Super-hydrophobic functional material, preparation method and application of the same

A functional material and super-hydrophobic technology, which is applied in the direction of surface coating liquid devices, pre-treated surfaces, coatings, etc., can solve problems such as poor weather resistance and loss of function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

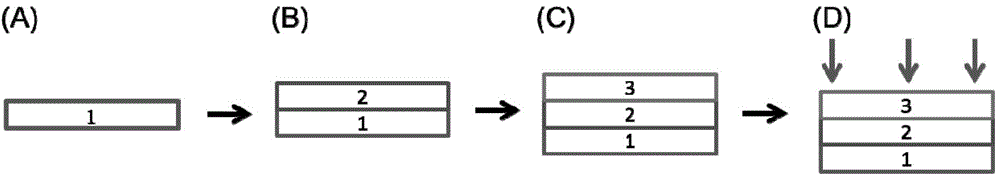

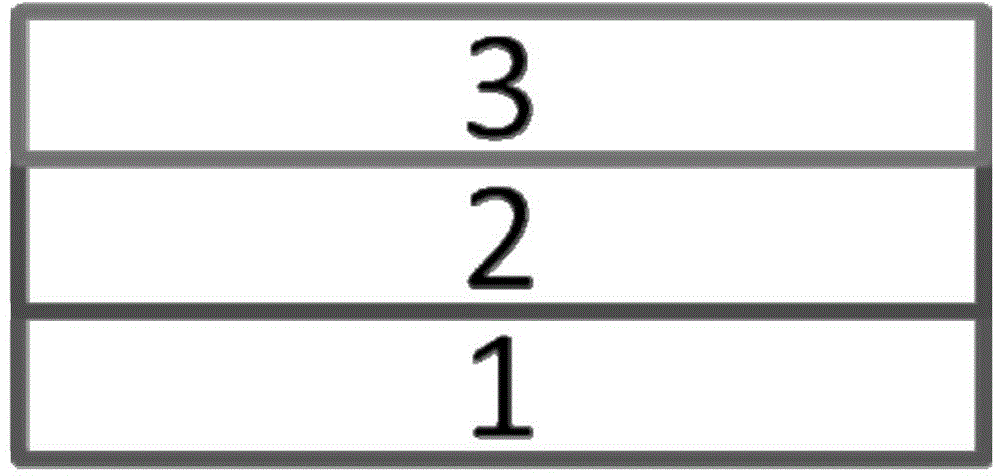

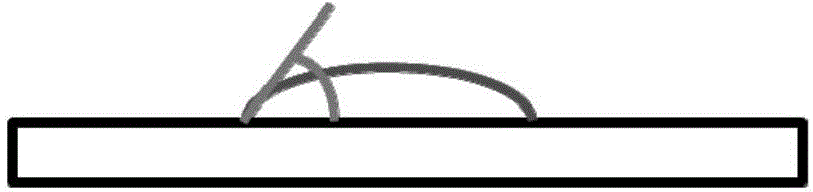

[0044] The present invention proposes a preparation method of superhydrophobic functional material, comprising:

[0045] Step 1: Select the material that needs super-hydrophobic treatment as the substrate layer, and clean the surface of the substrate layer until it is clean;

[0046] Step 2: Apply silicone oil, referred to as PDMS layer, on the substrate material and allow it to cure;

[0047] Step 3: Configure different concentrations of nanoparticle suspensions as required, apply nanoparticle suspensions on the silicone oil layer, and form nanoparticle film layers of different thicknesses on the silicone oil layer after the solvent for dispersing the nanoparticles evaporates;

[0048] Step 4: The nanoparticle film layer is subjected to ultraviolet light treatment or heat treatment to obtain a layered superhydrophobic functional material.

[0049] Wherein, the substrate is selected from materials bonded with silicone oil.

[0050] Wherein, the substrate is selected from hard ...

specific Embodiment 1

[0077] First, clean the copper sheet. Use a mixture of ethanol, acetone and deionized water to sonicate for 10 minutes; then use deionized water to sonicate for 10 minutes. Remove the copper piece and dry it with nitrogen gas.

[0078] The volume ratio of PDMS to curing agent is 10:1, mixed thoroughly and evenly, then spin-coated on copper, and then heated to make PDMS quickly and fully cured.

[0079] Put 10g of titanium dioxide particles with a particle size of 20nm in 80mL of absolute ethanol to form a turbid solution, mix with stirring for about 1min, and then sonicate for 10min to disperse the particles evenly.

[0080] Take a small amount of titanium dioxide-ethanol turbid liquid droplets on the PDMS / substrate, roll the droplets with a glass rod to make them evenly distributed on the PDMS surface, and leave a solid particle titanium dioxide film layer after the ethanol evaporates. The whole system has a three-layer structure. "TiO 2 / PDMS / copper” structure.

[0081] ...

specific Embodiment 2

[0082] First, the silicon wafer substrate that needs to be prepared as super-hydrophobic is cleaned, and the cleaning method is the same as that of the first embodiment above.

[0083] Other steps are also the same as in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com