Modified clay double-fluid grout and grout-making and grouting process thereof

A technology of double-liquid slurry and clay, which is applied in mine curtain grouting water blocking engineering, modified clay double-liquid slurry and its grouting and grouting technology field, which can solve the problems that the slurry cannot enter effectively, the quality hidden dangers of the curtain grouting project, and the slurry Solve problems such as preparation sensitivity to reduce grouting and ineffective diffusion, reduce ineffective diffusion, and improve grouting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

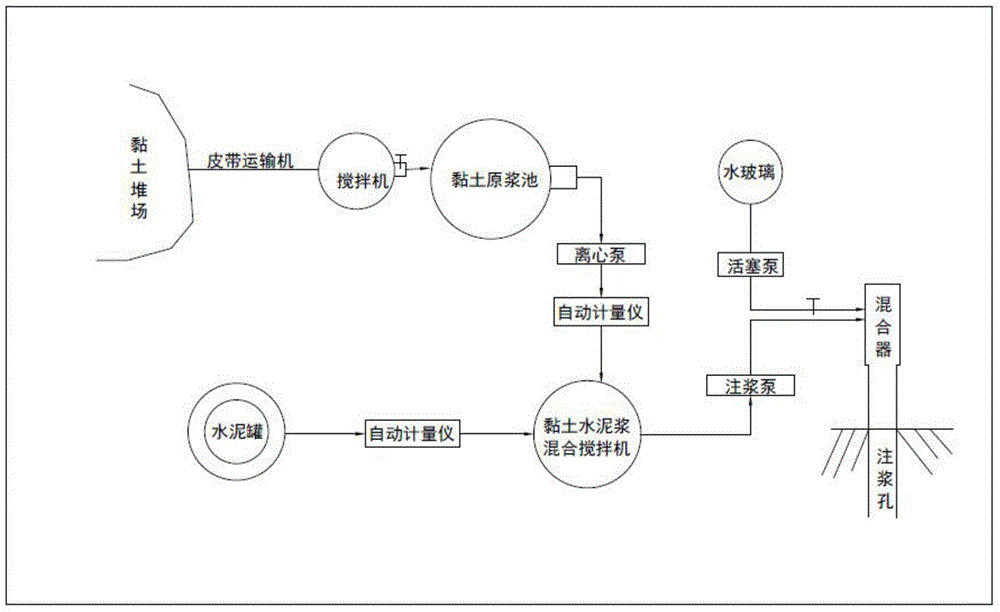

[0036] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

[0037] The invention provides a modified clay two-liquid slurry, which is made by adding water glass with a Baume degree of 39° to 42° to the modified clay slurry;

[0038] The modified clay slurry is composed of the following components in parts by weight:

[0039] Cement: 1

[0040] Clay: 1

[0041] Water: 2

[0042] The volume of the added water glass is 10% to 40% of the volume of the modified clay slurry;

[0043] Or, the modified clay slurry is composed of the following components in parts by weight:

[0044] Cement: 1

[0045] Clay: 1

[0046] Water: 1.6

[0047] The volume of the added water glass is 10%-30% of the volume of the modified clay slurry. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com