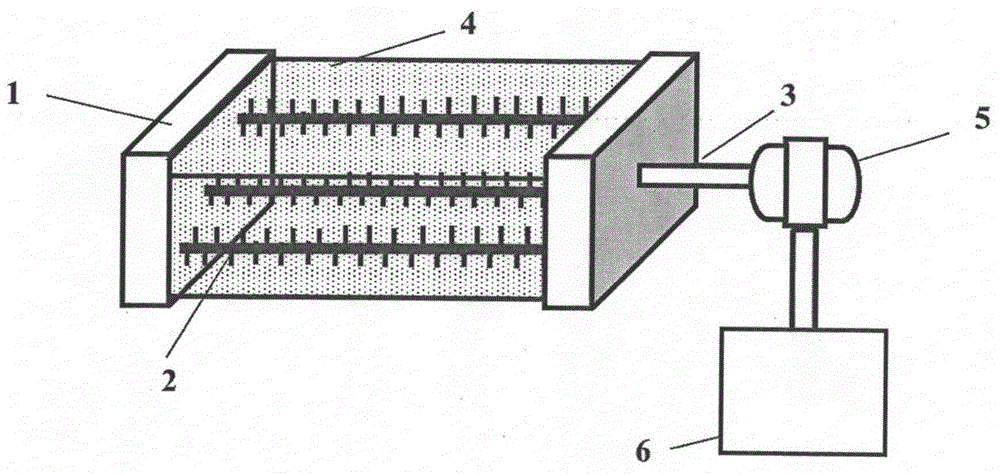

[0028] Such as figure 1 As shown, it is a schematic structural diagram of a nanofiber foam-based continuous dye wastewater treatment device. The nanofiber foam-based continuous dye wastewater treatment device includes a nanofiber bubble dye wastewater treatment module, and the nanofiber bubble dye wastewater treatment module includes protection. Net cover 1, the super-hydrophilic nanofiber foam 4 located in the protective net cover 1, and the water-collecting capillary network 2 distributed in the super-hydrophilic nano-fiber foam 4, the water-collecting capillary network of the nanofiber foam dye wastewater treatment module 2 is connected to the main water delivery pipe 3, the main water delivery pipe 3 is connected to the water pump 5, and the water pump 5 is connected to the water storage tank 6. The main water delivery pipe is provided with multiple expansion interfaces for connecting with multiple sets of nanofiber bubble dye wastewater treatment modules.

[0029] The pr...

Embodiment 2

[0036] Such as figure 1 As shown, it is a schematic structural diagram of a nanofiber foam-based continuous dye wastewater treatment device. The nanofiber foam-based continuous dye wastewater treatment device includes a nanofiber bubble dye wastewater treatment module, and the nanofiber bubble dye wastewater treatment module includes protection. Net cover 1, the super-hydrophilic nanofiber foam 4 located in the protective net cover 1, and the water-collecting capillary network 2 distributed in the super-hydrophilic nano-fiber foam 4, the water-collecting capillary network of the nanofiber foam dye wastewater treatment module 2 is connected to the main water delivery pipe 3, the main water delivery pipe 3 is connected to the water pump 5, and the water pump 5 is connected to the water storage tank 6. The main water delivery pipe is provided with multiple expansion interfaces for connecting with multiple sets of nanofiber bubble dye wastewater treatment modules.

[0037] The pr...

Embodiment 3

[0044] Such as figure 1 As shown, it is a schematic structural diagram of a nanofiber foam-based continuous dye wastewater treatment device. The nanofiber foam-based continuous dye wastewater treatment device includes a nanofiber bubble dye wastewater treatment module, and the nanofiber bubble dye wastewater treatment module includes protection. Net cover 1, the super-hydrophilic nanofiber foam 4 located in the protective net cover 1, and the water-collecting capillary network 2 distributed in the super-hydrophilic nano-fiber foam 4, the water-collecting capillary network of the nanofiber foam dye wastewater treatment module 2 is connected to the main water delivery pipe 3, the main water delivery pipe 3 is connected to the water pump 5, and the water pump 5 is connected to the water storage tank 6. The main water delivery pipe is provided with multiple expansion interfaces for connecting with multiple sets of nanofiber bubble dye wastewater treatment modules.

[0045] The pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com