Target assembly and manufacturing method thereof

A manufacturing method and target technology, which are applied in manufacturing tools, metal material coating process, ion implantation plating, etc., can solve problems such as unfavorable operations and difficult discharge, and achieve the goal of reducing welding defects and improving welding bonding rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] As described in the background technology, in the existing manufacturing method of target components, during the process of welding the target and the back plate, there is likely to be gas residue between the target and the back plate, and these residual gases are likely to cause the target , The reduction of the bonding rate of the back plate welding.

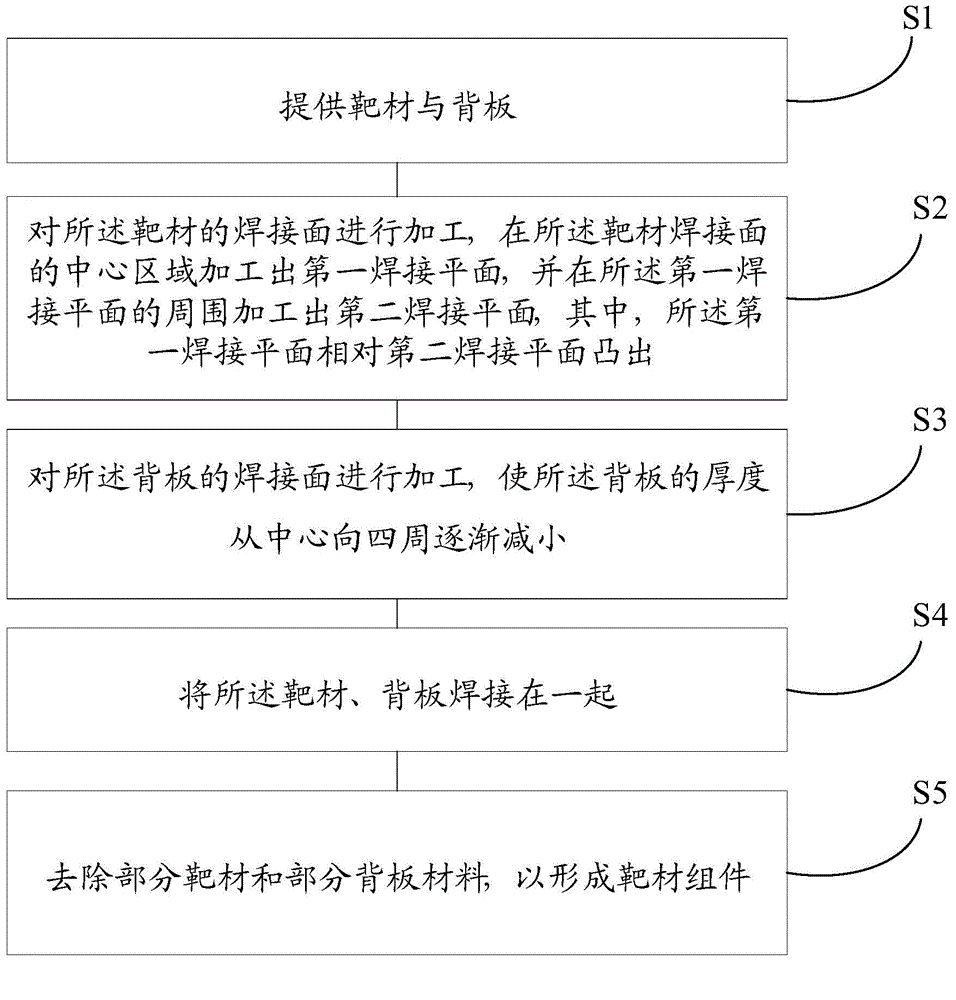

[0037] In order to solve the technical problem, the present invention provides a method for manufacturing a target assembly. refer to image 3 , shows a schematic flow chart of an embodiment of the manufacturing method of the target assembly of the present invention. The manufacturing method generally includes the following steps:

[0038] Step S1, providing a target and a back plate;

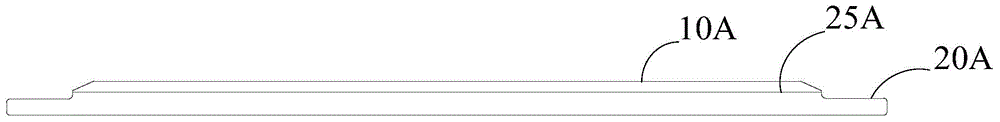

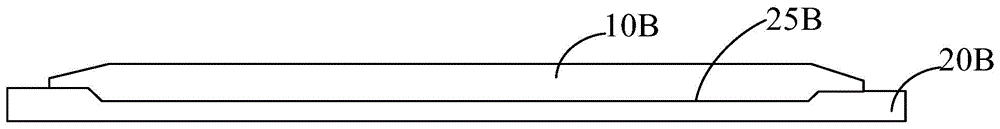

[0039] Step S2, processing the welding surface of the target, machining a first welding plane in the central area of the target welding surface, and machining a second welding plane around the first welding plane, wherein, The firs...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com