Repair technology for drainage pressure reducing well

A technology for draining decompression and decompression wells, which is applied in dams, infrastructure projects, embankments, etc., and can solve problems such as skeleton fracture, strip skeleton aging, and failure to use normally.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

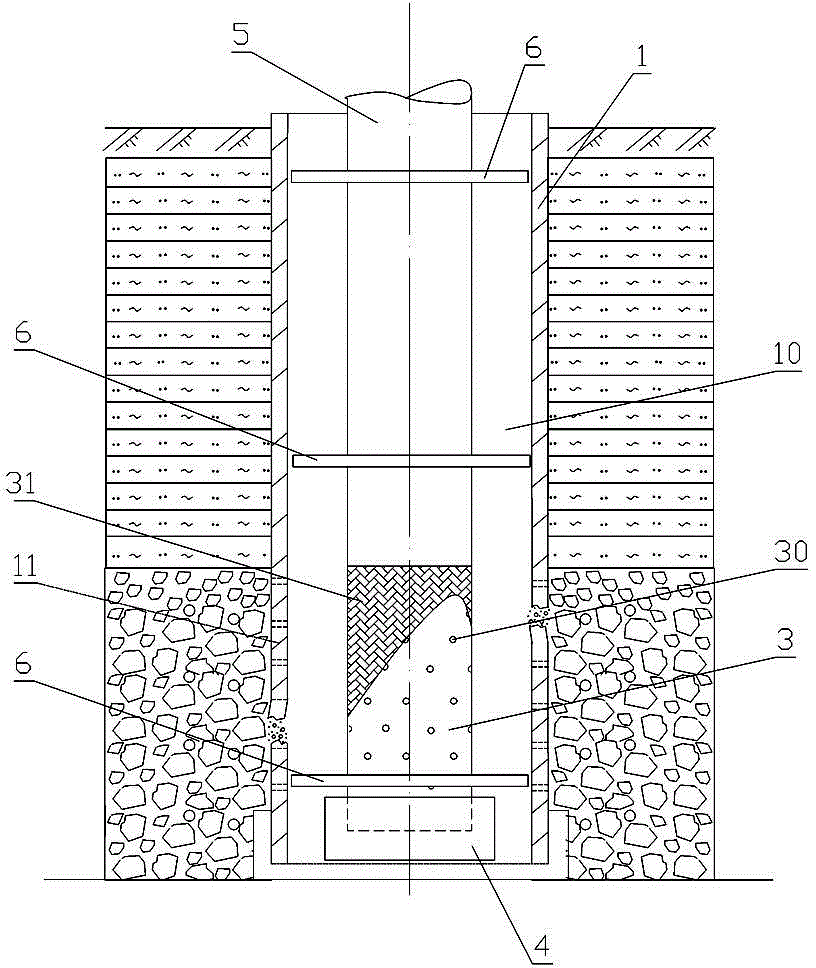

[0023] refer to Figure 2 to Figure 5 , the repairing process of drainage relief well, comprising the following steps.

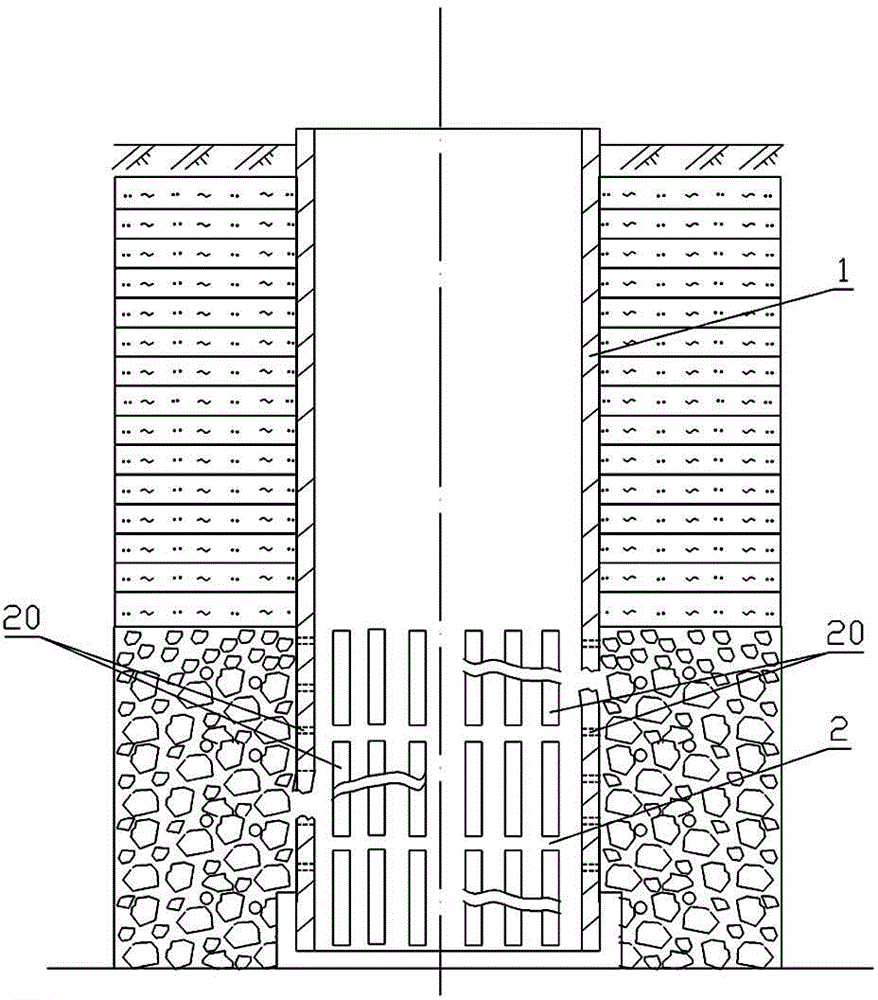

[0024] Step 1), cleaning in the original well: use the cleaning process of the relief well to discharge the sedimentation, sundries and sewage in the well pipe 1 of the original relief well out of the pipe 1 until it is cleaned.

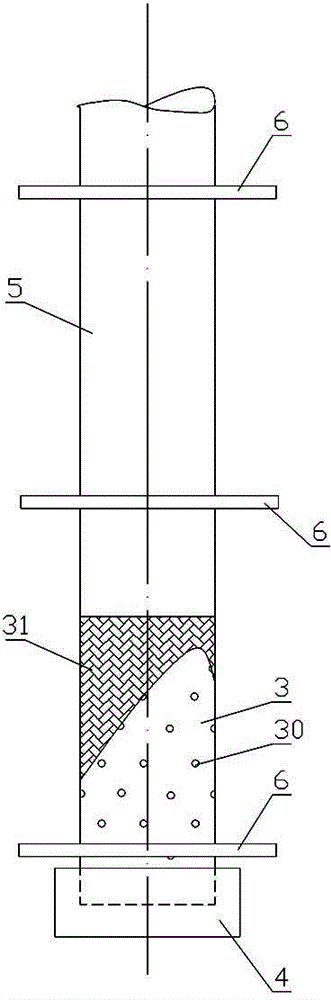

[0025] Step 2), intubation tube preparation: such as figure 2 As shown, the intubation pipe tool includes a pipe plug 4, a filter pipe 3, a filter screen 31, a riser pipe 5 and a steel retainer 6, and the length of the filter pipe 3 is 0.6 mm longer than the original filter pipe 11 of the original relief well pipe 1. The outer wall of the filter tube 3 is evenly distributed with filter holes 30, the outer wall of the filter tube 3 is coated with a filter screen 31, the bottom end of the filter tube 3 is provided with a pipe plug 4, and the top of the filter tube 3 is connected to the top of the water riser 5. The bottom end is c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com