A method for extracting and purifying chlorogenic acid from Jerusalem artichoke leaves

A technology of chlorogenic acid and Jerusalem artichoke, which is applied in chemical instruments and methods, preparation of organic compounds, separation/purification of carboxylic acid esters, etc., can solve the problems of unsecured safety, destruction of ecological environment, limited raw materials, etc. Achieve the effect of shortening post-processing time, less control parameters, and fast adsorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

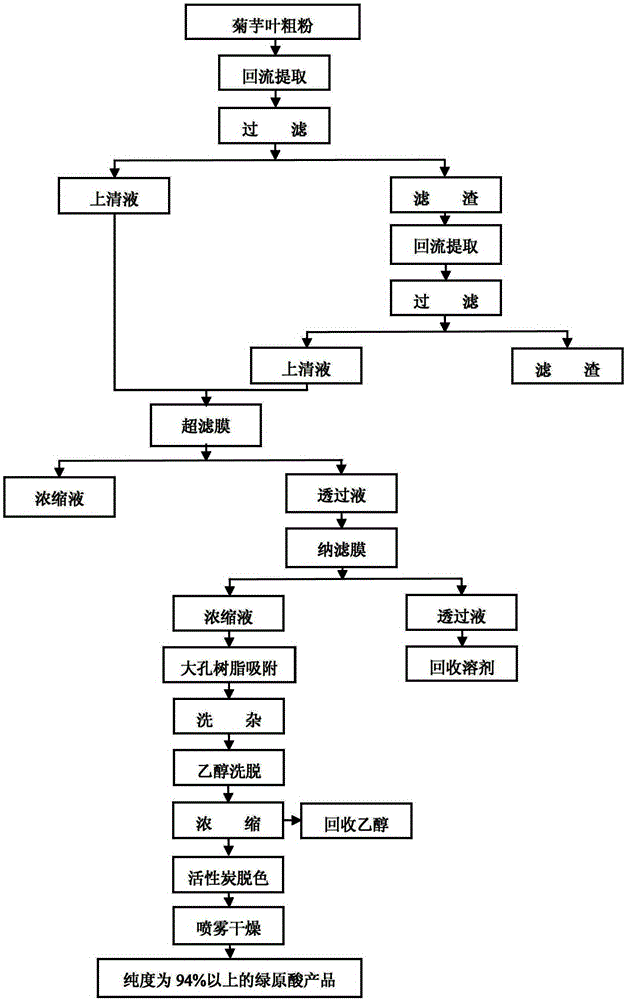

Method used

Image

Examples

Embodiment 1

[0032] Accurately weigh the above 100g of Jerusalem artichoke leaf coarse powder into the extractor, add 500mL of methanol aqueous solution with a volume fraction of 10%, and heat and reflux at 100°C for extraction twice, each time for 1h. Filter and combine the extracts. The extract is first passed through a hollow fiber ultrafiltration membrane with a molecular weight cut off of 1000 to remove macromolecular impurities, and then the extract is concentrated to 10% of the original volume fraction with a nanofiltration membrane with a molecular weight cut off of 200. The concentrated solution is put on the ADS-7 macroporous resin column at a flow rate of 5BV / h. After the dynamic adsorption is saturated, the macroporous resin column is rinsed with an aqueous hydrochloric acid solution with pH=5-6 at a flow rate of 5BV / h until the effluent is colorless. , and then elute with 40% ethanol at a flow rate of 5BV / h, collect the ethanol eluate, concentrate it under reduced pressure to ...

Embodiment 2

[0034] Accurately weigh 500g of Jerusalem artichoke leaf meal and put it into an extractor, add 3000mL of 30% ethanol aqueous solution, heat and reflux at 80°C to extract twice, each time for 2.5h. Filter and combine the extracts. The extract is first passed through a hollow fiber ultrafiltration membrane with a molecular weight cut off of 1000 to remove macromolecular impurities, and then the extract is concentrated to 10% of the original volume fraction with a nanofiltration membrane with a molecular weight cut off of 200. The concentrated solution is put on the DM130 macroporous resin column at a flow rate of 4BV / h. After the dynamic adsorption is saturated, the macroporous resin column is rinsed with a hydrochloric acid aqueous solution with pH=5-6 at a flow rate of 4BV / h until the effluent is colorless, and then Use ethanol with a volume fraction of 60% to elute at a flow rate of 6BV / h, collect the ethanol eluent, concentrate it under reduced pressure to a paste, and then...

Embodiment 3

[0036] Accurately weigh 1000g of Jerusalem artichoke leaf coarse powder and put it into an extractor, add 8000mL of 60% ethanol aqueous solution, heat and reflux at 50°C to extract twice, each time for 3h. Filter and combine the extracts. The extract is first passed through a hollow fiber ultrafiltration membrane with a molecular weight cut off of 1000 to remove macromolecular impurities, and then the extract is concentrated to 10% of the original volume fraction with a nanofiltration membrane with a molecular weight cut off of 200. The concentrated solution is applied to the HPD-600 macroporous resin column at a flow rate of 3BV / h. After the dynamic adsorption is saturated, the macroporous resin column is rinsed with an aqueous hydrochloric acid solution with pH=5-6 at a flow rate of 3BV / h until the effluent is colorless. , and then eluted with 60% ethanol at a flow rate of 8BV / h, collected the ethanol eluate, concentrated it under reduced pressure to a paste, and then dissol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com