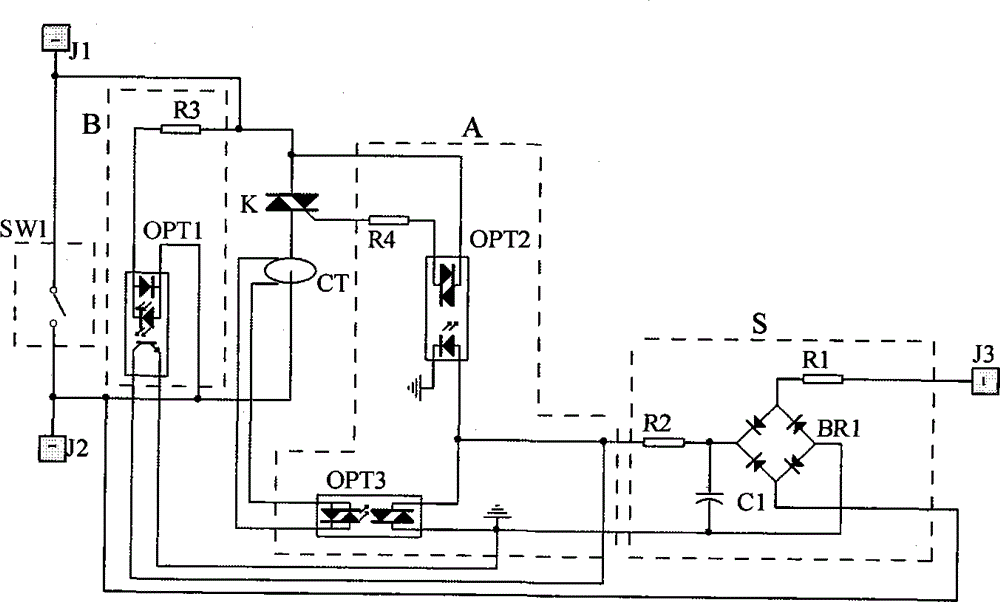

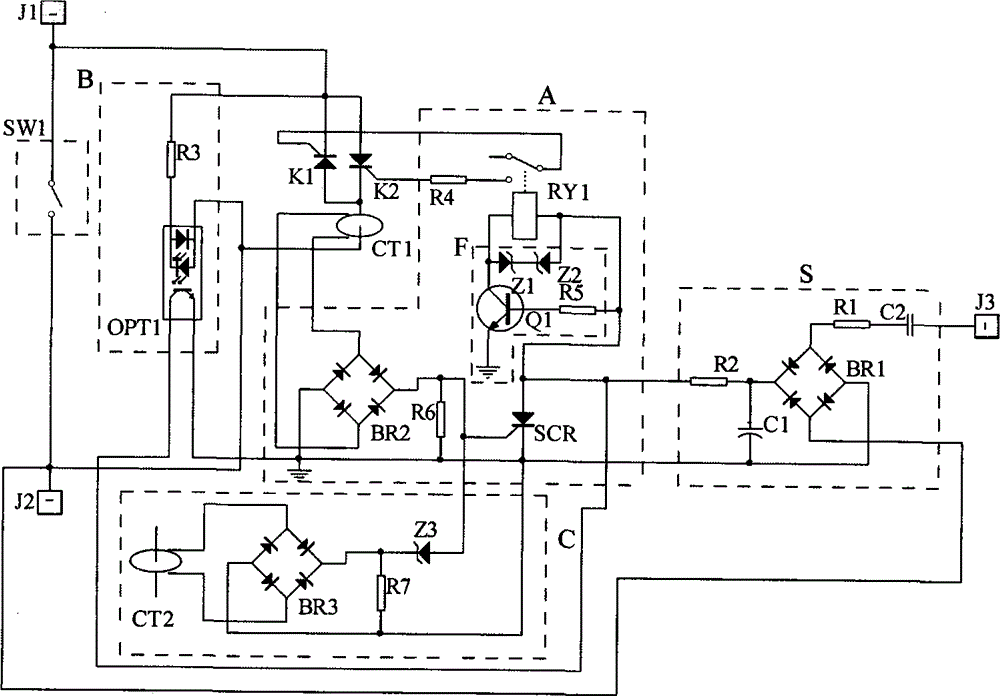

Current feedback electronic arc-control device

An electronic arc extinguishing and current feedback technology, applied in the electrical field, can solve the problems of low reliability, uncertain delay time, long thyristor conduction working time, etc., and achieve a reasonable design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

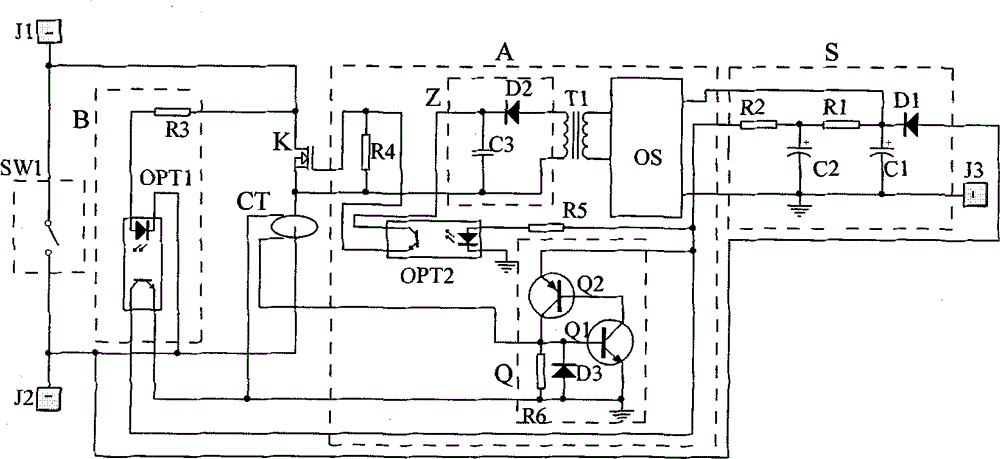

Embodiment 3

[0062] In the third embodiment, the power semiconductor device adopts a field effect transistor, and in practical applications, a fully-controlled semiconductor device such as an IGBT can also be used. When a fully-controlled semiconductor device is used, because of its extremely fast turn-off speed, it can reach the level of microseconds. When controlling inductive loads, anti-parallel diodes can be used as protection in power semiconductor devices, or devices with built-in anti-parallel diodes can be selected. Through the application of the voltage detection circuit (B), not only can the trigger switch (Q) be reset and cut off, but also the output circuit of the power supply circuit (S) can be bypassed and discharged, which greatly improves the secondary performance of the current feedback electronic arc extinguishing device of the present invention. Arc extinguishing response speed.

[0063] Such as Figure 4 Shown is the fourth embodiment of the current feedback type elec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com