Abrasion-resistant polytetrafluoroethylene and aramid fiber reinforced-modified PA66 material and preparation method thereof

A technology of polytetrafluoroethylene and aramid fiber, applied in the field of polytetrafluoroethylene and aramid fiber wear-resistant reinforced modified PA66 material and its preparation, can solve the problems of easy water absorption, affecting dimensional stability and electrical properties, etc. Achieve excellent wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

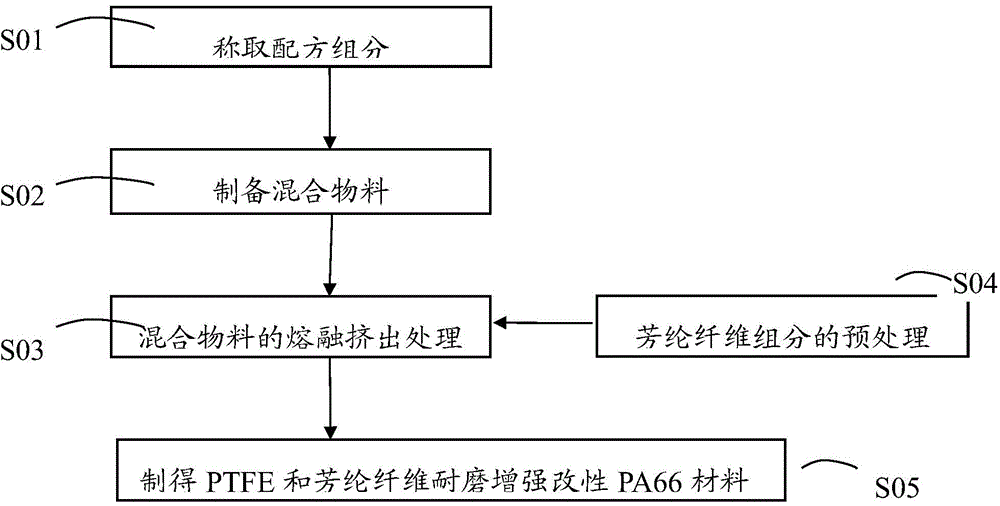

Method used

Image

Examples

Embodiment 1

[0025] A kind of polytetrafluoroethylene and aramid fiber wear-resisting reinforced modified PA66 material of this embodiment, by weight percentage, consist of the following components:

[0026] 74% PA66 resin; 10% aramid fiber; 3% compatibilizer; 5% toughening agent; 1% coupling agent; 5% polytetrafluoroethylene; 2% plastic processing aid.

[0027] Its preparation method is as follows:

[0028] Step 1, weighing each component according to the above-mentioned weight percentage, and carrying out drying treatment on each component taken;

[0029] Step 2. Put the dried PA66 resin, compatibilizer and coupling agent in a high-speed mixer or blender and pre-mix for 3-5 minutes, then add PTFE resin powder, toughener and plastic processing aids to continue Mix for 10-20min;

[0030] Step 3. While performing Step 2, place the aramid chopped fiber roll in the coupling agent for pre-soaking treatment for 3-5 minutes;

[0031] Step 4: Put the mixed material into the hopper of the twin-...

Embodiment 2

[0033] A kind of polytetrafluoroethylene and aramid fiber wear-resisting reinforced modified PA66 material of this embodiment, by weight percentage, consist of the following components:

[0034] 60% PA66 resin; 15% aramid fiber; 4% compatibilizer; 7% toughening agent; 2% coupling agent; 10% polytetrafluoroethylene; 2% plastic processing aid.

[0035] Its preparation method is as follows:

[0036] Step 1, weighing each component according to the above-mentioned weight percentage, and carrying out drying treatment on each component taken;

[0037] Step 2. Put the dried PA66 resin, compatibilizer and coupling agent in a high-speed mixer or blender and pre-mix for 3-5 minutes, then add PTFE resin powder, toughener and plastic processing aids to continue Mix for 10-20min;

[0038] Step 3. While performing Step 2, place the aramid chopped fiber roll in the coupling agent for pre-soaking treatment for 3-5 minutes;

[0039] Step 4: Put the mixed material into the hopper of the twin...

Embodiment 3

[0041] A kind of polytetrafluoroethylene and aramid fiber wear-resisting reinforced modified PA66 material of this embodiment, by weight percentage, consist of the following components:

[0042] 48% PA66 resin; 20% aramid fiber; 5% compatibilizer; 8% toughening agent; 2% coupling agent; 15% polytetrafluoroethylene; 2% plastic processing aid.

[0043] Its preparation method is as follows:

[0044] Step 1, weighing each component according to the above-mentioned weight percentage, and carrying out drying treatment on each component taken;

[0045]Step 2. Put the dried PA66 resin, compatibilizer and coupling agent in a high-speed mixer or blender and pre-mix for 3-5 minutes, then add PTFE resin powder, toughener and plastic processing aids to continue Mix for 10-20min;

[0046] Step 3. While performing Step 2, place the aramid chopped fiber roll in the coupling agent for pre-soaking treatment for 3-5 minutes;

[0047] Step 4: Put the mixed material into the hopper of the twin-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com