Acetylene method vinyl acetate catalyst and preparation method thereof

A vinyl acetate and catalyst technology, applied in the field of acetylene gas phase method vinyl acetate catalyst, can solve problems such as low catalyst activity, and achieve the effect of improving space-time yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

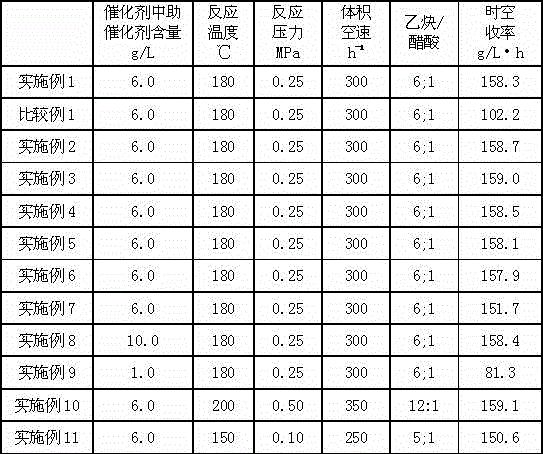

Examples

Embodiment 1

[0021] 1. Catalyst preparation method

[0022] (a) Carrier preparation: measure 1L with a diameter of 3 mm, a length of 2 cm, and a pore volume of 0.8 cm 3 / g, the specific surface area is 1200 cm 2 / g of coal-based cylindrical activated carbon is placed in a microwave-heated quartz tube, and under the protection of He protective gas, microwave treatment is carried out for 30min with a power of 500W and a frequency of 2450MHZ to obtain the carrier.

[0023] (b) Impregnation: impregnate the above 1L carrier with 610ml of impregnation solution. Zn(OAc) in the immersion solution 2 The content is 120 g, the content of potassium acetate is 6.0 g, and the solvent in the impregnation solution is a mixed solvent of acetic acid and water (70 wt% acetic acid and 30 wt% water).

[0024] (c) Drying: drying at 100°C to obtain the catalyst.

[0025] 2. Catalyst evaluation

[0026] The catalysts synthesized by the above method were evaluated in a laboratory microreactor. The evalua...

Embodiment 2

[0037] 1. Catalyst preparation method

[0038] (a) Carrier preparation: measure 1L with a diameter of 3 mm, a length of 2 cm, and a pore volume of 0.8 cm 3 / g, the specific surface area is 1200 cm 2 / g of coal-based cylindrical activated carbon placed in a microwave-heated quartz tube, in H 2 Under the protection of protective gas, microwave treatment was carried out at a power of 500W and a frequency of 2450MHZ for 30min to obtain the carrier.

[0039] (b) Impregnation: impregnate the above 1L carrier with 610ml of impregnation solution. Zn(OAc) in the immersion solution 2 The content is 120 g, the content of potassium acetate is 6.0 g, and the solvent in the impregnation solution is a mixed solvent of acetic acid and water (70 wt% acetic acid and 30 wt% water).

[0040] (c) Drying: drying at 100°C to obtain the catalyst.

[0041] 2. Catalyst evaluation

[0042]The catalysts synthesized by the above method were evaluated in a laboratory microreactor. The evaluation...

Embodiment 3

[0045] 1. Catalyst preparation method

[0046] (a) Carrier preparation: measure 1L with a diameter of 3 mm, a length of 2 cm, and a pore volume of 0.8 cm 3 / g, the specific surface area is 1200 cm 2 / g of cylindrical coconut shell activated carbon is placed in a microwave-heated quartz tube, under the protection of Ar protective gas, with a power of 500W, a frequency of 2450MHZ is used for microwave treatment for 30min to obtain the carrier.

[0047] (b) Impregnation: impregnate the above 1L carrier with 610ml of impregnation solution. Zn(OAc) in the immersion solution 2 The content is 120 g, the content of potassium acetate is 6.0 g, and the solvent in the impregnation solution is a mixed solvent of acetic acid and water (70 wt% acetic acid and 30 wt% water).

[0048] (c) Drying: drying at 100°C to obtain the catalyst.

[0049] 2. Catalyst evaluation

[0050] The catalysts synthesized by the above method were evaluated in a laboratory microreactor. The evaluation co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com