Special low-temperature-resistant corrosion-resistant crude oil storage tank cleaning agent and preparation method thereof

A technology for crude oil storage tanks and low temperature resistance, which is applied in chemical instruments and methods, detergent compounding agents, detergent compositions, etc., and can solve problems such as reducing the service life of storage tanks, environmental secondary pollution, and poor cleaning effects. Achieve good corrosion resistance, prolong service life, and excellent cleaning performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

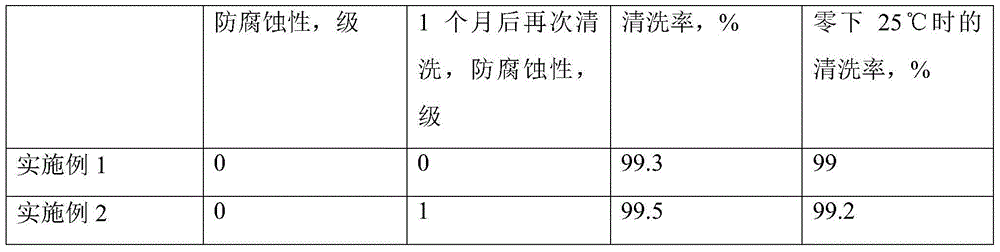

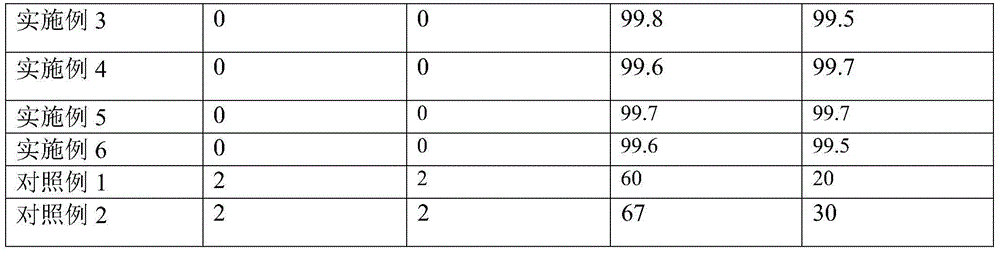

Examples

Embodiment 1

[0025] Low-temperature and corrosion-resistant cleaning agent for crude oil storage tanks, including the following raw materials in parts by mass: 13 parts of onion silk, 10 parts of orange peel, 2 parts of N,N'-diallyl-L-tartaramide, limonene 14 parts, 1 part of polyaspartic acid, 5 parts of nano silicon powder, 1 part of sodium tetraborate, 1 part of sodium citrate, 6 parts of borneol, 24 parts of ethanol, and 100 parts of water.

[0026] The preparation method of the special low-temperature and corrosion-resistant cleaning agent for crude oil storage tanks comprises the following steps:

[0027] Step 1: According to the number of parts by mass, crush the onion silk and orange peel to 100 mesh, add it to ethanol, raise the temperature to 60°C, soak for 5 hours, and then filter to get the filtrate, and then sequentially add N,N'-diallyl- L-tartrate amide, limonene and polyaspartic acid were added in the filtrate, and stirred evenly to obtain mixture A;

[0028] Step 2: addin...

Embodiment 2

[0031] Low-temperature and corrosion-resistant cleaning agent for crude oil storage tanks, including the following raw materials in parts by mass: 17 parts of onion silk, 20 parts of orange peel, 6 parts of N,N'-diallyl-L-tartaramide, limonene 16 parts, 2 parts of polyaspartic acid, 10 parts of nano silicon powder, 4 parts of sodium tetraborate, 2 parts of sodium citrate, 9 parts of borneol, 27 parts of ethanol, 140 parts of water.

[0032] The preparation method of the special low-temperature and corrosion-resistant cleaning agent for crude oil storage tanks comprises the following steps:

[0033] Step 1: According to the number of parts by mass, crush the onion silk and orange peel to 200 mesh, add it to ethanol, raise the temperature to 70°C, soak for 2 hours, then filter to get the filtrate, and then sequentially add N,N'-diallyl- L-tartrate amide, limonene and polyaspartic acid were added in the filtrate, and stirred evenly to obtain mixture A;

[0034] Step 2: adding na...

Embodiment 3

[0037] Low-temperature and corrosion-resistant cleaning agent for crude oil storage tanks, including the following raw materials in parts by mass: 14 parts of onion silk, 12 parts of orange peel, 3 parts of N,N'-diallyl-L-tartaramide, limonene 14 parts, 1 part of polyaspartic acid, 6 parts of nano silicon powder, 1 part of sodium tetraborate, 1 part of sodium citrate, 7 parts of borneol, 25 parts of ethanol, and 105 parts of water.

[0038] The preparation method of the special low-temperature and corrosion-resistant cleaning agent for crude oil storage tanks comprises the following steps:

[0039] Step 1: According to the number of parts by mass, crush the shallot and orange peel to 150 mesh, add it to ethanol, raise the temperature to 62°C, soak for 3 hours, and then filter to get the filtrate, and then sequentially add N,N'-diallyl- L-tartrate amide, limonene and polyaspartic acid were added in the filtrate, and stirred evenly to obtain mixture A;

[0040] Step 2: adding n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com