High-temperature resistant clay stabilizer and preparation method thereof

A clay stabilizer and high-temperature-resistant technology, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of high-temperature resistance, salt resistance, long-term low-permeability medium and low permeability reservoirs, pore clogging, Poor anti-swelling effect and other problems, to achieve the effect of preventing hydration swelling, good effect, and strong washing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

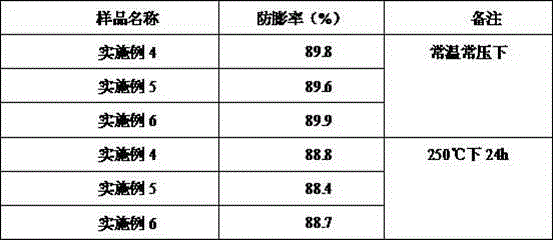

Examples

Embodiment 1

[0035] Dissolve 42g of 2-acrylamido-2-methylpropanesulfonic acid in 58g of water, adjust the pH to about 7 with KOH, and set aside. Add 69.4g of epichlorohydrin to the reactor, control the temperature of the reactor at 20°C, add 56.3g of 40% dimethylamine aqueous solution and 50g of the prepared 2-acrylamido-2-methyl Potassium propanesulfonate solution, then add 13.5g allyltrimethylammonium chloride, 60g water, feed nitrogen into the reactor for 30min and add 1.1g of sodium bisulfite after 3min, add 2.7g of ammonium persulfate after 3min, React at a temperature of 40°C for 2 to 8 hours. During the reaction, detect the molecular weight of the product. When the molecular weight is 4216, add 4.1 g of sodium formate. After the reaction is complete, a clay stabilizer is obtained. The structural formula of the product is as follows after infrared analysis:

[0036]

[0037] In the formula, x:y:z= 5:1:1.

Embodiment 2

[0039] Dissolve 40g of acrylamide butyl sulfonic acid in 60g of water, adjust the pH to about 7 with KOH, and set aside. Add 69.4g epichlorohydrin to the reactor, the reactor temperature is controlled at 20°C, add 56.3g mass fraction of 40% dimethylamine aqueous solution and 50g of the above prepared potassium acrylamide butyl sulfonate solution, and then Add 23.4g mass fraction and be 70% dimethyl diallyl ammonium chloride aqueous solution, 65g water, feed nitrogen into the reactor for 30min, add 1.1g of sodium bisulfite after 3min, add 2.7g of ammonium persulfate after 3min , react at a temperature of 40°C for 2 to 8 hours, and detect the molecular weight of the product during the reaction. When the molecular weight is 4330, add 3.3g of sodium formate. After the reaction is completed, a clay stabilizer is obtained. Its structural formula is as follows through infrared analysis:

[0040]

[0041] In the formula, x:y:z=25:5:6.

Embodiment 3

[0043] Dissolve 22g of vinyl sulfonic acid in 40g of water, adjust the pH to about 7 with KOH, and set aside. Add 34.7g of epichlorohydrin to the reactor, control the temperature of the reactor at 20°C, add 28.2g of dimethylamine aqueous solution with a mass fraction of 40% and 31g of the above prepared potassium vinylsulfonate solution, and then add 31.5 The g mass fraction is 60% diethyldiallyl ammonium chloride aqueous solution, 24 g water, feeds nitrogen into the reactor after 30min and adds 0.5g of sodium bisulfite after 3min, adds 1.3g of ammonium persulfate after 3min, React at a temperature of 40°C for 2 to 8 hours. During the reaction, detect the molecular weight of the product. When the molecular weight is 5517, add 2.5 g of sodium formate. After the reaction is complete, a clay stabilizer is obtained. Its structural formula is as follows after infrared analysis:

[0044]

[0045] In the formula, x:y:z=25:9:10.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com