Method for extracting loropetalum chinense flower red pigment by adopting acetic acid-microwave process

A technology of rhododendron and rhododendron, which is applied in the field of extracting rhododendron rhododendron by adopting an acetic acid-microwave process, can solve the problems of easy destruction of heat-sensitive components, large energy consumption of raw material pretreatment, large loss of organic solvent, etc., and the extraction time is reached. Shortening, small damage, avoiding the effect of catalytic oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

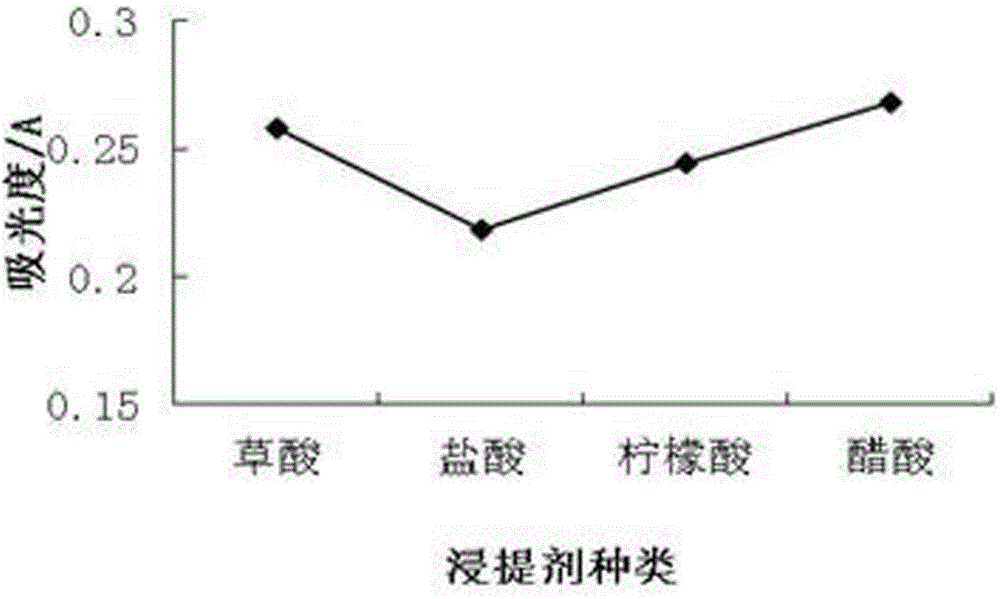

[0033] Example 1: Effects of Different Extracting Agents on the Microwave Extraction of Red Pigment

[0034] The method for extracting the red pigment of the eucalyptus by microwave using different extractants, the specific steps are as follows:

[0035] Place the fresh red sage flower in a vacuum drying oven, and after drying at a constant temperature of 40°C, weigh 10 g of the dried red sage flower, pulverize it in a pulverizer, and pass it through a 100-mesh sieve to obtain dried sage flower powder.

[0036] Weigh 4 parts of dried safflower powder 1g and place them in four 50ml Erlenmeyer flasks, and add citric acid, oxalic acid and hydrochloric acid respectively according to the ratio of solid to liquid (flower mass g / solvent volume ml) as 1g:10ml and acetic acid (all acids contain 1% sodium aminotriacetate and 1% sodium metabisulfite, and the concentration of each acid is 20%), soak at room temperature for 20 minutes, and then microwave extraction twice, each extraction t...

Embodiment 2

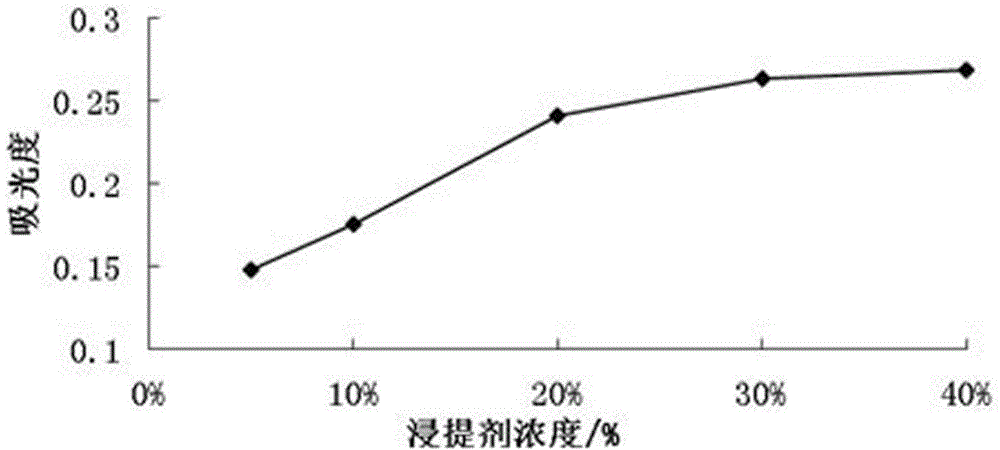

[0038] Embodiment 2: the influence of acetic acid concentration on microwave extraction of red pigment

[0039] A kind of method that adopts acetic acid-microwave process of the present invention to extract the red pigment of the eucalyptus, concrete steps are as follows:

[0040] Put the fresh red sage flower in a vacuum drying oven, after drying at a constant temperature of 40°C, weigh 10g of the dried red sage flower, pulverize it in a pulverizer, and then pass it through a 100-mesh sieve to obtain dried sage flower powder.

[0041] Weigh 5 parts of dried safflower powder 1g and place it in five 50ml Erlenmeyer flasks, and add different concentrations of acetic acid ( Contains 1% sodium aminotriacetate and 1% sodium metabisulfite, acetic acid concentrations are 5%, 10%, 20%, 30%, 40%, soak at room temperature for 20 minutes, and then microwave extraction twice, each extraction time is 1 minute. After the leaching finishes, let it cool down to room temperature naturally, fi...

Embodiment 3

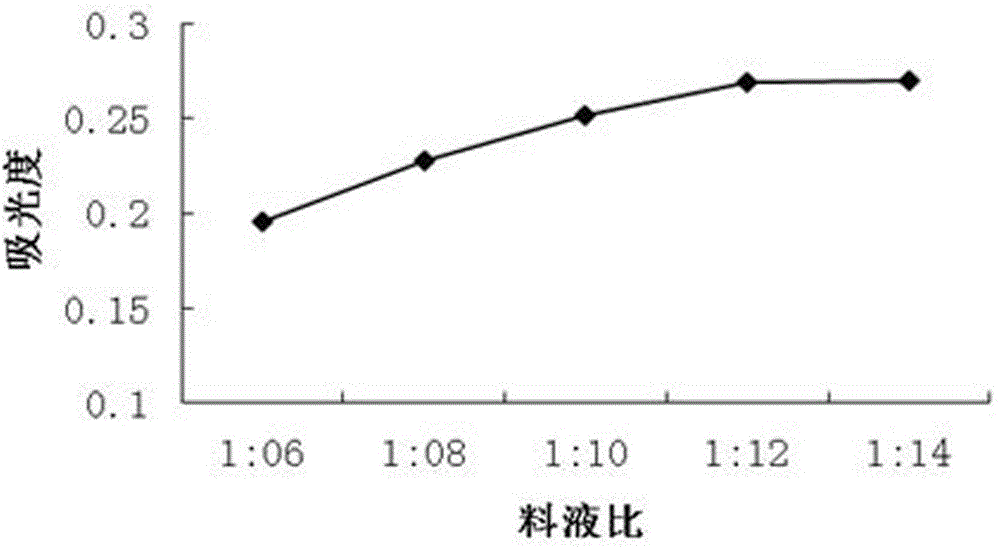

[0043] Embodiment 3: The influence of solid-liquid ratio on red pigment microwave extraction

[0044] A kind of method that adopts acetic acid-microwave process of the present invention to extract the red pigment of the eucalyptus, concrete steps are as follows:

[0045] Put the fresh red sage flower in a vacuum drying oven, after drying at a constant temperature of 40°C, weigh 15g of the dried red sage flower, pulverize it in a pulverizer, and pass it through a 100-mesh sieve to obtain dried sage flower powder.

[0046] Weigh 5 parts of dried safflower powder 1g and place them in five 50ml Erlenmeyer flasks, respectively according to the ratio of material to liquid (flower powder mass g / solvent volume ml) 1:6, 1:8, 1:10 , 1:12, 1:14, add 40% acetic acid (containing 1% sodium aminotriacetate and 1% sodium metabisulfite), soak at room temperature for 20 minutes, and then microwave extraction twice, each extraction time is 1 minute. After leaching finishes, allow it to cool nat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com