Technique and equipment for preparing high-temperature super-conduction strip materials by virtue of laser chemical vapor deposition method

A technology of chemical vapor deposition and high-temperature superconducting strips, which is applied in the usage of superconducting elements, gaseous chemical plating, superconducting devices, etc., can solve the problems of slow deposition speed, reduction of activation energy of reaction between raw material molecules, and low production efficiency And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

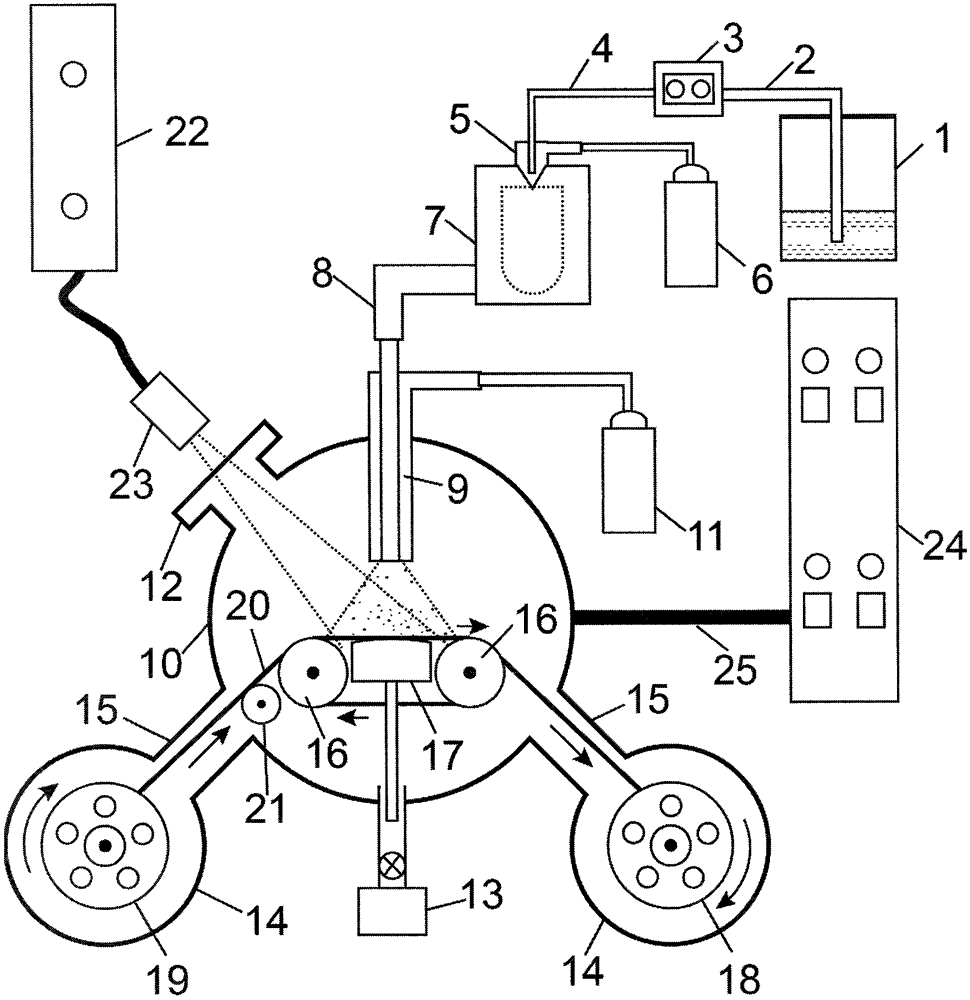

[0013] When the equipment is running, the main reaction chamber 10, the two secondary reaction chambers 14 and the chamber connecting pipe 15 will reduce the pressure of the chamber to the required value under the action of the vacuum pump 13, providing necessary conditions for the preparation of the film.

[0014] The liquid raw material in the liquid raw material tank 1 is drawn by the liquid raw material supply part 3 through the liquid raw material extraction pipe 2, and is continuously and stably sent to the pressure chamber 5 via the liquid raw material delivery pipe 4. The gas in the carrier gas storage tank 6 generates pressure in the pressure chamber 5 and quickly presses out the liquid raw material that has been pressured into the pressure chamber 5, and the liquid raw material is thus atomized into small droplets. When the atomized small droplets are sprayed to the wall of the spray atomization-multi-eutectoid volatilization cavity 7, the solvent in the small droplets v...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com