High-density suspended filler and preparation method thereof

A suspended filler and high-density technology, applied in chemical instruments and methods, water/sludge/sewage treatment, biological water/sewage treatment, etc., can solve problems such as reducing service life, achieve high service life and good sewage treatment capacity , the effect of low comprehensive economic cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

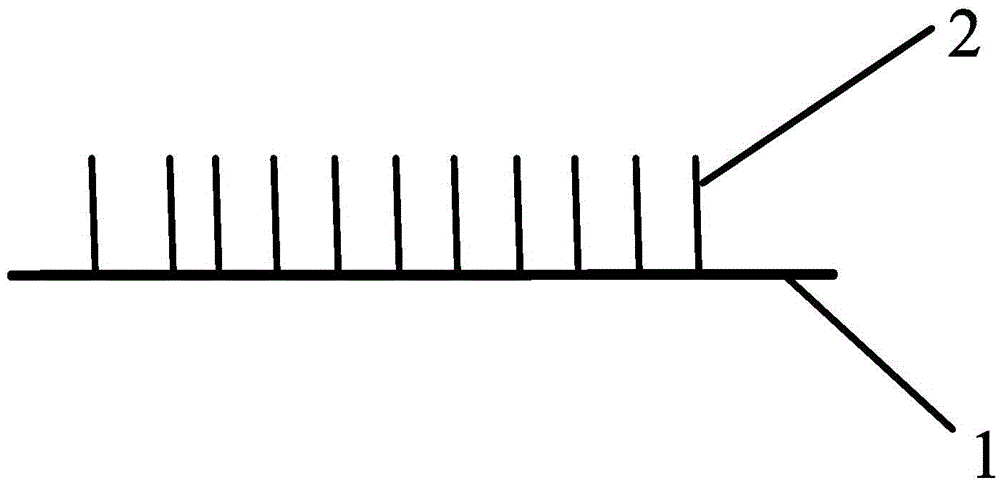

Image

Examples

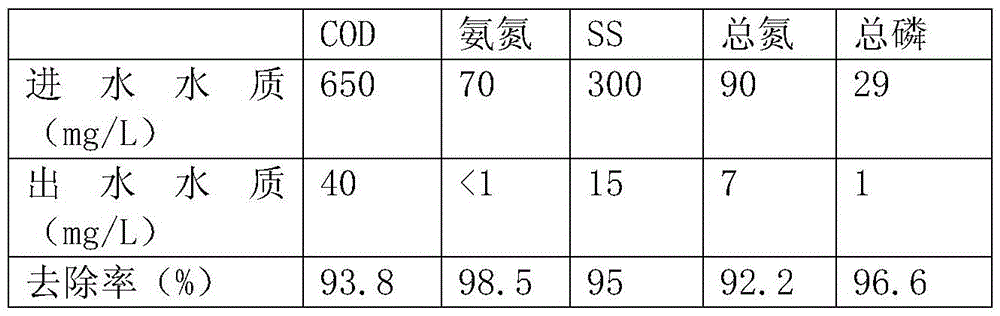

Embodiment 1

[0041] Immerse the vinyl hollow fiber purchased in the market into a water-based non-isocyanate polyurethane material solution, and complete the surface modification through processes such as soaking, throwing and drying. The high-density polyethylene particle raw material is uniformly mixed with nano-calcium carbonate filler, antioxidant 1010, antioxidant 168, etc., and then enters the screw extruder for mixing and extrusion. The screw extrusion temperature is 155-190°C (respectively 160, 175, 177, 180°C), and then the mold is shaped, cooled and cut to the required length to obtain granular honeycomb fillers. The granular honeycomb fillers made of high-density polyethylene are soaked in water-based non-isocyanate polyurethane adhesives. Finally, the surface of the electrostatic flocking equipment is planted with modified hollow fibers, and after later drying and removal of excess fluff, the final filler is obtained.

[0042] The prepared biological filler was used in a munici...

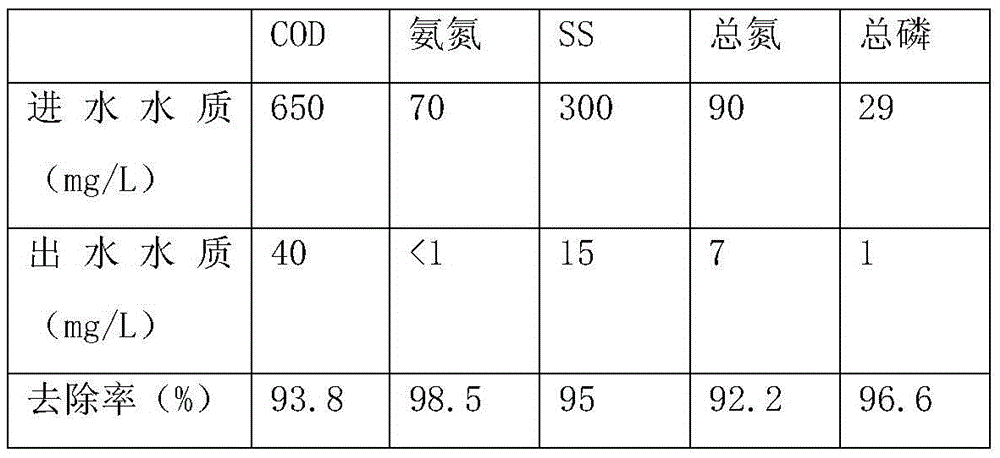

Embodiment 2

[0045] Immerse the vinyl hollow fiber purchased in the market into a water-based non-isocyanate polyurethane material solution, and complete the surface modification through processes such as soaking, throwing and drying.

[0046] The high-density polyethylene particle raw material is uniformly mixed with nano-calcium carbonate filler, antioxidant 1010, antioxidant 168, etc., and then enters the screw extruder for mixed extrusion. After the mold is shaped, it enters the surface of the electrostatic flocking equipment to plant the modified hollow fiber, and after cooling in the later stage, the excess fluff is removed to obtain the final filler.

[0047] The prepared bio-filler was used in a municipal sewage treatment plant in Beijing to improve the standard, and the start-up time of 15-20 ℃ film hanging in autumn was shortened to about 11 days, which met the requirements of nitrogen and phosphorus removal. The load capacity is greatly improved.

[0048]

[0049] The surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com