Openable Rogowski coil assembly for measuring lightning current in power transmission line

A Rogowski coil and transmission line technology, applied in the field of openable Rogowski coils, can solve the problems of accurate measurement of parameters affecting lightning current, changes in the shape and structure of the winding coil, and the Rogowski coil has no hard shell protection and plasticity, so as to ensure measurement accuracy. and service life, improve mechanical strength and stability, and overcome the inconvenience of on-site installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

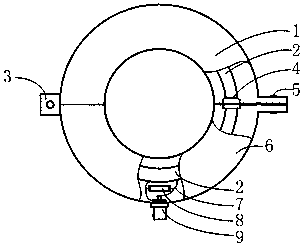

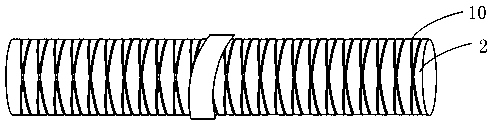

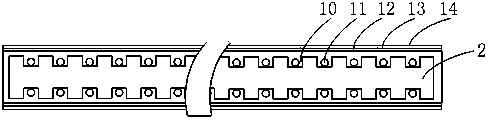

[0028] figure 1 It is a schematic diagram of the overall structure of the present invention, the left end of the semicircular upper coil housing 1 and the left end of the lower coil housing 6 are hinged together through the hinge 3, and the right end of the upper coil housing 1 and the right end of the lower coil housing 6 are screwed together. The nuts 5 are connected to form a circle; the inner wall of the upper coil shell 1 and the inner wall of the lower coil shell 6 are fixed with a semicircular flexible Rogowski coil thread skeleton 2, which is processed on the side wall of the flexible Rogowski coil thread skeleton 2 There is a threaded groove 10, and the winding coil 11 is evenly wound in the threaded groove 10 on the flexible Rogowski coil threaded skeleton 2, and the outer layer of the flexible Rogowski coil threaded skeleton 2 and the wound coil 11 is covered with an insulating sleeve 12, The inner shielding layer 13 is wrapped on the outer layer of the insulating s...

Embodiment 2

[0039] The structure of embodiment 2 is basically the same as embodiment 1, the difference is:

[0040] The threaded groove 10 on the flexible Rogowski coil threaded skeleton 2 is a unidirectional threaded groove, and the groove spacing between two unidirectional threaded grooves is twice the diameter of the unidirectional threaded groove.

[0041] The groove pitch of the unidirectional thread groove is equidistant.

Embodiment 3

[0043] In this embodiment, the value of the integral resistor 8 is relatively large, 510Ω, forming an external integral Rogowski coil. The integral resistor 8 and the integral circuit composed of an operational amplifier jointly restore the differential signal induced by the Rogowski coil, so that the output signal It is proportional to the measured current.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com