Amino acid anionic-cationic surfactant based composite foaming agent

A surfactant and amino acid technology, applied in the field of amino acid anionic-cationic surfactant composite foaming agents, can solve the problems of reduced foaming force, complicated preparation process, and many reagent components, and achieves large foam volume, The effect of improving interaction and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

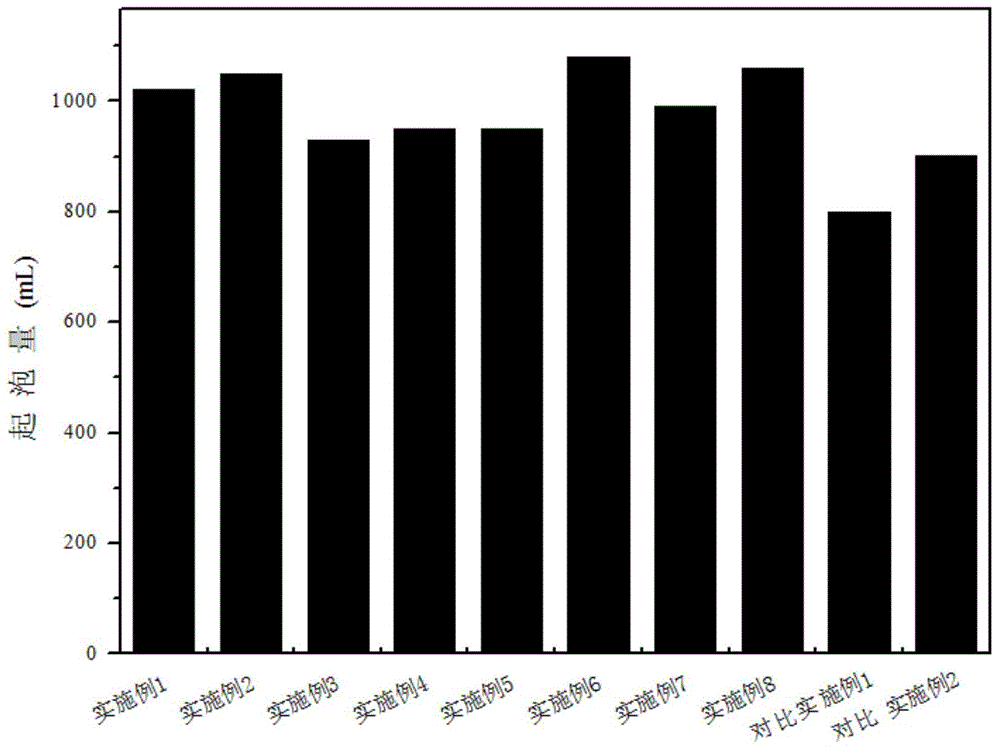

Examples

Embodiment 1

[0017] Mix 0.33g sodium lauryl glycinate and 0.67g cetyltrimethylammonium bromide evenly to obtain an anion-cation surfactant composite foaming agent.

Embodiment 2

[0019] Mix 0.25g sodium laurylglycinate and 0.75g cetyltrimethylammonium bromide evenly to obtain an amino acid anion-cation surfactant composite foaming agent.

Embodiment 3

[0021] 0.20 g of sodium lauryl glycinate and 0.80 g of cetyltrimethylammonium bromide were uniformly mixed to obtain an amino acid anion-cation surfactant composite foaming agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com