Stress measurement primary stress separation method and device based on ultrasonic surface wave

An ultrasonic surface wave and stress measurement technology, which is applied in the direction of measuring devices, measuring forces, instruments, etc., can solve problems such as the inability to measure single-point stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

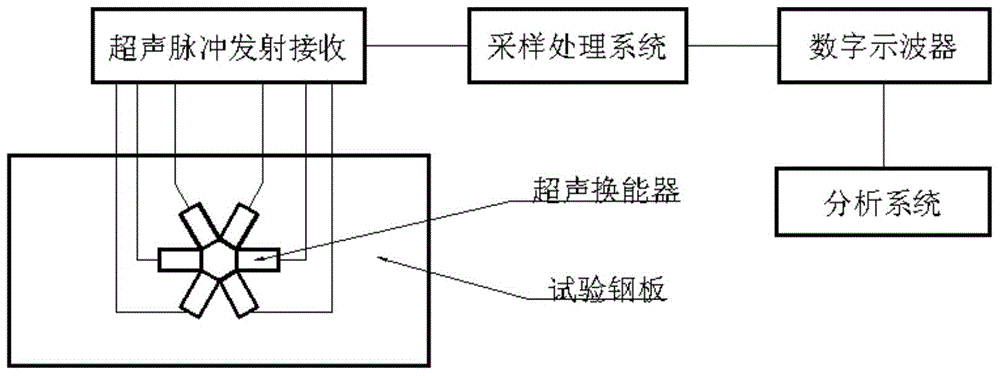

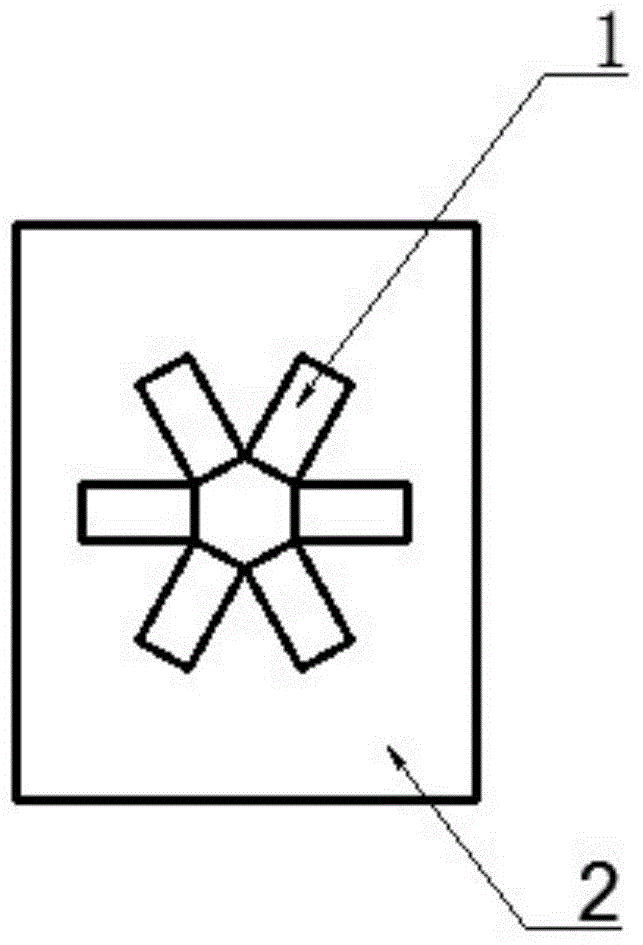

[0034] specific implementation

[0035] The stress measurement principal stress separation includes a separation method and a separation device;

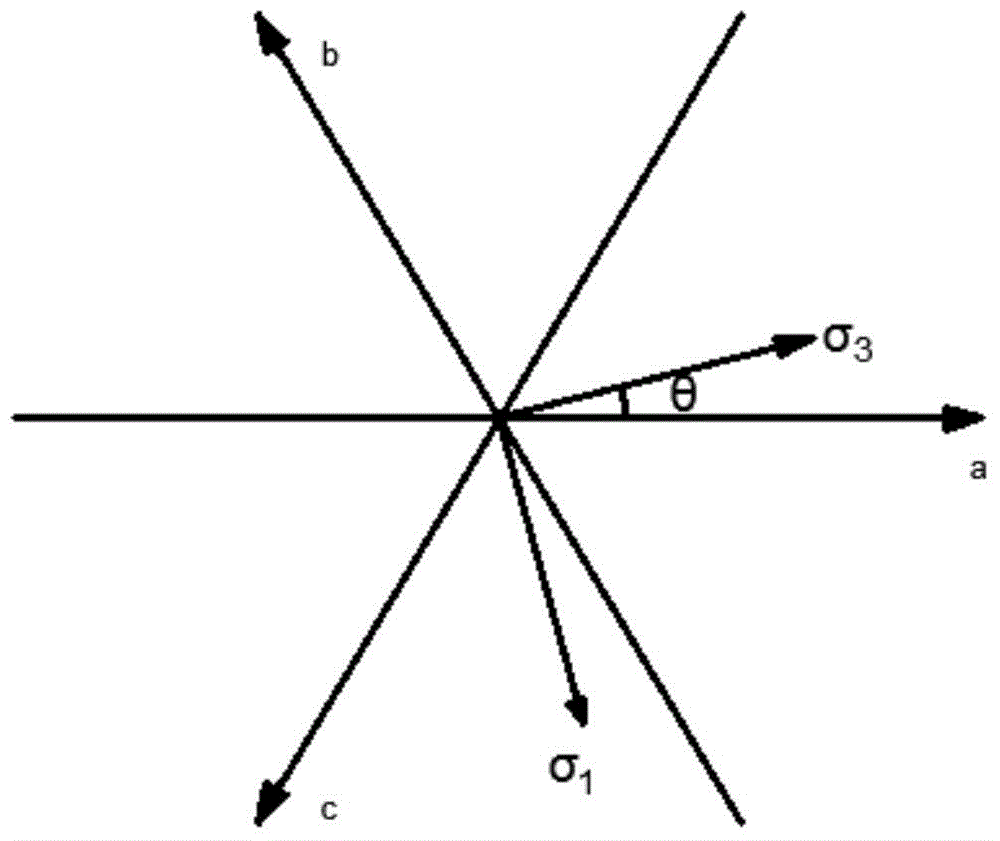

[0036] The described separation method: firstly open the measuring device, apply oil on the surface of the object to be measured as a couplant, place the ultrasonic transducer group on the surface of the object to be measured and fix it, and use the three groups of ultrasonic transducers in the ultrasonic transducer group respectively. The energy detector samples, preprocesses, stores and analyzes the ultrasonic surface wave at the measuring point, calculates the propagation velocity change of the ultrasonic surface wave, thereby obtains the plane two-dimensional stress on the surface of the object, and measures the direction angle of the principal stress and the principal stress. The separation of the ultrasonic surface wave can be expressed as:

[0037] Δt=K 3 σ’ 33 +K 1 σ’ 11 (1)

[0038] where Δt is the propagation time...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com