Environment-friendly type production method of water transfer printing body paper

A production method, water transfer printing technology, applied in the direction of paper, papermaking, paper coating, etc., can solve the problems of unfavorable energy saving and emission reduction, fragile ecological environment, and large wood consumption, so as to realize the recycling of waste resources and reduce production costs , the effect of saving wood

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The main raw material is waste paper that meets the first-level standard of the national waste paper classification standard (SB / T11058-2013).

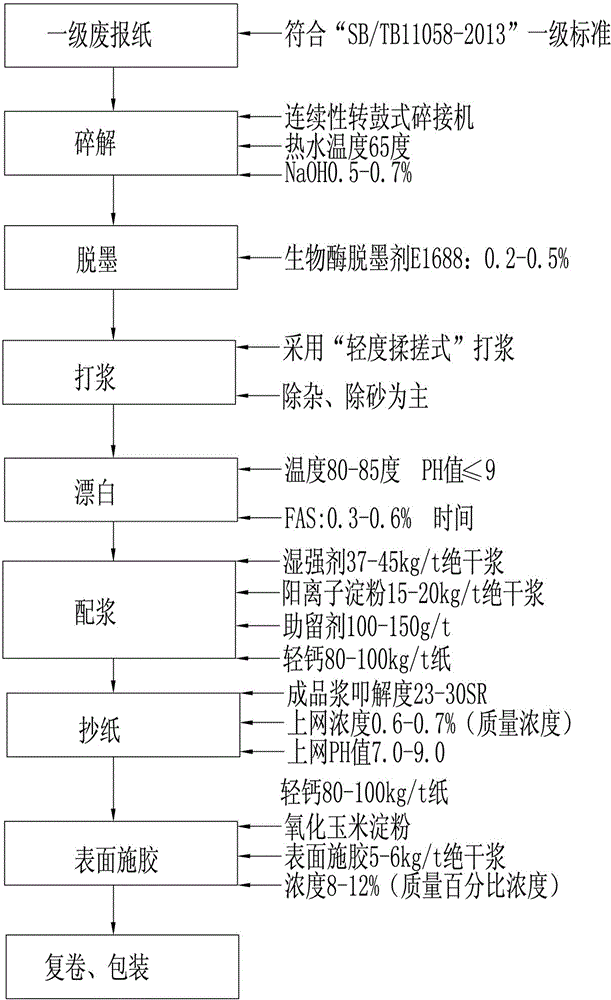

[0027] Its main process steps process conditions are as follows:

[0028] 1. Disintegration: Send high-quality waste newspapers into the drum pulper, and add hot water and alkali at the same time; the temperature of hot water is 60°C, the alkali is NaOH, and the amount of NaOH added is 0.5% (mass concentration), the high-quality waste Newspapers are waste paper that meets the first-level standard of the national waste paper classification standard (SB / T11058-2013).

[0029] 2. Deinking: The waste paper pulp obtained in process "1" is added to a deinking agent for deinking; the deinking agent is selected from the biological enzyme deinking agent E1688, and the addition amount is 0.2% in mass concentration.

[0030] 3. Beating: The pulp deinked in process "2" is subjected to "mild rubbing" beating. The beating is mainly to remov...

Embodiment 2

[0044] Example 2: The main raw material is waste paper that meets the first-level standard of the national waste paper classification standard (SB / T11058-2013);

[0045] Its main process steps process conditions are as follows:

[0046] 1. Disintegration: Send high-quality waste newspapers to the drum pulper, and add hot water and alkali at the same time; the temperature of hot water is 70°C, the alkali is NaOH, and the amount of NaOH added is 0.7% (mass concentration).

[0047] 2. Deinking: The waste paper pulp obtained in process "1" is added to a deinking agent for deinking; the deinking agent is selected from the biological enzyme deinking agent E1688, and the addition amount is 0.5% in mass concentration.

[0048] 3. Beating: The pulp deinked in process "2" is subjected to "mild rubbing" beating. The beating is mainly to remove impurities and sand, avoid excessive shearing of fibers, and protect the length and strength of regenerated fibers.

[0049] 4. Bleaching: FAS bl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Knocking degree | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Tightness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com