Electrolyte of lithium ion battery taking lithium titanate as cathode

A technology of lithium-ion batteries and electrolytes, applied in electrolytes, secondary batteries, circuits, etc., can solve problems such as increased water content in batteries, achieve the effects of avoiding catalytic reactions, improving high-temperature storage and high-temperature cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

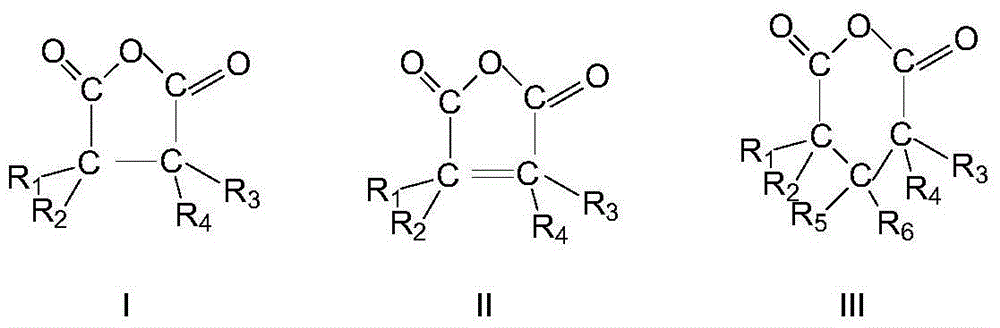

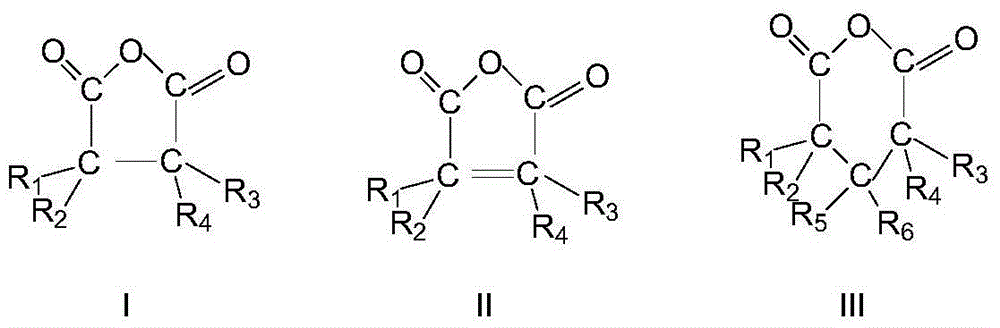

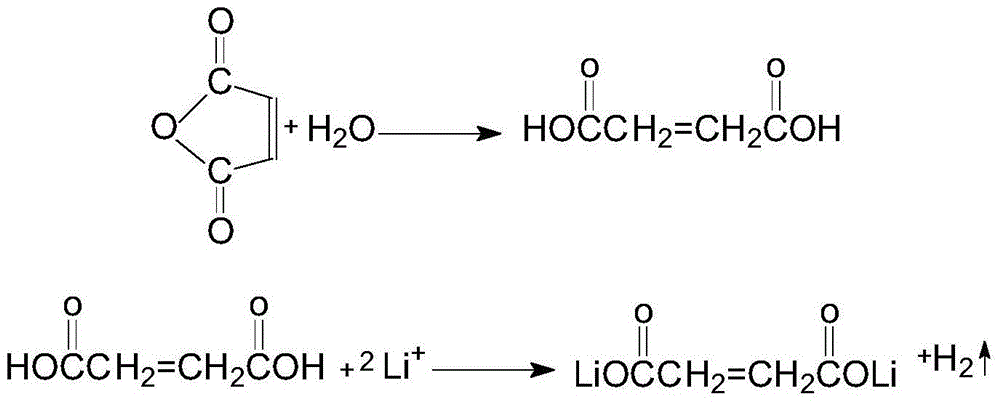

Method used

Image

Examples

Embodiment 1

[0047] The electrolytic solution was prepared in the same manner as in Comparative Example 3, except that 0.5% of the total mass of maleic anhydride was added on this basis to obtain the practical electrolytic solution.

Embodiment 2

[0049] The electrolyte was prepared in the same manner as in Comparative Example 3, except that 0.5% of the total mass of norbornene diacid anhydride was added on this basis to obtain the implementation electrolyte.

Embodiment 3

[0051] The electrolyte was prepared in the same way as in Comparative Example 3, except that 0.5% of the total mass of succinic anhydride was added on this basis to obtain the implementation electrolyte.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com