Self-similarity micro-channel heat sink with jet flow structure

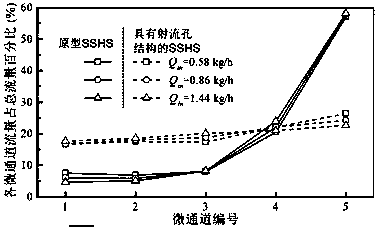

A microchannel and self-similar technology, applied in electrical components, electrical solid devices, circuits, etc., can solve problems such as uneven flow distribution and uneven heat transfer restrictions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The main content of the present invention is further illustrated below in conjunction with specific examples, but the content of the present invention is not limited to the following examples.

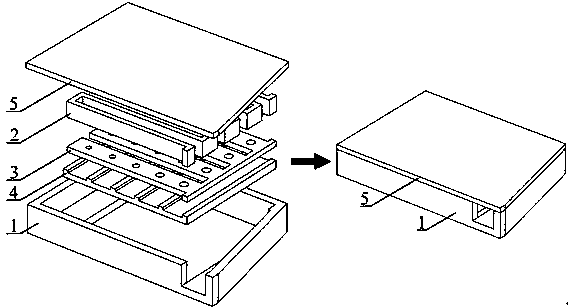

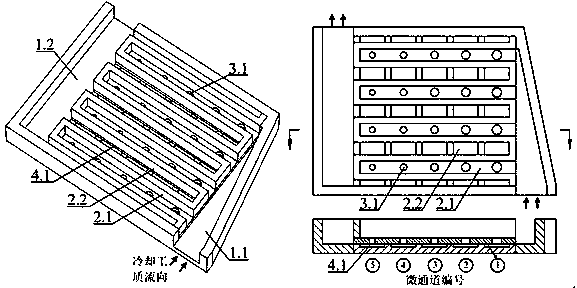

[0018] The invention discloses a self-similar microchannel heat sink with a jet hole structure, which comprises a main inflow and outflow structure (1), a split layer (2), a jet hole plate layer (3), a microchannel layer (4), and top cover (5). The inflow and outflow structure (1) includes a main inflow channel (1.1) and a main outflow channel (1.2). The split layer (2) includes split sub-channels (2.1) and outflow sub-channels (2.3). The jet orifice plate layer (3) is provided with a number of jet holes (3.1), and the opened positions are arranged along the flow direction of the sub-channels (2.1), and the diameter of each jet hole decreases along the flow. The microchannel layer (4) is located below the jet orifice layer (3), and is composed of several microgrooves arranged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com