Bidirectional silicon controlled rectifier adjusting type liquid resistance starter

A liquid resistance and starter technology, applied in the electrical field, can solve the problems of large noise, large space, and bulky, etc., and achieve the effects of no noise, simple operation, and reduced production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

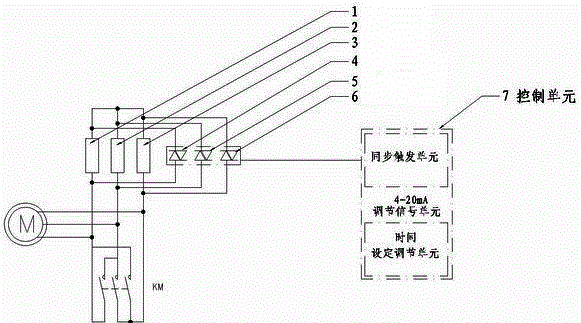

[0008] Such as figure 1 As shown, the liquid resistance A1, liquid resistance B2, and liquid resistance C3 of the motor are connected in parallel with bidirectional thyristor A4, bidirectional thyristor B5, bidirectional thyristor C6, bidirectional thyristor A4, bidirectional thyristor B5, bidirectional thyristor The conduction angle of the thyristor C6 is controlled by the control unit 7; the control unit 7 is composed of a time setting adjustment unit, an adjustment signal unit, and a synchronous trigger unit. Long, output a 4-20mA adjustment signal after calculation, the trigger unit sends a real-time trigger command according to the size of the adjustment signal and when the synchronization signal is valid, adjust the conduction of bidirectional thyristor A4, bidirectional thyristor B5, and bidirectional thyristor C6 Angle from small to large, to full conduction, so as to complete the adjustment process of the equivalent resistance from large to small, to zero.

[0009] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com