A Split Spherical Roller Bearing for Heavy Duty Converter Trunnion

A self-aligning roller bearing and splitting technology is applied in the field of bearings to prevent welding slag from easily entering the bearing raceway, ensure the precision of grinding and improve reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

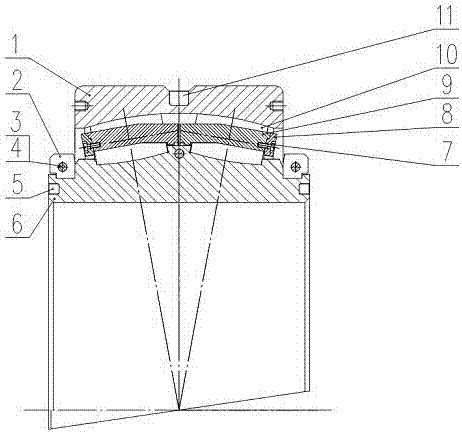

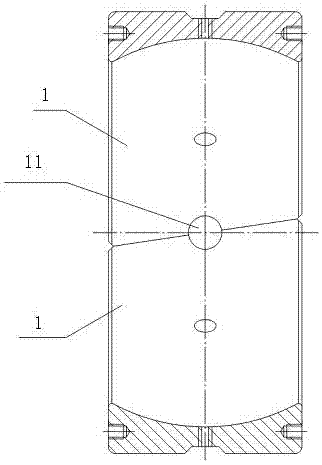

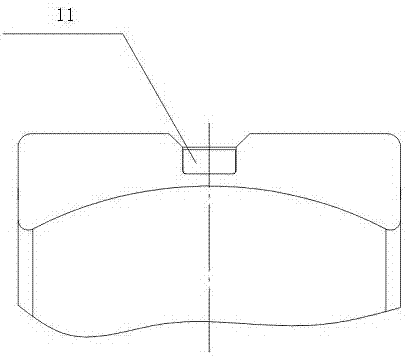

[0023] The specific embodiment of the invention is described with reference to the accompanying drawings.

[0024] Such as figure 1 As shown, a split spherical roller bearing for a heavy-duty converter trunnion, the split spherical roller bearing includes an outer ring, a cage and an inner ring; the outer ring is mounted on a split bearing housing within; combined figure 2 , image 3 , the outer ring is a split structure formed by butting two halves of the outer ring 1; the middle part of the outer surface of the outer ring has an annular oil groove arranged along the circumference of the outer ring; the inner ring is installed on the ear on axis; combined Figure 4 , Figure 5 , the inner ring is a split structure formed by butting two half inner rings 6; on both sides of the outer surface of each half inner ring 6 there are half Tightening ring 2; the cages are respectively provided for each row of rollers of the split spherical roller bearings, and there is a gap bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com