Haydite sand packaging equipment

A kind of packaging equipment and ceramsite sand technology, applied in the direction of packaging, etc., can solve the problems of failure, plastic lining falling into the packaging bag, plastic lining cannot be fixed, etc., to improve packaging efficiency, standardize operating procedures, reduce The effect of manual input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below in conjunction with specific examples, but not as a limitation of the present invention.

[0033] The problem to be solved by the embodiments of the present invention is that the plastic inner lining of the existing simple packaging rack cannot be fixed, and it is easy to cause the plastic inner lining to fall into the inside of the packaging bag, resulting in packaging failure.

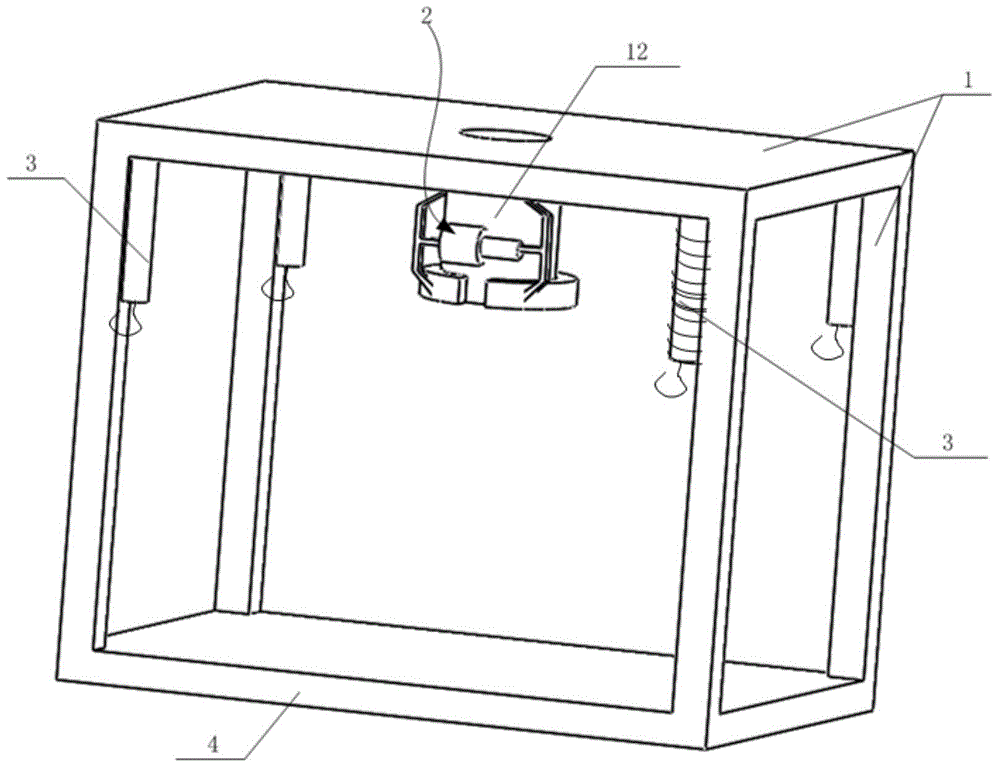

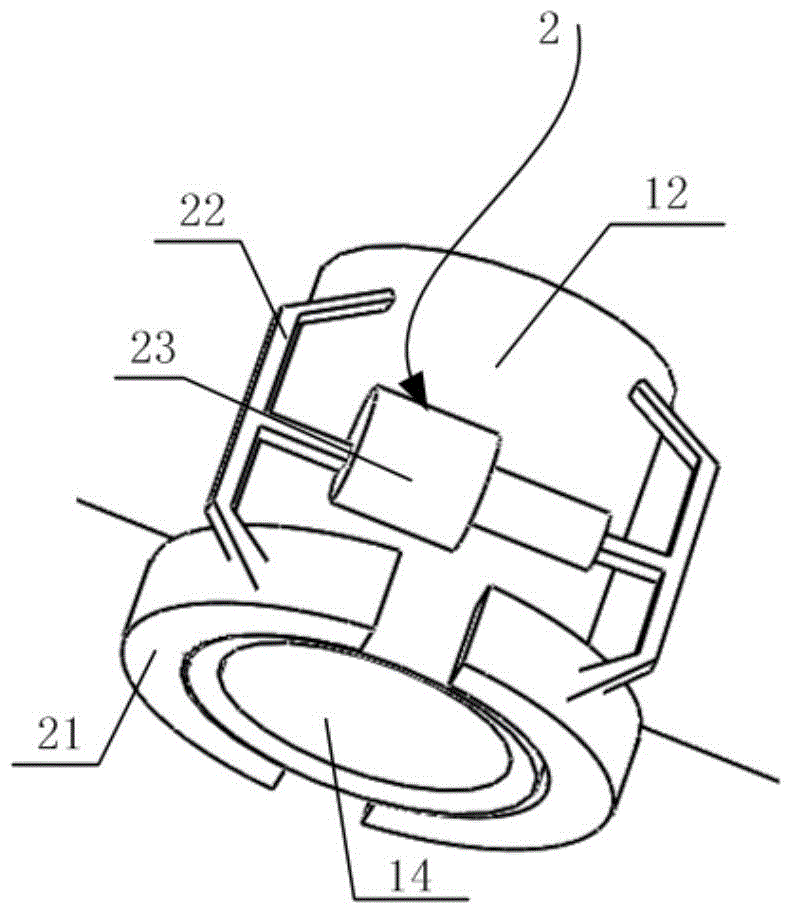

[0034] Such as figure 1 with figure 2 As shown, a kind of ceramsite sand packaging equipment is provided for the embodiment of the present invention, which is used to fill the packaging bag with inner lining. The device includes:

[0035] The packing rack 1 includes a table top, legs are fixedly connected to the corners of the table top, and a feeding pipeline 12 is arranged in the middle of the table top;

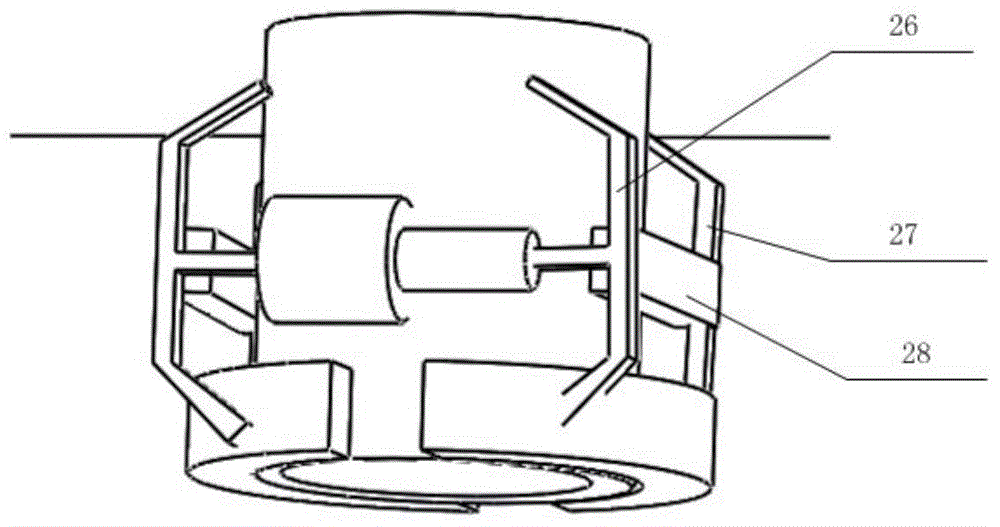

[0036] The lining locking device 2 includes: a first arm 22, one end of which is hinged on the feed pipe 12; a first clam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com