Auxiliary supporting and sliding guiding mechanism for ejection of rear mold push plate

A technology of auxiliary support and rear mold, which is applied in the field of mold equipment, can solve the problems of self-heaviness of the rear mold, deformation and fracture of guide pillars, etc., and achieve the effect of simple structure, enhanced stability and convenient replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

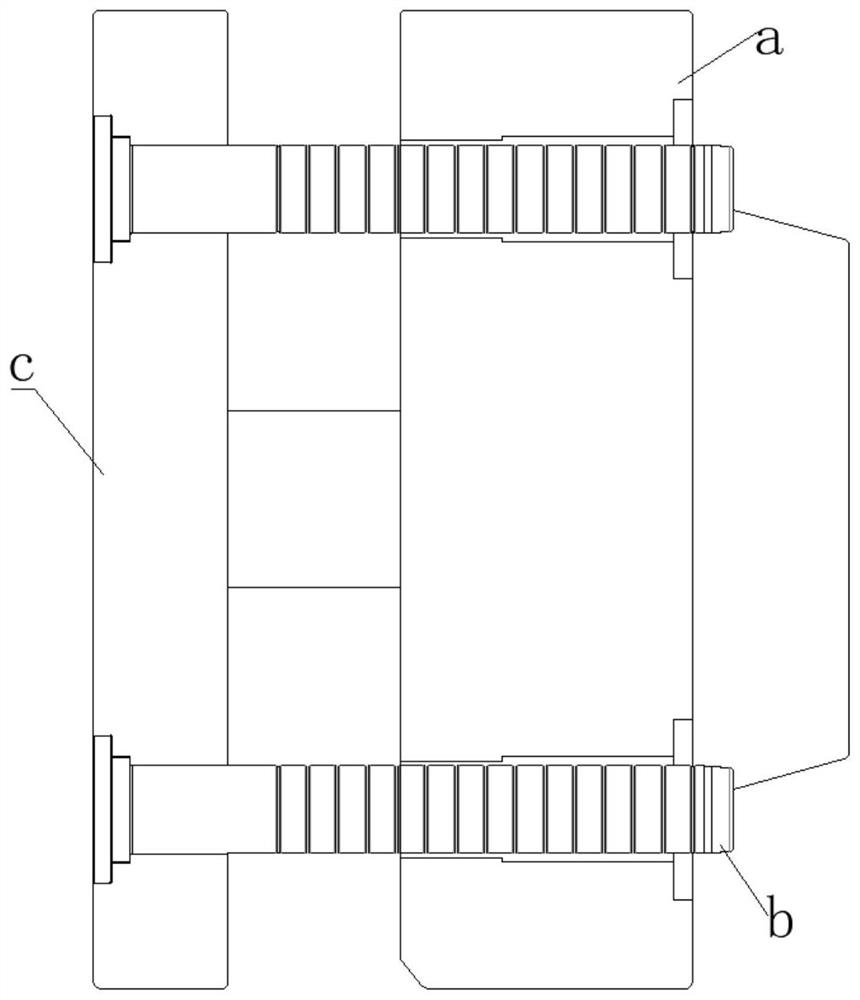

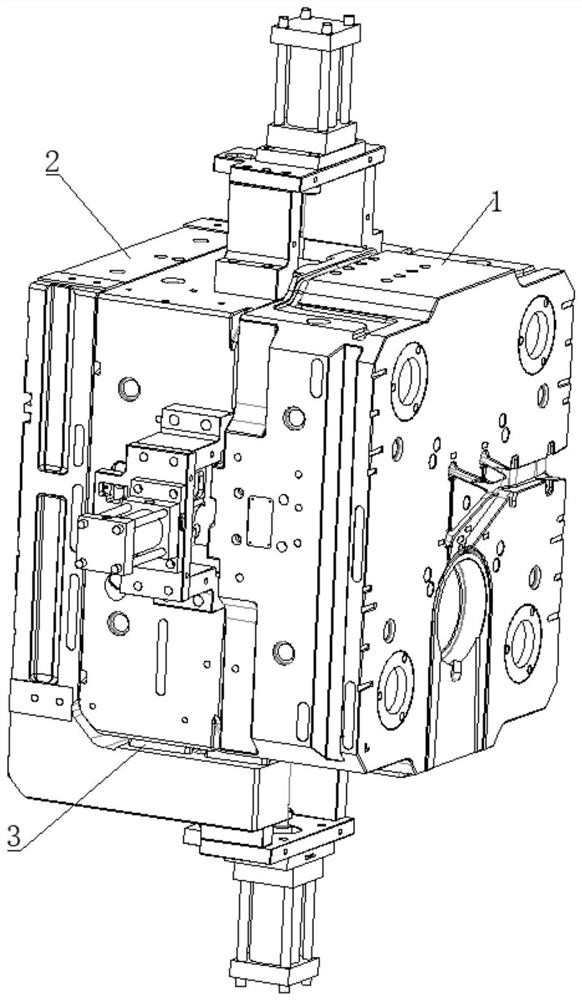

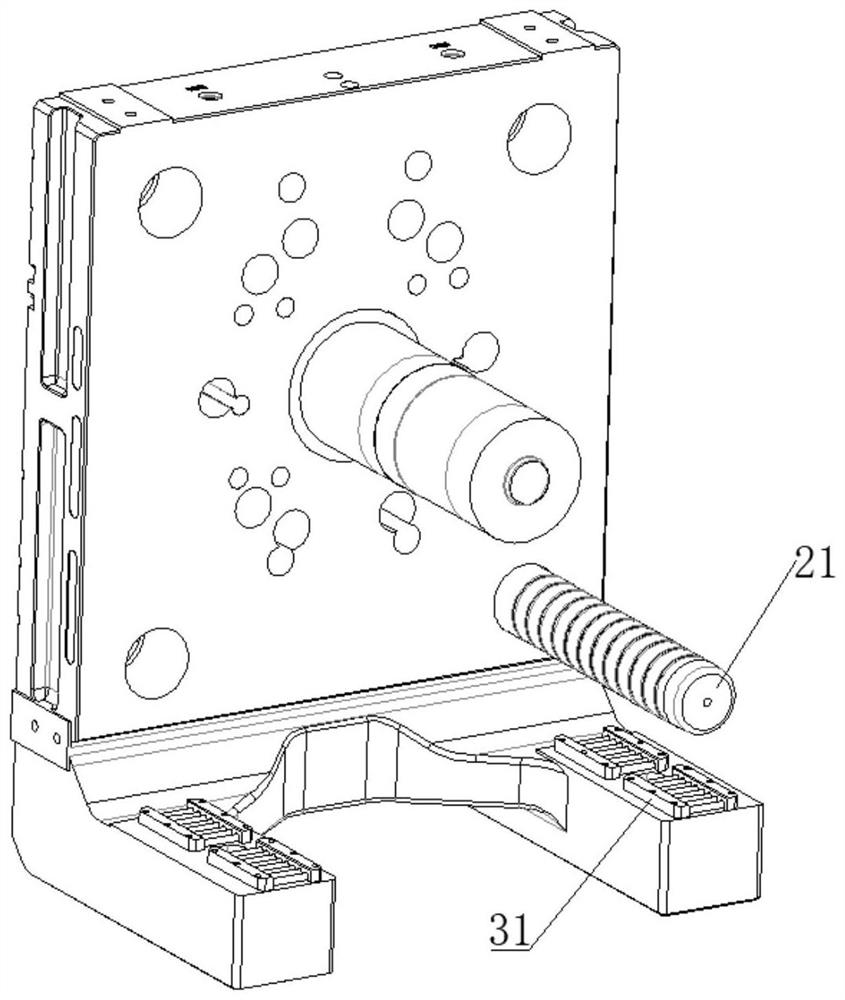

[0027] refer to Figure 1-Figure 6 As shown, an auxiliary support and slide guide mechanism for the ejection of a rear mold push plate of the present invention includes a rear mold 1, a rear mold bottom plate 2 and a guide slide assembly 3, and the rear mold bottom plate 2 is L-shaped, including a horizontal part and a vertical Straight part, a plurality of horizontal guide pillars 21 are arranged symmetrically on the vertical part of the back mold bottom plate 2, the back mold 1 is slidably connected with the back mold bottom plate 2 through the guide pillars 21, and the guide slide assembly 3 is used to assist the back mold 1 along the guide rail. The column 21 moves, and the sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com