A method for rapid boronizing of q235 steel

A boronizing and rapid technology, applied in the direction of coating, metal material coating process, solid-state diffusion coating, etc., can solve the problems of long time, difficult to obtain single-phase Fe, high temperature, etc., achieve good hardness gradient and shorten boronizing The effect of time and high density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

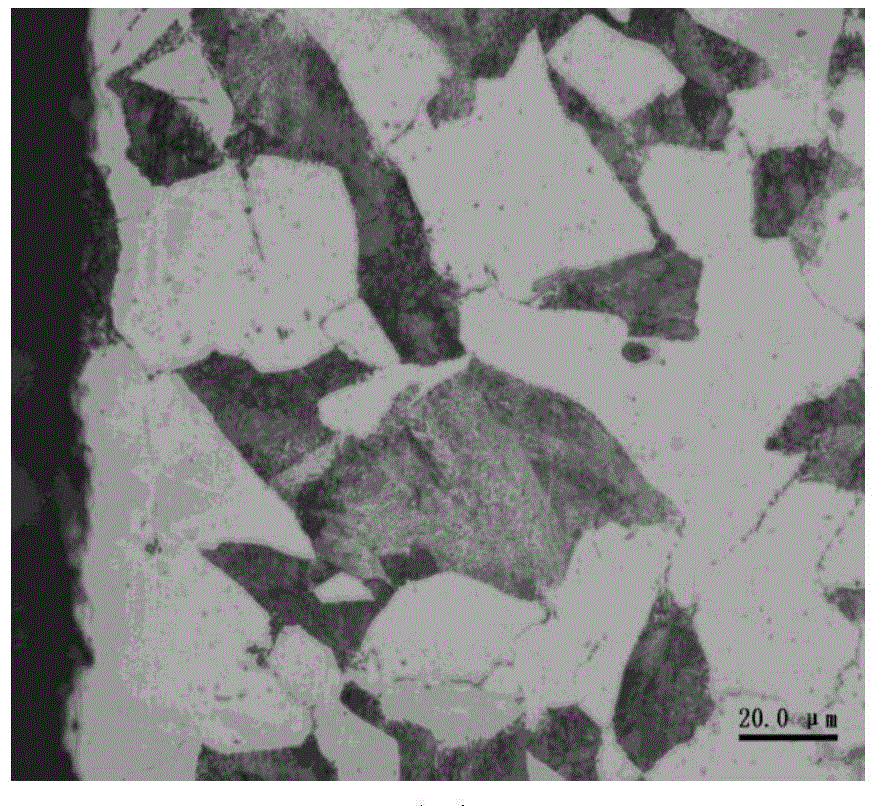

[0054] The Q235 steel is subjected to single-sided surface shot peening with supersonic particle bombardment technology. The process is: working air pressure 0.5MPa, S110 stainless steel projectiles with a diameter of 0.3mm, and the bombardment time is 30min, so that the structure of the shot peening surface is refined to nanometers. level; then the Q235 steel after shot blasting is cleaned with acetone in an ultrasonic cleaner to keep the surface of the Q235 steel sample clean;

[0055] In mass fraction, take by weighing 10% diboron trioxide, 10% ammonium bicarbonate, 10% cerium oxide, 15% active carbon, 55% silicon carbide and mix uniformly to prepare powder boronizing agent, and Dry the powder boronizing agent at 100°C for 1h; dry the boronizing sealed pot at 100°C for 1h, bury Q235 steel in the boronizing sealed tank containing the above powder boronizing agent, and put it in the muffle furnace Heat to 550°C, hold for 2 hours, then heat up to 800°C with the furnace and con...

Embodiment 2

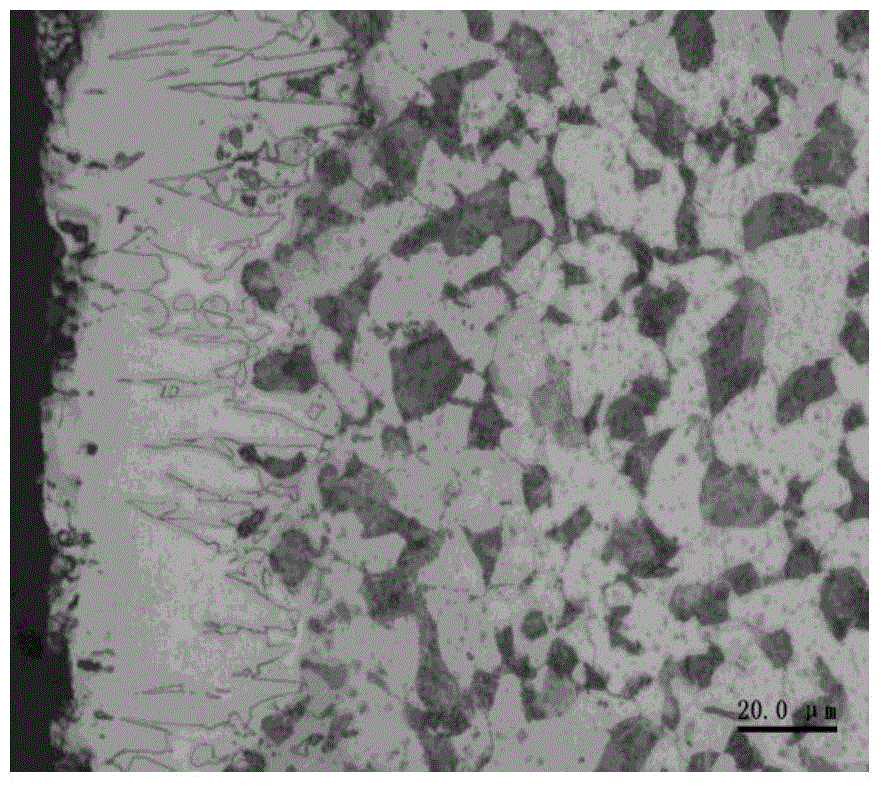

[0058] The Q235 steel is subjected to single-sided surface shot peening with supersonic particle bombardment technology. The process is: working air pressure 0.5MPa, S110 stainless steel projectiles with a diameter of 0.3mm, and the bombardment time is 30min, so that the structure of the shot peening surface is refined to nanometers. level; then the Q235 steel after shot blasting is cleaned with acetone in an ultrasonic cleaner to keep the surface of the Q235 steel sample clean;

[0059] In terms of mass fraction, weigh 12% ferroboron, 13% potassium fluoride, 8% cerium oxide, 20% activated carbon, and 47% silicon carbide and mix uniformly to prepare a powder boronizing agent, and the powder Dry the boronizing agent at 100°C for 1h; dry the boronizing sealed pot at 100°C for 1.5h, bury the Q235 steel in the boronizing sealed pot containing the above powder boronizing agent, and heat it in a muffle furnace Heat to 580°C, hold for 1.5h, then heat up to 900°C with the furnace and ...

Embodiment 3

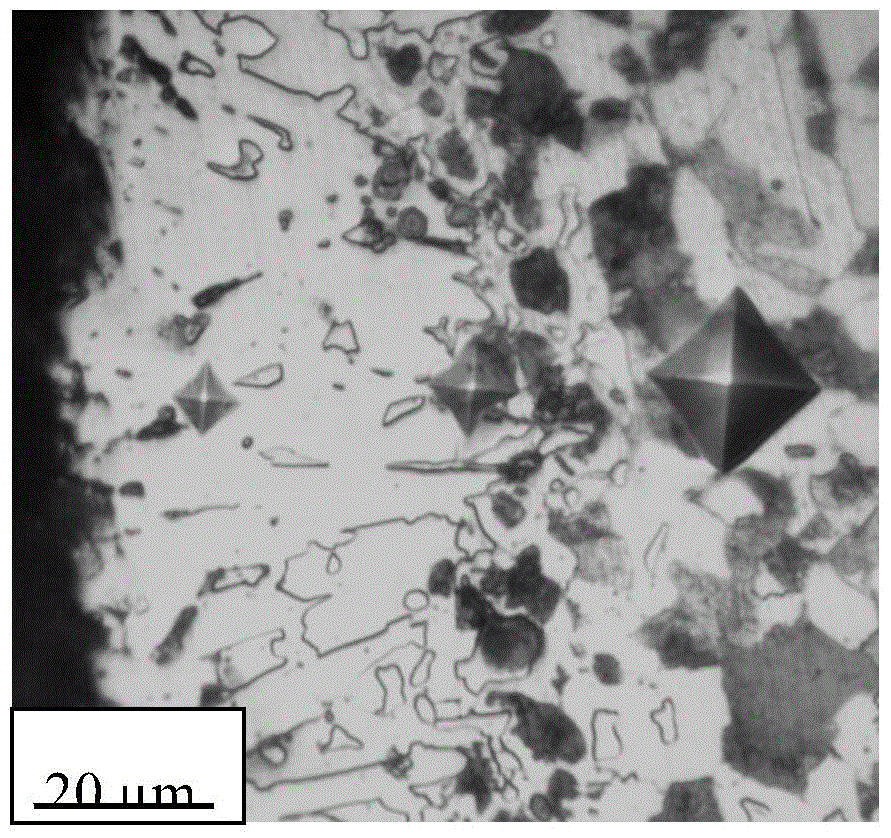

[0062] The Q235 steel is subjected to single-sided surface shot peening with supersonic particle bombardment technology. The process is: working air pressure 0.5MPa, S110 stainless steel projectiles with a diameter of 0.3mm, and the bombardment time is 30min, so that the structure of the shot peening surface is refined to nanometers. level; then the Q235 steel after shot blasting is cleaned with acetone in an ultrasonic cleaner to keep the surface of the Q235 steel sample clean;

[0063] In mass fraction, take by weighing 15% boron carbide, 15% sodium fluorosilicate, 12% cerium oxide, 18% active carbon, 40% silicon carbide and mix uniformly to prepare powder boronizing agent, and Dry the powder boronizing agent at 100°C for 1h; dry the boronizing sealed pot at 100°C for 1.2h, bury the Q235 steel in the boronizing sealed tank containing the above powder boronizing agent, and put it in the muffle furnace After heat preservation at 600°C for 2 hours, the furnace temperature was r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com