Diesel engine filter

A filter and diesel engine technology, which is applied in the direction of machines/engines, mechanical equipment, engine components, etc., can solve the problems of inability to filter impurities, incomplete filtration of water, and poor protection of diesel engines, so as to improve water removal capacity and filter effect. , the effect of protecting the diesel engine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

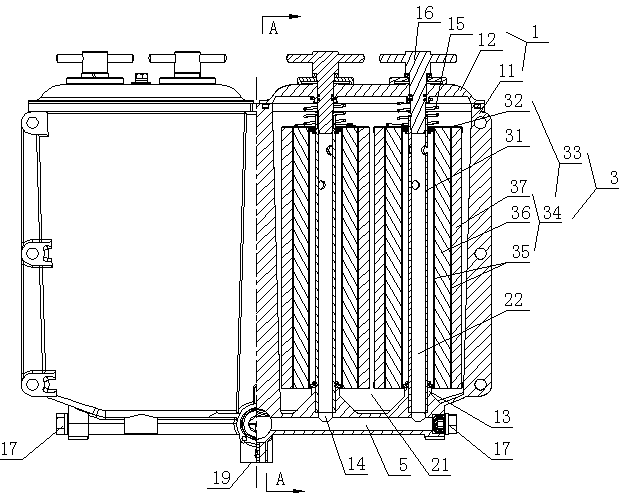

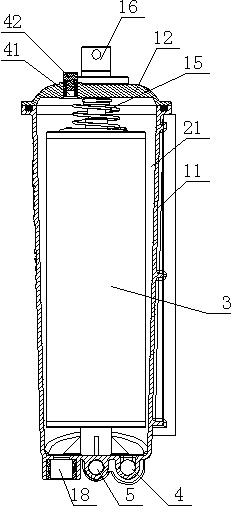

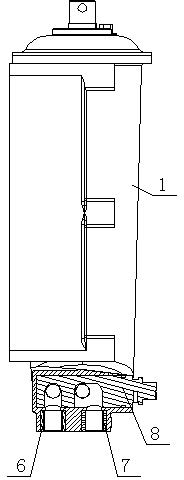

[0021] Such as figure 1 The diesel engine filter shown includes a filter body 1, and the filter body 1 has at least one inner cavity that gradually becomes larger from bottom to top, and at least one valve connected to the filter body 1 is arranged in the inner cavity A filter cartridge 3, the filter in the figure is provided with two inner cavities arranged side by side, each inner cavity is equipped with a filter cartridge 3, the advantage of the inner cavity that gradually becomes larger from top to bottom is to ensure that the filter While maintaining the strength of the body, it can effectively ensure the filtration capacity and filtration accuracy. The space between the outer surface of the filter cartridge 3 and the inner cavity wall is the oil inlet chamber 21; Shaft 31, the outer side of the hollow shaft 31 is equipped with a filter element 33, the inner cavity of the hollow shaft 31 is the oil outlet chamber 22, and the lower part of the filter body 1 is provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com