Composite filter membrane and processing device and method for the composite filter membrane

A processing method and filter membrane technology, which are applied in the field of composite filter membranes and processing devices of the composite filter membranes, can solve the problems of single filtration precision of composite filter materials, easy clogging of adhesives, and small amount of pollutants, and reduce the use of The effect of cost, accurate and uniform control and large amount of pollutants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

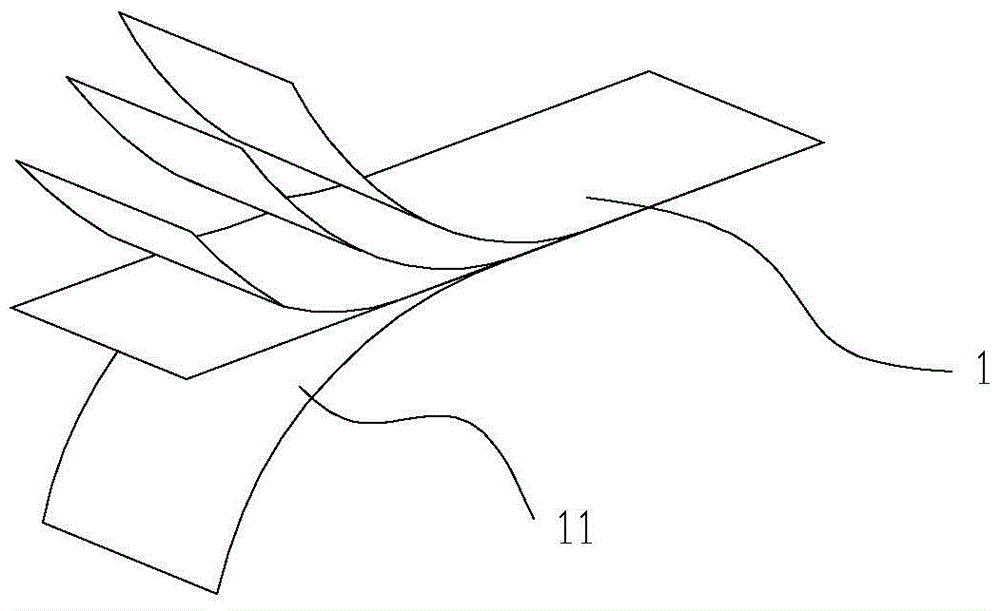

[0025] Embodiment 1: a kind of composite filter membrane of present embodiment 1 is used for the filtration of fluid, and the filtration accuracy of composite filter membrane is 10 μ m, as figure 1 As shown, the composite filter membrane 1 is formed by laminating and hot-pressing five layers of imitation viscose nonwoven fabric 11 with different precision. The lower layer is 50 μm, 40 μm, 20 μm, 20 μm, and 10 μm in sequence, and is hot-pressed by the processing device to form a composite filter membrane with gradient depth filtration.

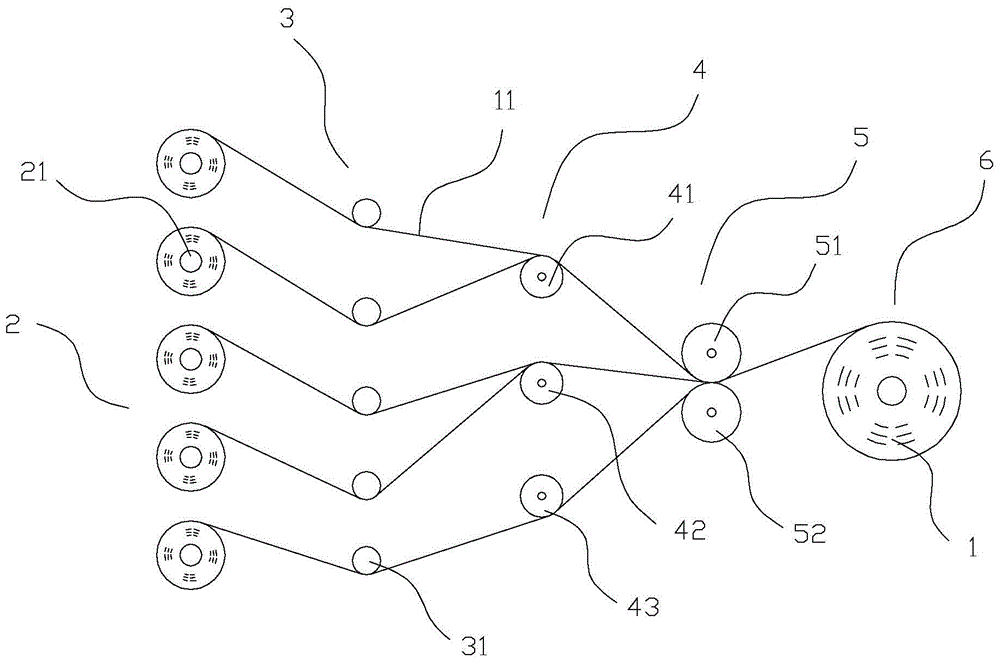

[0026] The processing device of the above composite filter membrane, such as figure 2 As shown, it includes the unwinding roller group 2, the correction roller group 3, the heating roller group 4, the composite pressing roller group 5, the winding roller group 6 and the electric control device for controlling the corresponding roller group arranged in sequence, wherein the unwinding roller group consists of It is composed of five unwinding gu...

Embodiment 2

[0033] Embodiment 2: A kind of composite filter membrane of this embodiment 2, is used for the filtration of fluid, and the filtration precision of composite filter membrane is 10 μ m, is formed by laminating and hot-pressing imitation viscose non-woven fabric of five layers of different precision, imitation viscose The non-woven fabric is made of ES fibers with a two-component sheath-core structure, and is hot-pressed by a processing device to form a composite filter membrane with gradient depth filtration.

[0034] The processing device for the composite filter membrane as above includes the unwinding roller group, the deviation correcting roller group, the heating roller group, the composite pressing roller group, the winding roller group and the electric control device for controlling the corresponding roller group arranged in sequence. The composite pressing roller group consists of upper and lower Composed of two pressure rollers, the surface of the upper pressure roller ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com