Preparation method of burn-free tourmaline biological ceramsite and application thereof in decolouration of dye wastewater

A technology of biological ceramsite and tourmaline, applied in the direction of solid waste management, climate sustainability, sustainable waste treatment, etc., can solve the problem of acid dissolution rate, unsatisfactory physical and chemical properties of bulk density, failure to find decolorizing agent, and poor effect Good and other problems, to achieve the effect of good decolorization effect, moderate strength, low acid dissolution rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

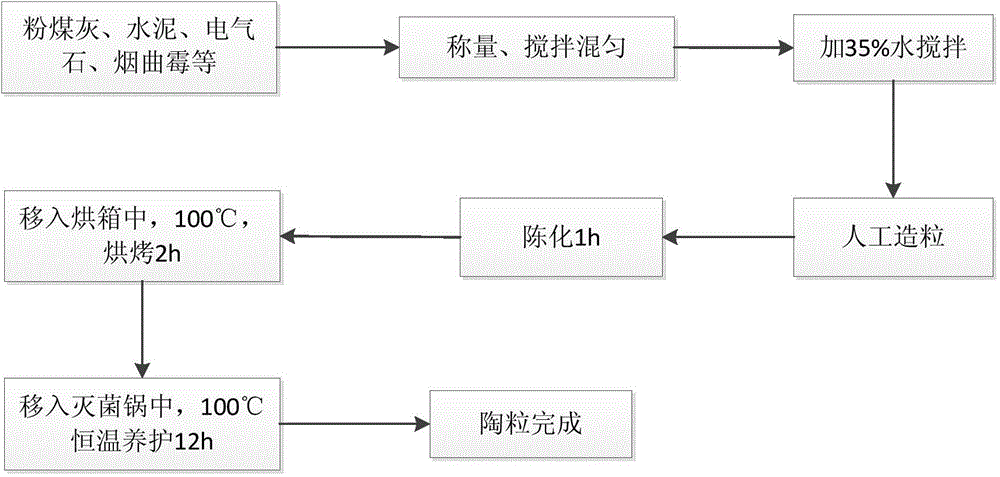

[0032] A kind of non-burning tourmaline biological ceramsite, it is prepared according to the following steps (flow chart sees figure 1 ):

[0033] (1) Weigh each component according to the formula: by mass percentage, 40% of fly ash, 15% of cement, 15% of lime powder, 15% of sodium bicarbonate, 1.5% of gypsum, 5% of water glass, 1% of Aspergillus fumigatus , tourmaline balance;

[0034] (2) Granulation: mix each component uniformly to become a mixture, add water to the mixture, the add-on of water is 35% of the quality of the mixture, stir evenly, granulate in a granulator, and obtain a particle diameter of 3 ~ 6mm spherical ceramsite raw material;

[0035] (3) Aging, drying, and constant temperature steaming of the ceramsite raw meal, that is, placing the ceramsite raw meal at room temperature for 1 hour, then moving it into an oven, drying it at 100°C for 2 hours, and finally moving it into a pressure steam sterilizer to Curing at a constant temperature of 100°C for 12 h...

Embodiment 2

[0038] A kind of unfired tourmaline biological ceramsite, it is prepared according to the following steps:

[0039] (1) Weigh each component according to the formula: by mass percentage, fly ash 46.5%, cement 12%, lime powder 12%, sodium bicarbonate 12%, gypsum 1%, water glass 7%, Aspergillus fumigatus 0.5% , tourmaline balance;

[0040] (2) Granulation: mix each component uniformly to become a mixture, add water to the mixture, the addition of water is 30% of the mixture quality, stir evenly, granulate in a granulator, and obtain a particle diameter of 3 ~ 6mm spherical ceramsite raw material;

[0041] (3) Aging, drying, and constant temperature steaming of the ceramsite raw meal, that is, placing the ceramsite raw meal at room temperature for 2 hours, then moving it into an oven, drying it at 100°C for 1.5 hours, and finally moving it into a pressure steam sterilizer Curing at a constant temperature of 100°C for 10 hours to prepare non-fired tourmaline bio-ceramsite.

[0...

Embodiment 3

[0044] A kind of unfired tourmaline biological ceramsite, it is prepared according to the following steps:

[0045] (1) Weigh each component according to the formula: by mass percentage, fly ash 37.5%, cement 17%, lime powder 17%, sodium bicarbonate 17%, gypsum 2%, water glass 3%, Aspergillus fumigatus 2% , tourmaline balance;

[0046] (2) Granulation: mix each component uniformly to become a mixture, add water to the mixture, the addition of water is 40% of the quality of the mixture, stir evenly, granulate in a granulator, and obtain a particle diameter of 3 ~ 8mm spherical ceramsite raw materials;

[0047] (3) Aging, drying, and constant temperature steaming of the ceramsite raw meal, that is, placing the ceramsite raw meal at room temperature for 1 hour, then moving it into an oven, drying it at 100°C for 3 hours, and finally moving it into a pressure steam sterilizer to Curing at a constant temperature of 100°C for 14 hours to obtain non-fired tourmaline bio-ceramsite. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com