Method for preparing rice protein powder

A technology for rice protein powder and rice grains, applied in the field of protein powder, can solve the problems of imperfect extraction method, low protein content, limited application, etc., and achieve the effects of stable, safe and reliable process, stable product quality and good water solubility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

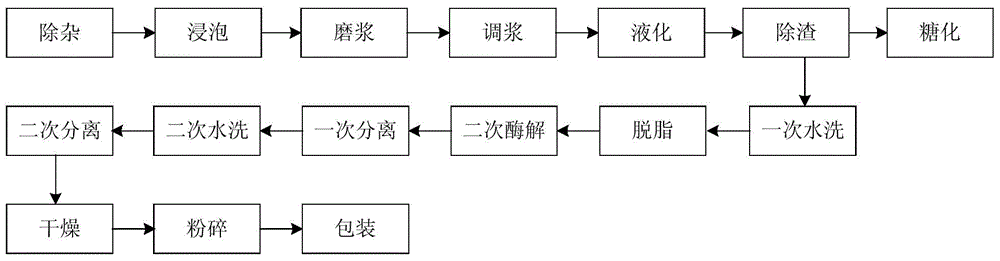

[0037] like figure 1 As shown, the present invention provides a preparation method of rice protein powder, comprising the following steps:

[0038] Throwing rice: The broken rice that has passed the inspection is injected into the rice soaking tank, and the injection volume is five tons. In the process of throwing rice, it is also necessary to remove impurities from the broken rice, including the following steps:

[0039] Stone removal: The light chaff shell and heavy gravel in the material are separated by a grading stone remover;

[0040] Color sorting: remove all white, immature and heterochromatic grains through the color sorter;

[0041] Iron removal: use a pipe iron remover or a magnetic rod to remove the fine iron filings in the material;

[0042] Sand removal: Use a sand remover to remove the fine sand particles in the slurry.

[0043] Soaking: Fill the rice soaking pot with water and soak for at least 120min;

[0044] Refining: The soaked broken rice is pulverize...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com