Kiwi fruit liquid swelling nutrition mixture and its preparation method and application

The technology of a nutritional mixture and kiwifruit, which is applied in the field of crop cultivation, can solve the problems such as the inappropriate use of bulking agents, and achieve the effects of convenient metering, watering and use, and outstanding bulking effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

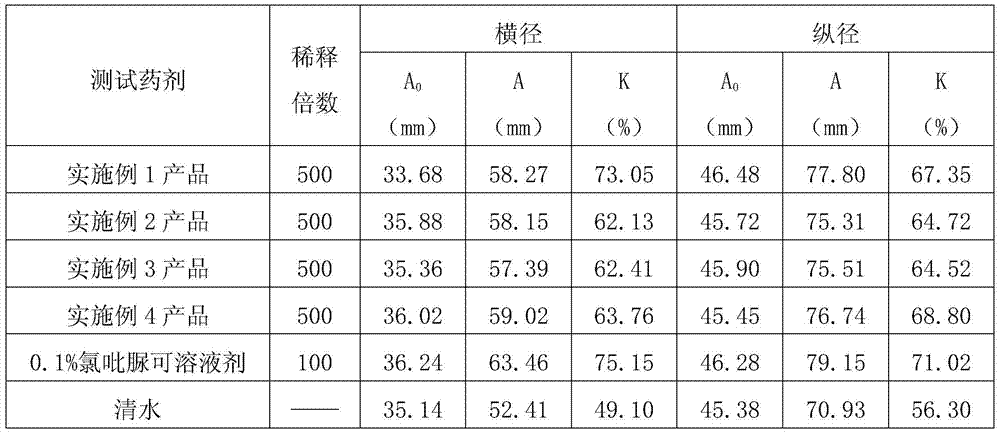

Examples

preparation example Construction

[0036] The preparation method of kiwifruit liquid expansion nutrient mixture of the present invention comprises the steps:

[0037] a. Chelate potassium magnesium sulfate and glycine in water at 80-120°C for 1-5 hours to obtain a chelate of potassium magnesium sulfate and glycine; chelate potassium dihydrogen phosphate and mannitol in water at 80-120°C 1-5 hours to get the chelate of potassium dihydrogen phosphate and mannitol; chelate ammonium dihydrogen phosphate and glucose in water at 75-85°C for 5 hours to get the chelate of ammonium dihydrogen phosphate and glucose;

[0038] B, the chelate of potassium magnesium sulfate and glycine, the chelate of potassium dihydrogen phosphate and mannitol, the chelate of ammonium dihydrogen phosphate and glucose, urea, EDTA-Zn, EDTA-Ca, EDTA-Cu, Boric acid, organic acid, water-soluble non-ionic surfactant and water are mixed and dissolved to obtain kiwi fruit liquid swelling nutrition mixture.

[0039] In order to improve the swelling...

Embodiment 1

[0049] Product formula: potassium magnesium sulfate 14%, glycine 1.3%, potassium dihydrogen phosphate 21%, mannitol 2.1%, urea 7%, ammonium dihydrogen phosphate 16%, glucose 1.7%, EDTA-Zn 1.2%, EDTA-Ca 4 %, EDTA-Cu 0.8%, boric acid 1%, citric acid 2%, tea saponin 2%, deionized water 25.9%.

[0050] Send potassium magnesium sulfate, glycine and 6% deionized water to the stirring reaction kettle, then seal it well and turn on the condensing reflux device to start stirring. At the same time, turn on the steam to raise the temperature. When the temperature rises to 90°C, start timing, and adjust the amount of steam to control the temperature. Between 90-98°C, react for 2 hours, pass cooling water after the reaction to lower the temperature in the kettle to below 40°C, and obtain a chelate of potassium magnesium sulfate and glycine;

[0051] Send potassium dihydrogen phosphate, mannitol and 6% deionized water to the stirred reactor, then seal it well and turn on the condensing refl...

Embodiment 2

[0055] Product formula: potassium magnesium sulfate 11%, glycine 1%, potassium dihydrogen phosphate 17%, mannitol 1.7%, urea 5.6%, ammonium dihydrogen phosphate 19%, glucose 2%, EDTA-Zn 1.5%, EDTA-Ca 4.8 %, EDTA-Cu 1%, boric acid 1.2%, citric acid 2.4%, tea saponin 2.4%, deionized water 29.4%.

[0056] Send potassium magnesium sulfate, glycine and 6% deionized water to the stirring reaction kettle, then seal it well and turn on the condensing reflux device to start stirring. At the same time, turn on the steam to raise the temperature. When the temperature rises to 80°C, start timing, and adjust the amount of steam to control the temperature. Between 80-85°C, react for 5 hours. After the reaction, pass cooling water to reduce the temperature in the kettle to below 40°C; the operation of potassium dihydrogen phosphate, mannitol and deionized water 6% is the same as above; ammonium dihydrogen phosphate, glucose The operation with 6% deionized water is the same as above; use the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com