Prefabricated part sweeping and oil spraying machine

A technology of prefabricated components and fuel injection machines, which is applied in the direction of spraying devices, spraying devices, manufacturing tools, etc. It can solve the problems of consuming a lot of time, manpower and material resources, the cleaning device is insufficient, and the oil film spraying is uneven, so as to achieve simple maintenance and easy work , low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

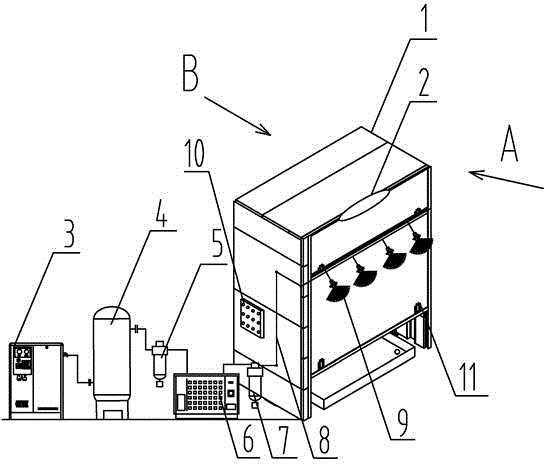

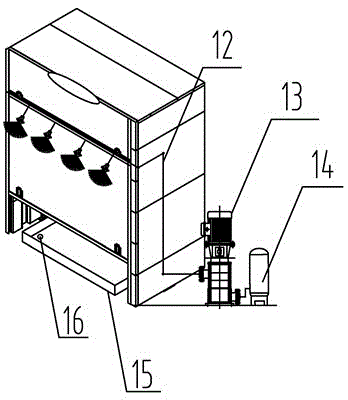

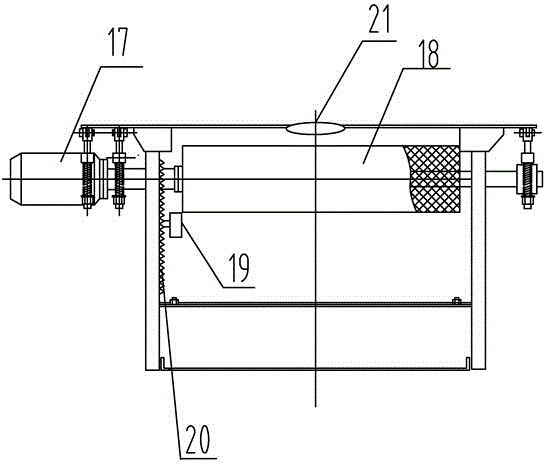

[0012] Referring to the accompanying drawings, a prefabricated component cleaning fuel injection machine includes a door frame 1, a tray inlet sensor 2, an air compressor 3, an air storage tank 4, a primary filter 5, a cold dryer 6, a medium filter 7, Compressed air pipeline 8, two-phase flow spray assembly 9, operation table 10, tray support wheel 11, oil pipeline 12, oil pump 13, oil storage tank 14, oil leakage residue tray 15, oil outlet hole 16, cleaning device motor 17. Steel cylinder cleaner 18, side mold cleaner 19, lifting device 20, tray outlet sensor 21, facing the left side of the spray master 9, an air pressure system for supplying compressed air to the equipment is arranged, and the air pressure is respectively arranged in sequence Machine 3, air storage tank 4, primary filter 5, cold dryer 6 and intermediate filter 7 are connected by compressed air pipeline 8, and console 10 is arranged on the left side wall of door frame 1, facing The oil supply system for supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com