Friction performance testing device for slipper pair of high-pressure axial plunger pump

An axial piston pump and friction performance technology, which is applied in the field of friction performance testing devices for high-pressure axial piston pump sliding shoe pairs, can solve the problems of high testing cost, burnt sliding shoes, poor oil film performance, etc. And the effect of low cost, adjustable pressure and speed, and simplified experimental device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments, but it is not intended to limit the present invention.

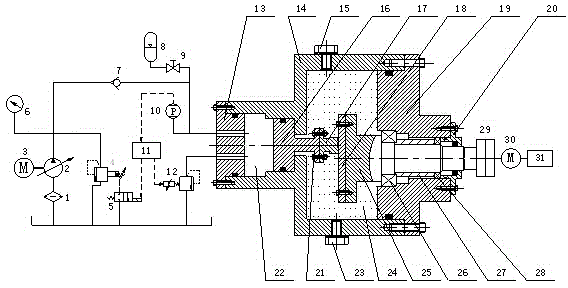

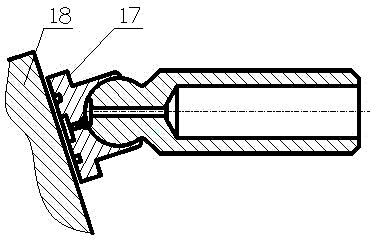

[0026] Embodiment of the present invention: a schematic structural diagram of a device for testing the friction performance of a high-pressure axial piston pump slipper pair of the present invention is as follows: figure 1 As shown in the figure, the device includes a box body 14. During manufacture, a high-pressure oil chamber 22 and an experimental closed chamber 24 are respectively made on the left and right sides of the box body 14, and then the left and right ends of the box body 14 are respectively installed. 13 and the right end cover 19 of the box body, on the left end cover 13 of the box body, the oil inlet connection port and the oil return connection port for connecting with the hydraulic control device are made; The end of the piston rod of 16 is set in the experimental cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com