Ore-dressing process for extracting copper and silver

A technology, copper and silver technology, applied in the field of extraction of copper and silver by ore dressing, can solve the problems that affect the efficiency of enterprises, waste of resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

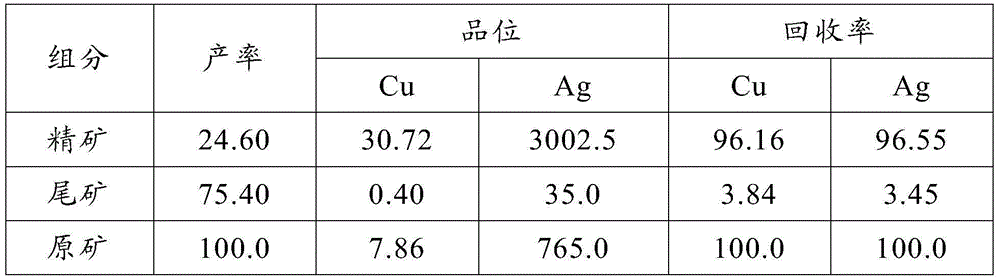

[0035] Grind the raw ore of the 3# inclined shaft of Baifang Copper Mine in Shuikou Mountain, and obtain 10t of beneficiation pulp after classification. The particle size of the beneficiation pulp is -106μm is 1.2t, and the particle size of -74μm is 1.08t. The concentration of slag in the 10t beneficiation pulp is 12wt %, the composition of the above raw ore is shown in Table 1; from the chemical multi-element analysis results of the raw ore in Table 1, it can be seen that copper and silver are valuable for recovery, and the oxidation rate of copper is 53.18%.

[0036] Add 1200g / t sodium sulfide, 400g / t isobutyl xanthate, 80g / t butyl xanthate and 200g / t terpineol oil to the pulp for roughing for 6 minutes to obtain 0.20t of coarse concentrate and 1.00t of coarse slag ; Concentrate the rough concentrate to obtain 0.108t concentrate and 0.092t middle ore 1; add 600g / t sodium sulfide, 200g / t isobutyl xanthate, 50g / t butylamine xanthate to the coarse slag Sweeping with 100g / t terp...

Embodiment 2

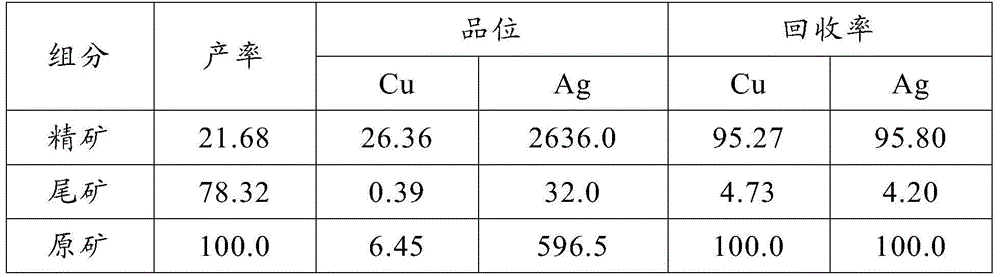

[0044] The 1# vertical shaft raw ore of Shuikoushan Baifang Copper Mine was ground, and after classification, 10t of pulp was obtained. The particle size in the pulp was -106μm1.4t, and the particle size was -74μm1.26t. The concentration of slag in the pulp was 14wt%;

[0045] Add 1500g / t sodium sulfide, 250g / t isobutyl xanthate, 90g / t butyl xanthate and 220g / t terpineol oil to the pulp for roughing for 6 minutes to obtain 0.32t rough concentrate and 1.08t rough slag ; Concentrate the rough concentrate to obtain 0.29t concentrate and 0.03t middle ore 1; add 600g / t sodium sulfide, 200g / t isobutyl xanthate, 60g / t butylamine xanthate to the coarse slag Sweeping with 100g / t terpineol oil for 8 minutes to obtain 0.14t of Zhongguo 2 and 0.94t of coarse slag; add 300g / t of sodium sulfide, 120g / t of isobutyl xanthate, and 30g / t of butylamine yellow to the above coarse slag Medicine and 80g / t pine alcohol oil were swept for 8 minutes to obtain 0.04t middling 3 and 0.90t tailings. Get ...

Embodiment 3

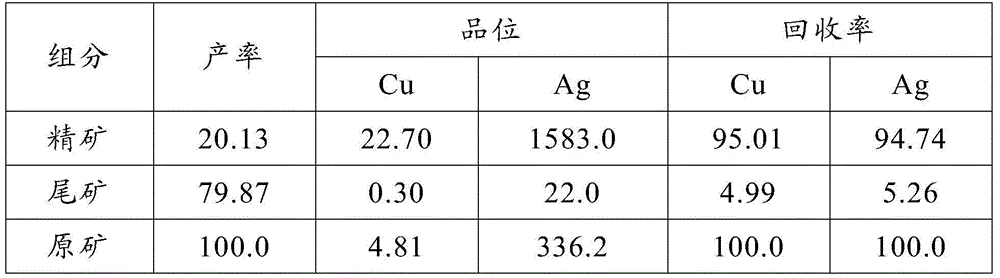

[0050] In a raw ore in Yunnan, the mudification rate is 55-70% (particle size -3mm), and the oxidation rate of copper in the raw ore is 75-85%. The above-mentioned raw ore is ground and graded to obtain 10t of ore pulp, and the particle size of the pulp is -106μm. 1.4t , wherein 1.26t with a particle size of -74 μm, the concentration of slag in the selected ore pulp is 14wt%;

[0051] Add 1200g / t sodium sulfide, 300g / t isobutyl xanthate, 80g / t butyl xanthate and 200g / t terpineol oil to the pulp for roughing for 6 minutes to obtain 0.35t of coarse concentrate and 1.05t of coarse slag ; Concentrate the rough concentrate to obtain 0.28t concentrate and 0.07t middle ore 1; add 600g / t sodium sulfide, 200g / t isobutyl xanthate, 40g / t butylamine xanthate to the coarse slag Sweeping with 100g / t terpineol oil for 8 minutes to obtain 0.12t of Zhongguo 2 and 0.93t of coarse slag; add 300g / t of sodium sulfide, 100g / t of isobutyl xanthate, and 30g / t of butylamine yellow to the above coarse ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com