Stirred tank reactor for cutting fluid

A technology for stirring reaction kettle and cutting fluid, applied in the field of chemical machinery and equipment, can solve the problems of weak liquid stirring ability, uniform mixing of unfavorable reactants, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

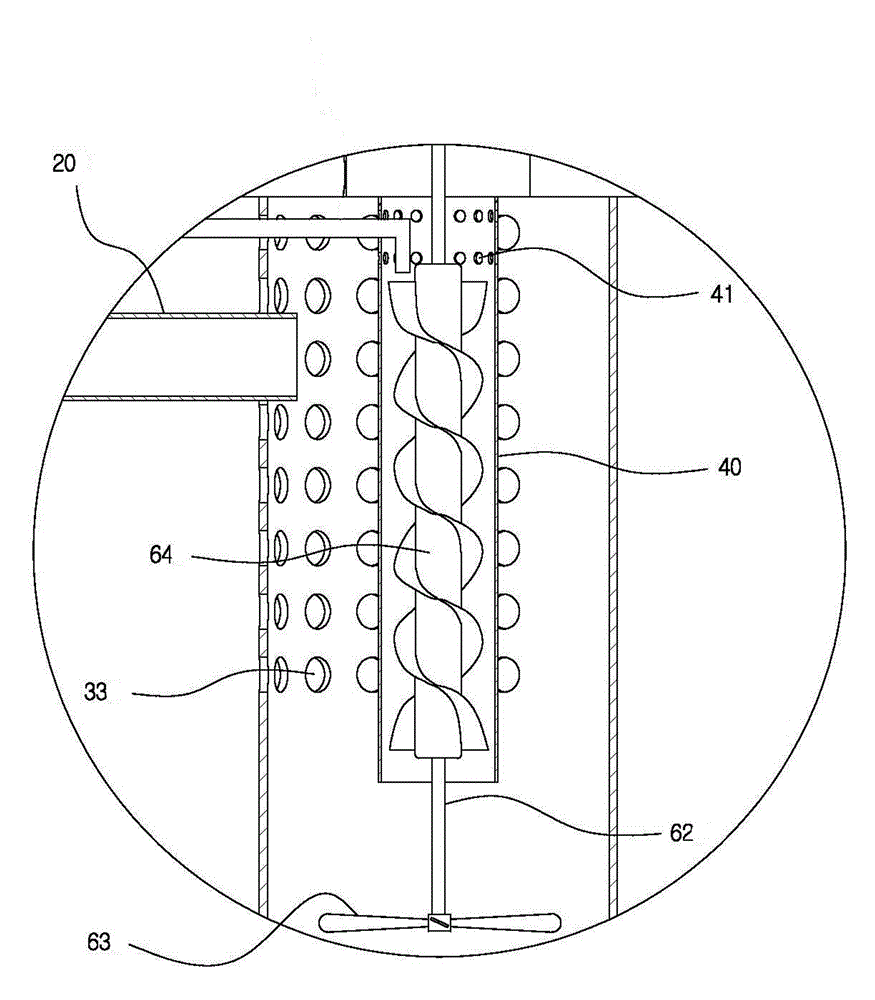

[0024] like figure 1 As shown, the stirring reactor for cutting fluid of the present invention includes a reactor body 10, an upper cover 60 arranged on the reactor body 10 and a motor 61 arranged on the upper cover 60, and the output of the motor 61 is The shaft passes through the upper cover 60 and intervenes in the kettle body 10 .

[0025] The stirring reaction kettle for cutting fluid of the present invention includes a stirring paddle 63 arranged in the kettle body 10, the stirring paddle 63 is connected to the output shaft of the motor 61, and a drainage tube 31, and the upper cylinder port of the drainage tube 31 is connected to On the inner wall of the kettle body 10 below the upper cover 60 , a stirring paddle 63 is arranged in the drainage tube 31 .

[0026] Under the premise of meeting the strength and rigidity requirements, the drainage tube 31 is made of light materials as much as possible to achieve the purpose of reducing the weight. In this embodiment, thick ...

Embodiment 2

[0032] like figure 2 As shown, the difference between this embodiment and Embodiment 1 is that this embodiment also includes a drainage tube 40 disposed in the drainage tube 31, the connecting shaft 62 is disposed in the drainage tube 40, and on the connecting shaft 62 An auger blade 64 is provided, the upper and lower openings of the drainage tube 40 are fixed, and the upper opening is fixed on the inner wall of the kettle body 10, the drainage tube 51 penetrates into the drainage tube 40, and the nozzle of the drainage tube 51 Above the auger blade 64, a small drainage hole 41 is provided on the side wall of the drainage tube 40 above the mouth of the feed tube 20 at a height position, where the small drainage hole 41 is twelve times the diameter of the drainage tube 40. between one-tenth and one-tenth.

[0033] like figure 1 , 2 As shown, there is no drainage hole 33 on the side wall of the drainage tube 31 facing the nozzle of the feed pipe, so as to prevent the raw ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com