Electric pump

A technology for electric pumps and pump bodies, which is applied in the direction of pumps, pump devices, electromechanical devices, etc. It can solve the problems of large volume, heavy weight, and many materials used in electric pumps, and achieve small volume, light weight, and overall volume. The effect of shrinking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

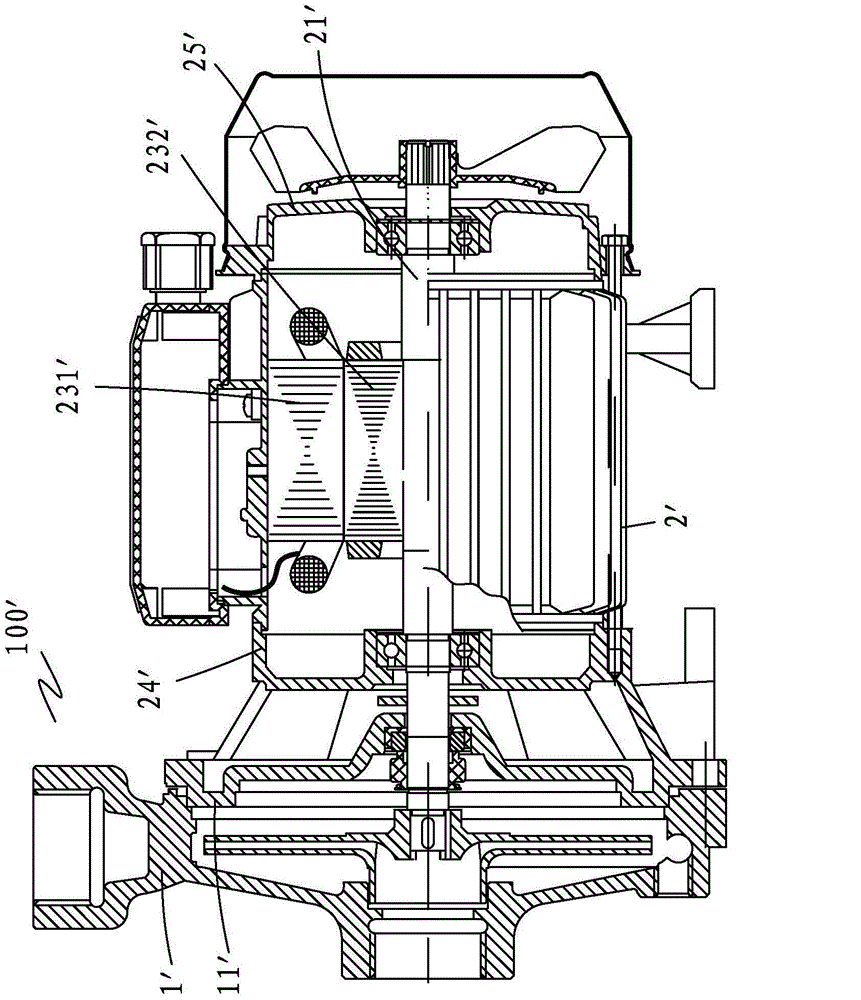

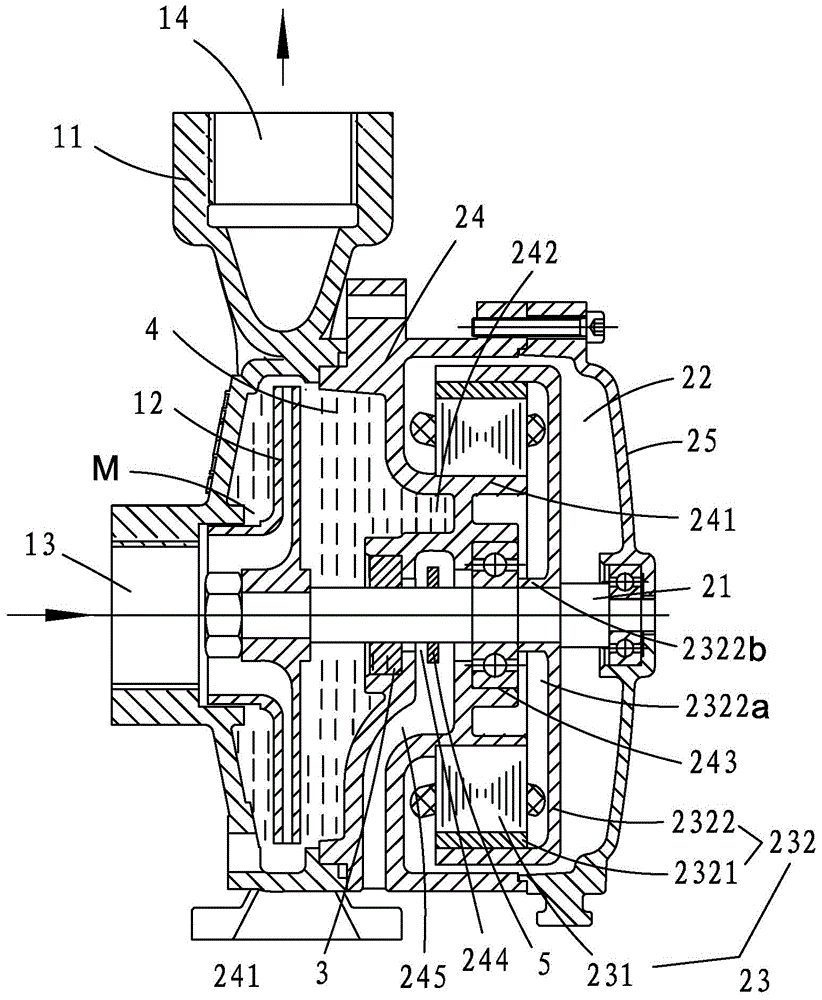

[0024] see image 3 , an electric pump 100, including a pump body 1 and a motor 2; the motor 2 includes a rotating shaft 21, a motor inner cavity 22, a motor unit 23 accommodated in the motor inner cavity 22, a front end cover 24 and a rear end cover 25; The motor inner cavity 22 is surrounded by a front end cover 24 and a rear end cover 25, and the rear end cover 25 is locked and connected with the front end cover 24; the middle part of the front end cover 24 bulges toward the motor inner cavity 22, forming A convex ring 241.

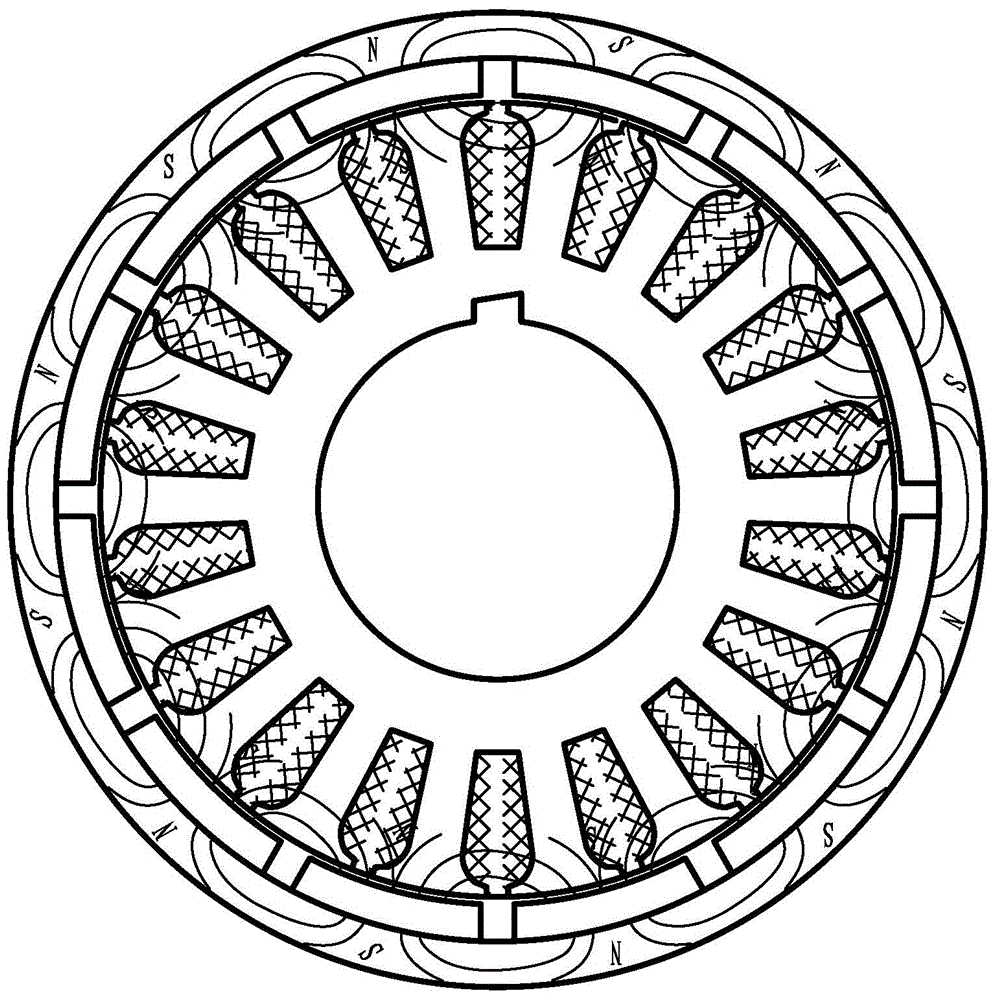

[0025] see again image 3 , the motor unit 23 includes an inner stator 231 and an outer rotor 232 , and the inner stator 231 is tightly sleeved on the protruding ring 241 . The outer rotor 232 includes a magnetic steel 2321 and a bracket 2322, the bracket 2322 is a cylinder 2322a with a central hole, and the central hole of the cylinder 2322a protrudes upwards to form a collar 2322b; the cylinder 2322a covers Set on the inner stator 231, the magneti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com