Method for preparing adsorbent by using bottom mud of Dian Lake and application thereof

A technology of adsorbent and bottom mud, which is applied in the field of preparation of new heavy metal adsorbents, and achieves the effects of simple operating conditions, high yield of finished products, and increased adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

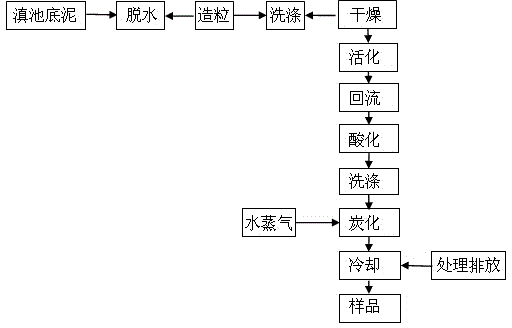

[0022] A kind of method of preparing adsorbent with the bottom mud of Dianchi Lake described in this embodiment (such as figure 1 shown), specifically include the following steps:

[0023] (1) Dehydrate the bottom mud of Dianchi Lake until the water content is 33%, enter the granulation device to make bottom mud granules with a diameter of 2 mm, soak in distilled water for 3 hours and wash, wash repeatedly 3 times, and then put it in an oven for drying ;

[0024] (2) According to the ratio of 5g / 100ml, add the bottom mud of Dianchi Lake into the glutaraldehyde solution with a mass fraction of 1% and soak for 10h, stir with a magnetic stirrer for 15min every 1.5h, and filter;

[0025] (3) Add 10ml of polydimethyldiallylammonium chloride solution to the sludge obtained in step (2) per 1g of sludge, soak After 6 hours, place it in a water bath at 60°C and heat it to reflux for 100 minutes. After pouring off the supernatant, acidify it with 0.1mol / L hydrochloric acid for 1.5 hou...

Embodiment 2

[0031] A method for preparing an adsorbent from the bottom mud of Dianchi Lake described in this embodiment specifically includes the following steps:

[0032] (1) Dehydrate the bottom mud of Dianchi Lake until the water content is 35%, enter the granulation device to make bottom mud particles with a diameter of 2.5m, soak in distilled water for 2.5h and wash, wash repeatedly 4 times, and then put it into the oven drying;

[0033] (2) According to the ratio of 10g / 100ml, add the bottom mud of Dianchi Lake to the glutaraldehyde solution with a mass fraction of 2%, soak for 11 hours, stir with a magnetic stirrer for 12 minutes every 1.8 hours, and filter;

[0034] (3) According to the ratio of adding 15ml polydimethyldiallylammonium chloride solution to the sludge obtained in step (2) per 1g, add polydimethyldiallylammonium chloride solution to the sludge, soak After 7 hours, place it in a water bath at 50°C and heat it under reflux for 110 minutes. After pouring off the supernat...

Embodiment 3

[0040] A method for preparing an adsorbent from the bottom mud of Dianchi Lake described in this embodiment specifically includes the following steps:

[0041] (1) Dehydrate the bottom mud of Dianchi Lake until the water content is 37%, enter the granulation device to make bottom mud granules with a diameter of 3 mm, soak in distilled water for 2 hours and wash, wash repeatedly 5 times, and then put it in an oven for drying ;

[0042] (2) According to the ratio of 15g / 100ml, add the bottom mud of Dianchi Lake to the glutaraldehyde solution with a mass fraction of 3%, soak for 12 hours, stir with a magnetic stirrer for 10 minutes every 2 hours, and filter;

[0043] (3) Add 20ml of polydimethyldiallyl ammonium chloride solution to the sludge at the ratio of 20ml of polydimethyldiallylammonium chloride solution per 1g of the sludge obtained in step (2), soak After 8 hours, place it in a water bath at 70°C and heat it to reflux for 120 minutes. After pouring off the supernatant, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com