Fuel economy engine oil composition

A lubricating oil composition, overalkaline technology, applied in lubricating compositions, base materials, petroleum industry, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

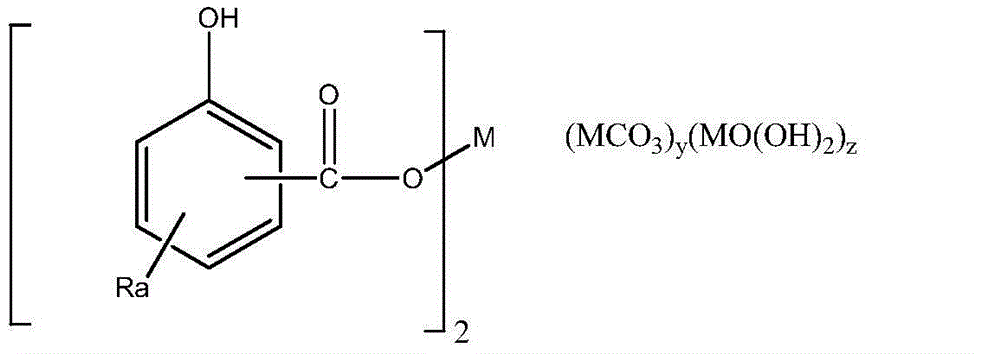

Method used

Image

Examples

Embodiment 1-4 and comparative example A-D

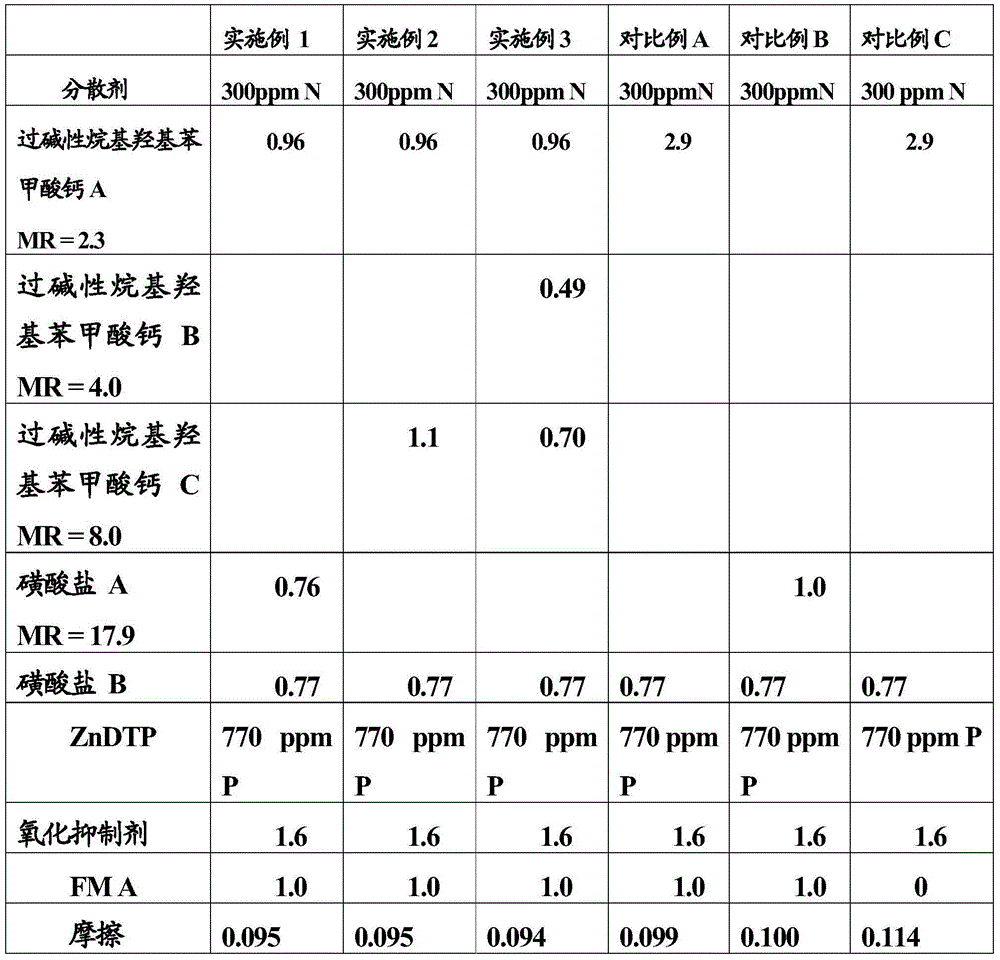

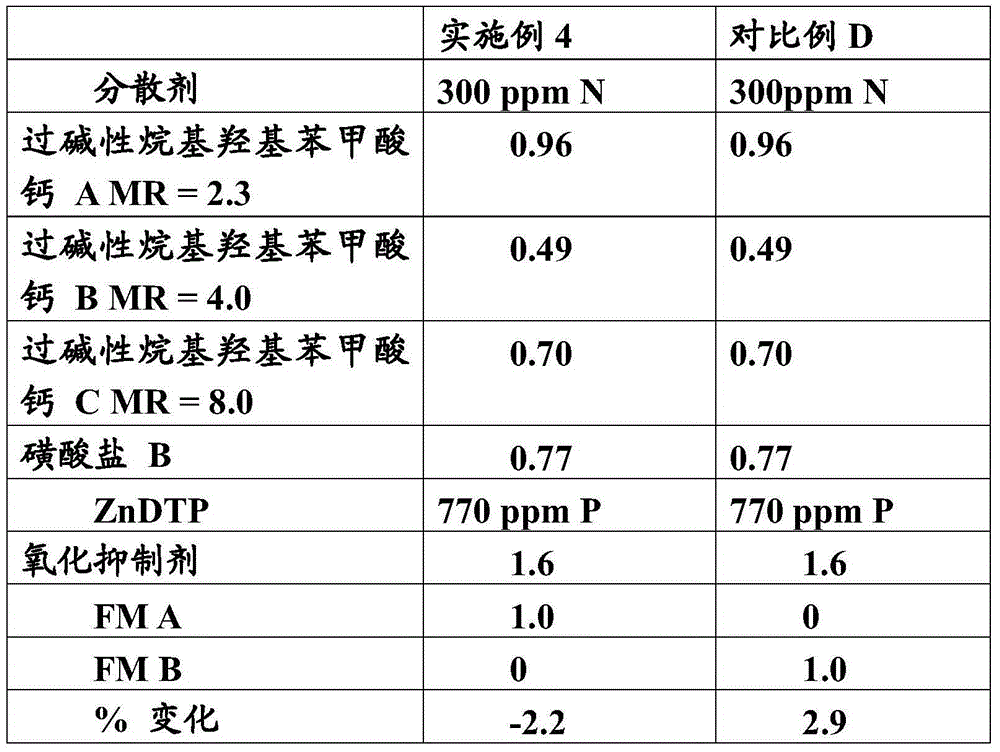

[0126] Lubricating oil compositions were prepared by adding the below-mentioned additive components to the base oils to give the formulations described in Tables 1 and 2. The lubricating oil compositions of Examples 1-4 are in accordance with the present invention, while Comparative Examples A-D are provided for comparison and are not in accordance with the present invention. Examples 1-3 and Comparative Examples A-C were formulated to achieve a SAE viscosity grade of 0W-20 (as defined in SAE J300, January 2009 edition). Their kinematic viscosity at 100°C is 7.7-7.8mm 2 / s. Example 4 and Comparative Example D were formulated to achieve an SAE viscosity grade of 0W-4. Their kinematic viscosity at 100°C is 3.1mm 2 / s.

[0127] base oil –

[0128] a) Examples 1-3 and Comparative Examples A-C: Mineral base oils prepared by vacuum distillation, isomerization dewaxing and hydrofining (kinematic viscosity is 4.2mm at 100°C 2 / s, the viscosity index is 130).

[0129] b) Example...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Kinematic viscosity | aaaaa | aaaaa |

| Kinematic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com