Steel and iron slag micro-powder and production method thereof

A production method and technology of iron and steel slag, which is applied in the field of steel slag composite micropowder and its production, can solve the problems of large fluctuations in tailing slag composition and increase the difficulty of utilization, and achieve the effect of high value and high activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

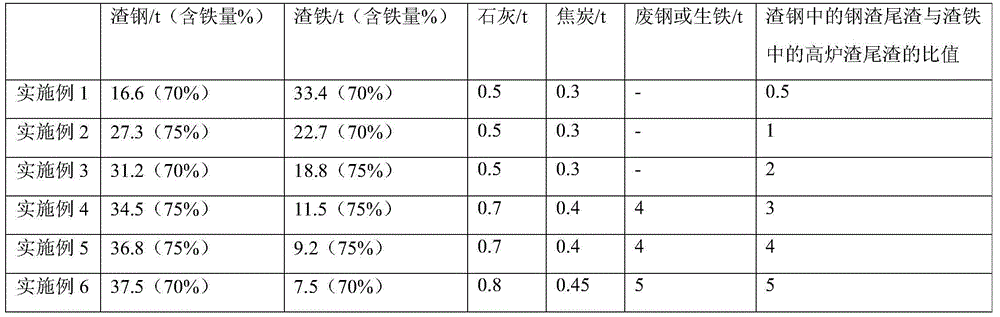

[0029] A steel mill uses the ratio in Table 1 for batching, and each furnace uses the following raw materials for production.

[0030] Table 1 raw material ingredient list

[0031]

[0032] The tailing slag produced after the smelting of steel slag and iron slag was subjected to water quenching treatment, and after iron removal, it was ground with a ball mill under the same conditions.

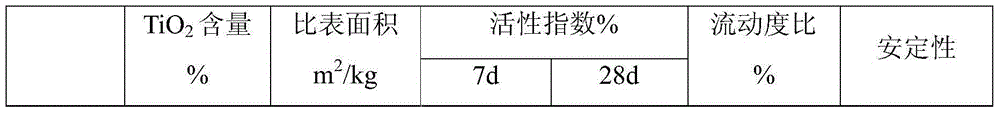

[0033] Table 2 Properties of iron and steel slag micropowder

[0034]

[0035]

[0036] As can be seen from the above table 2, the iron and steel slag micropowder prepared by the present invention has higher activity index and fluidity ratio, and the density, chloride ion content, sulfur trioxide content and ignition loss of the obtained iron and steel slag micropowder of the present invention And other indicators all meet the technical requirements of GB / T28293-2012 "Steel Slag Powder" and meet the production needs.

[0037] In summary, the method of the present invention not only ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com