Gallium-nitride-based power heterojunction field effect transistor with local back barrier

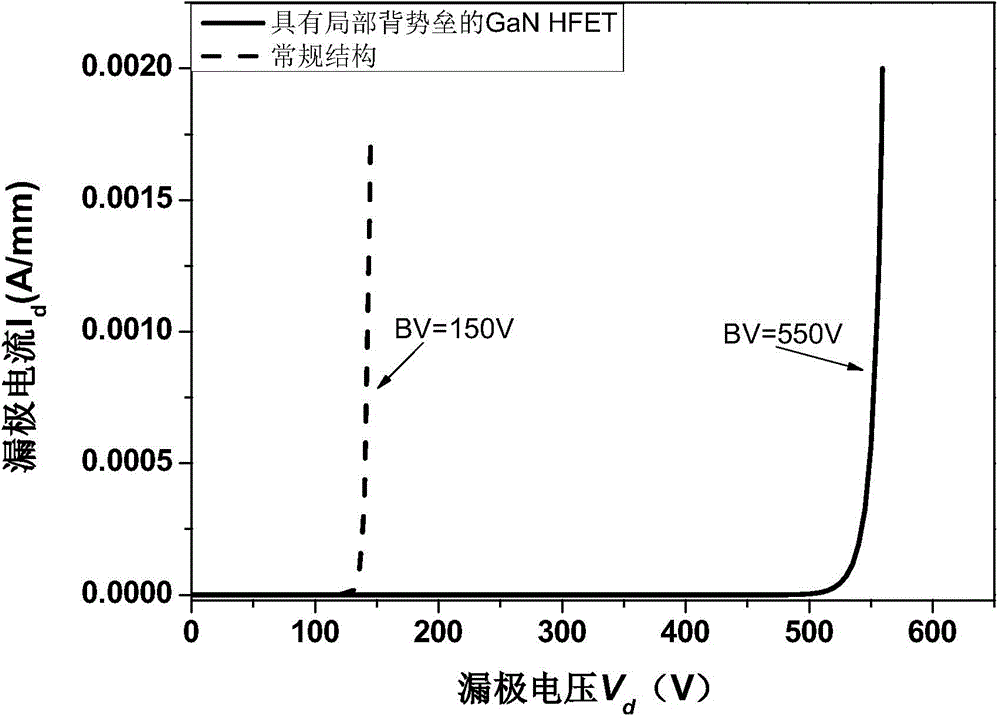

A heterojunction field effect and back barrier technology, applied in semiconductor devices, electrical components, circuits, etc., can solve problems such as increased on-resistance, current collapse effect, and output current drop, to improve withstand voltage, Improve reliability and realize simple effect of device process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

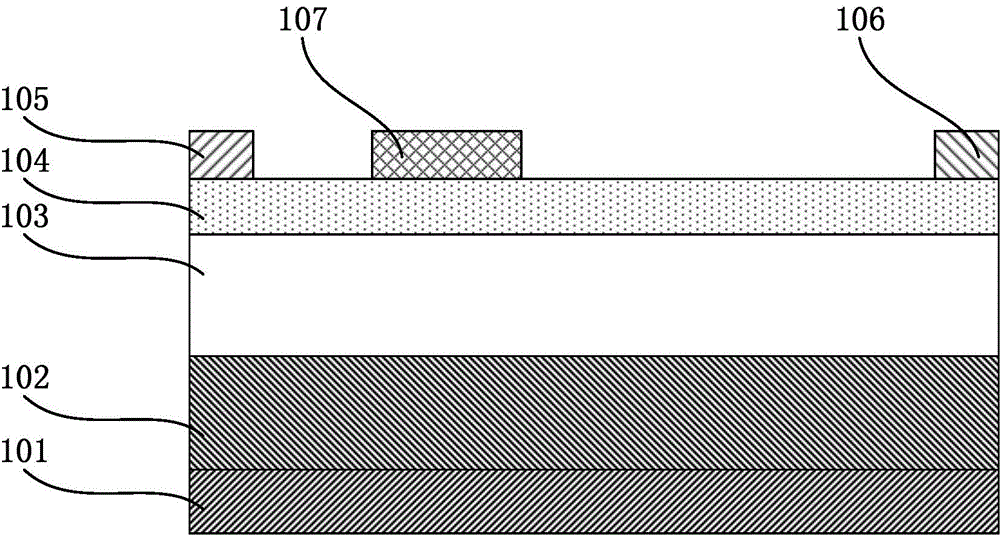

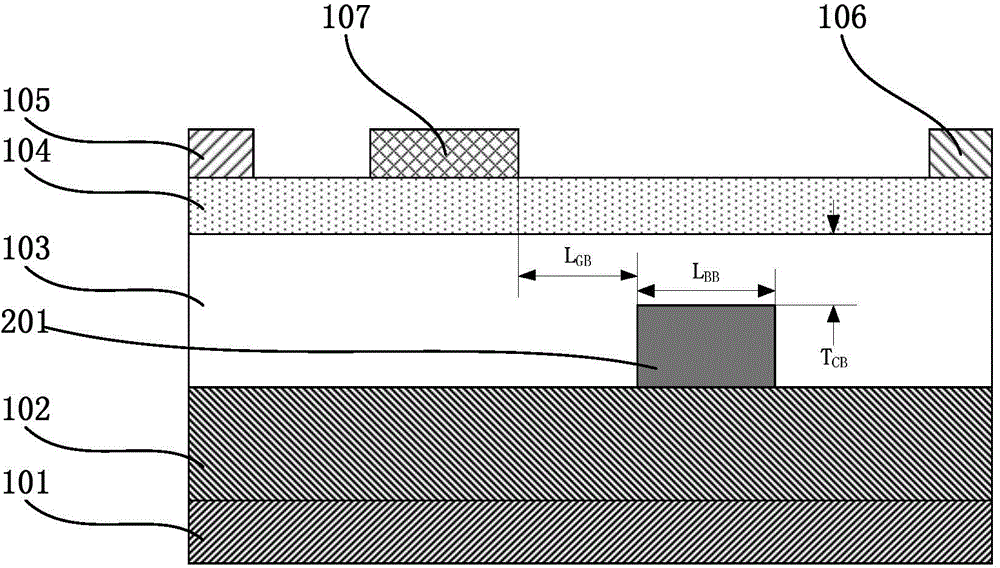

[0026] The GaN HFET structure provided by this embodiment with a local back barrier layer is as follows figure 2 As shown, the main process steps are as follows: sequentially grow an aluminum nitride (AlN) nucleation buffer layer 102 on the substrate by MOCVD, and grow between the gate and drain of the aluminum nitride (AlN) nucleation buffer layer 102 by selective epitaxy Aluminum Indium Gallium Nitride (AlInGaN x In y Ga z N) local back barrier layer 201; then other regions above the nucleation buffer layer 102 start to grow gallium nitride (GaN) channel layer 103, and grow aluminum indium gallium nitride (AlGaN) on the channel layer 103 x In y Ga z N) Barrier layer 104; a source 105 and a drain 106 in ohmic contact with the barrier layer 104 and a gate 107 in Schottky contact are formed on the barrier layer 104.

[0027] The aluminum indium gallium nitride (Al x In y Ga z N) The distance between the local back barrier layer 201 and the drain edge of the gate 107 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com