Pressure-coupled chromatography column fluid distributor

A technology of fluid distributor and chromatographic column, which is applied in the field of chromatographic column, can solve the problems of affecting chromatographic efficiency, large pressure loss, large length difference, etc., achieve uniform flow distribution, improve chromatographic efficiency, and be easy to implement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following examples are further explanations and illustrations of the present invention, and do not constitute any limitation to the present invention.

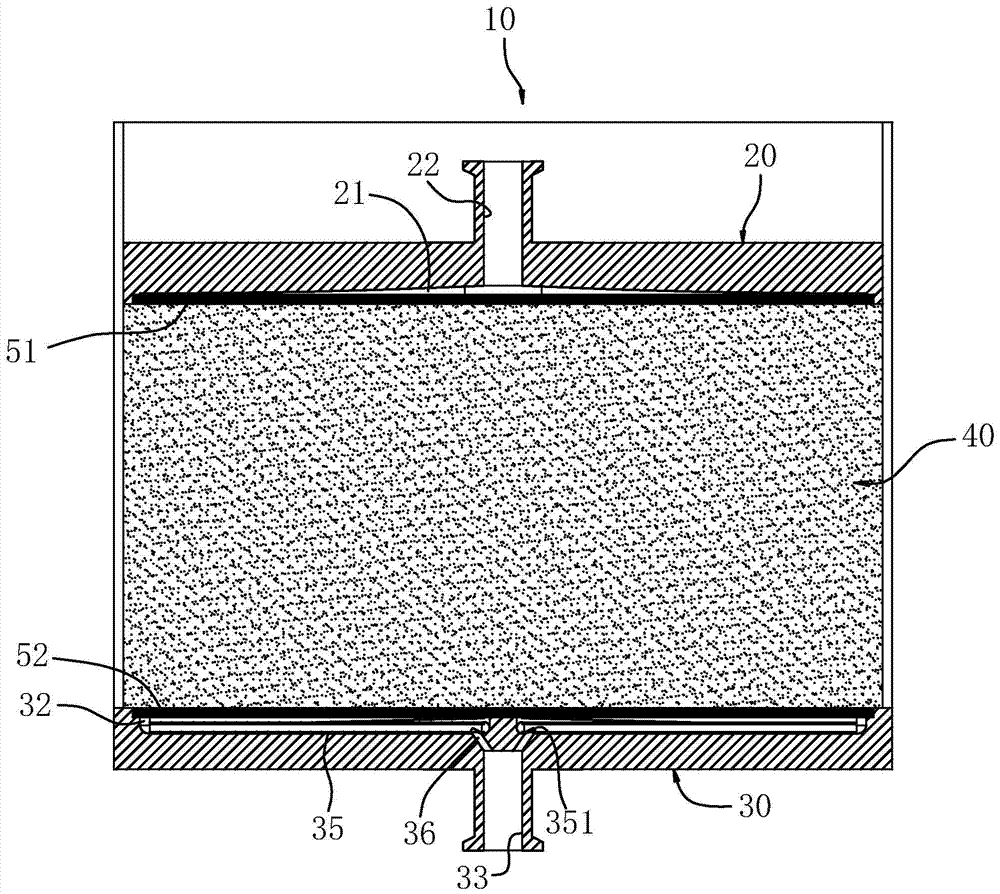

[0019] refer to figure 1 , the pressure-coupled chromatography column fluid distributor of the present invention includes a first distribution plate 20 and a second distribution plate 30 . The first distribution plate 20 and the second distribution plate 30 are respectively arranged at the two ends of the gel 40 in the chromatography column 10. The gel 40 can be a gel known in the art, which is used for different components in the liquid separation.

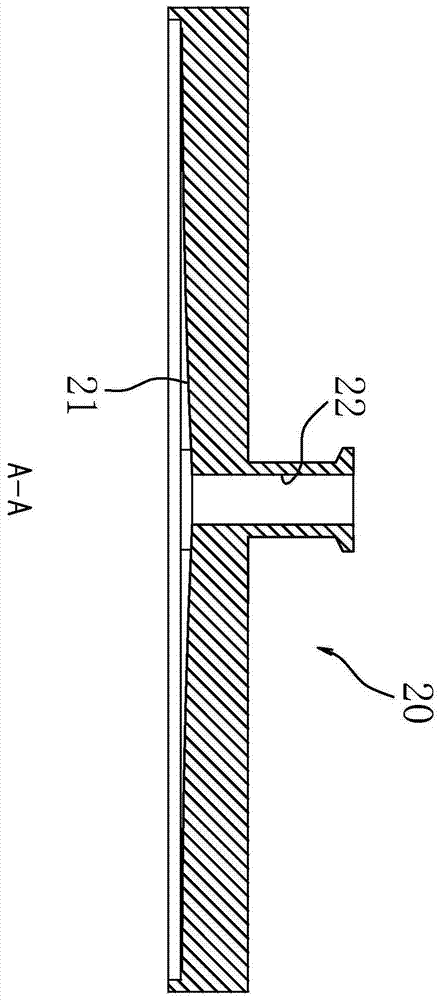

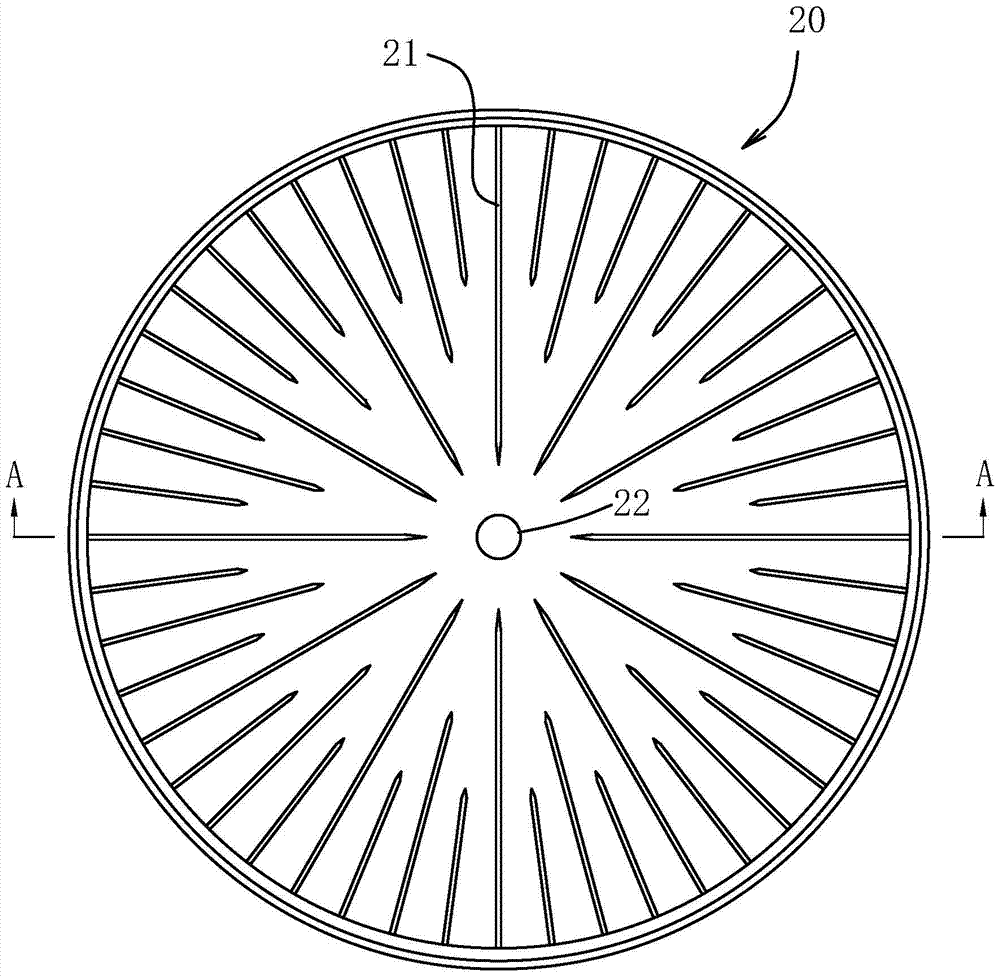

[0020] Such as figure 2 , image 3 As shown, the first distribution plate 20 is a disc-shaped body made of polypropylene plastic, and a plurality of radial first fluid grooves 21 are provided on the surface of the side opposite to the gel. In this embodiment, the first A fluid groove 21 is arranged on the lower side of the first distribution plate 20, and a plura...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com