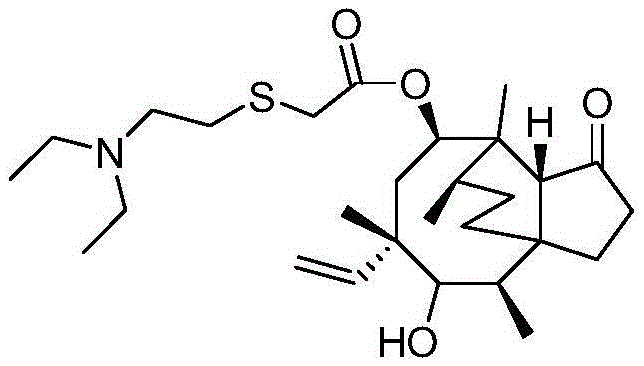

One-pot method for synthesizing tiamulin

A technology of tiamulin and truncated pleuromutilin ester, which is applied in the field of chemical synthesis of veterinary raw materials, can solve the problems of difficult purchase, high price, and restriction of tiamulin production, and achieve low cost, simple operation, Environmentally friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

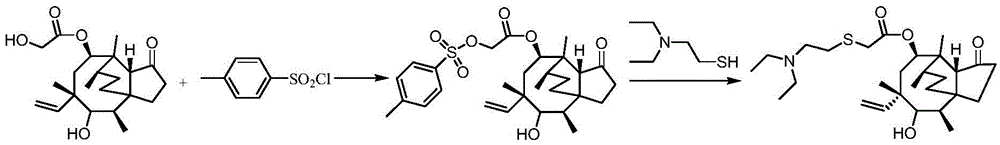

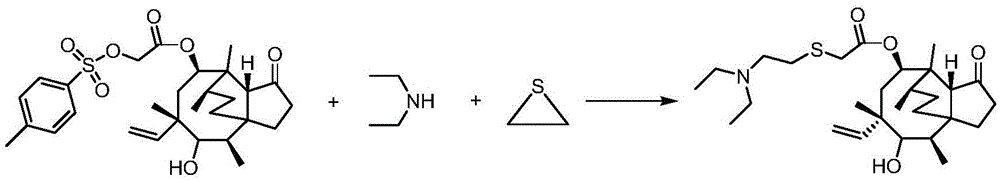

Method used

Image

Examples

Embodiment 1

[0017] Add 0.532g (1.0mmol) pleuromutilin p-toluenesulfonate, 1mL ethyl acetate, 155μL (1.5mmol) diethylamine, 98μL (1.6mmol) sulfide into the reaction flask, Under stirring and reflux for 4 hours, ethyl acetate was evaporated, and the residue was separated by silica gel column chromatography (the mobile phase was a mixture of ethyl acetate and sherwood oil with a volume ratio of 1:3), to obtain 0.268g tiamulin. The rate is 54.2%.

Embodiment 2

[0019] In Example 1, the ethyl acetate used was replaced with an equal volume of ethylene glycol dimethyl ether, and other steps were the same as in Example 1 to obtain 0.228 g of tiamulin with a yield of 46.1%.

Embodiment 3

[0021] In Example 1, the ethyl acetate used was replaced with an equal volume of methyl isobutyl ketone, and other steps were the same as in Example 1 to obtain 0.201 g of tiamulin with a yield of 40.6%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com