Metal halide lamp electrode and ceramic metal halide lamp

A ceramic metal halide lamp, metal halide lamp technology, applied in circuits, discharge lamps, electrical components, etc., can solve the problems of radioactive pollution, poor light efficiency, etc., and achieve the effects of long service life, high luminous efficiency, and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] A metal halide lamp electrode and a ceramic metal halide lamp, the structure of the metal halide lamp electrode is as described above and attached figure 2 As shown, the structure of the ceramic metal halide lamp is as described above and attached image 3 shown. Among them, the composition of the emitting ball 15 in the electrode 1 of the metal halide lamp: 0.05wt% hafnium oxide, 1% lanthanum oxide, 6% holmium oxide, and the rest is tungsten, the average diameter is 0.1mm, and the interval is set at The average distance between the adjacent spiral tungsten filaments 131 of the tungsten filament spiral 13 and the two adjacent emitting balls 15 interposed between the same adjacent spiral tungsten filaments 131 is 0.05 mm.

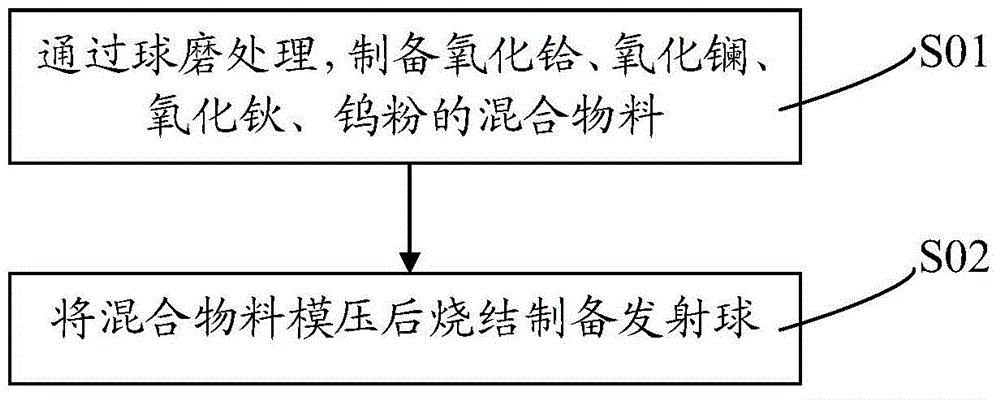

[0047] The preparation method of this launching ball 15 is as follows:

[0048] Put hafnium oxide, lanthanum oxide, holmium oxide, and tungsten metal particle powders with an average particle size range of 3um into a high-energy ball mill according...

Embodiment 2

[0053] A metal halide lamp electrode and a ceramic metal halide lamp, the structure of the metal halide lamp electrode is as described above and attached figure 2 As shown, the structure of the ceramic metal halide lamp is as described above and attached image 3 shown. Among them, the composition of the emitting ball 15 in the metal halide lamp electrode 1: 0.1wt% hafnium oxide, 1wt% lanthanum oxide, 6wt% holmium oxide, the rest is tungsten, its average diameter is 0.2mm, and its interval is set at The average distance between the adjacent spiral tungsten filaments 131 of the tungsten filament spiral 13 and the two adjacent emitting balls 15 interposed between the same adjacent spiral tungsten filaments 131 is 0.07mm.

[0054] The preparation method of the launch ball 15 refers to the preparation method of the launch ball 15 in Example 1, wherein the ball milling process is: the ball milling speed is 180r / min, the ball-to-material ratio is 8:1, the ball filling factor is 5%...

Embodiment 3

[0058] A metal halide lamp electrode and a ceramic metal halide lamp, the structure of the metal halide lamp electrode is as described above and attached figure 2 As shown, the structure of the ceramic metal halide lamp is as described above and attached image 3 shown. Among them, the composition of the emitting ball 15 in the electrode 1 of the metal halide lamp: 0.3wt% hafnium oxide, 1wt% lanthanum oxide, 6wt% holmium oxide, the rest is tungsten, its average diameter is 0.3mm, and its interval is set at The average distance between the adjacent spiral tungsten filaments 131 of the tungsten filament spiral 13 and the two adjacent emitting balls 15 interposed between the same adjacent spiral tungsten filaments 131 is 0.1 mm.

[0059] The preparation method of the launch ball 15 refers to the preparation method of the launch ball 15 in Example 1, wherein the ball milling process is: the ball milling speed is 250r / min, the ball-to-material ratio is 15:1, the ball filling fact...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Grain weight | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com