In-situ structure analytical method for nodular cast iron metal material before and after impact fracture

An impact fracture, ductile iron technology, applied in the field of metallography, can solve the problem of no in-situ impact test device and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Take QT400-18L ferritic ductile iron as an example:

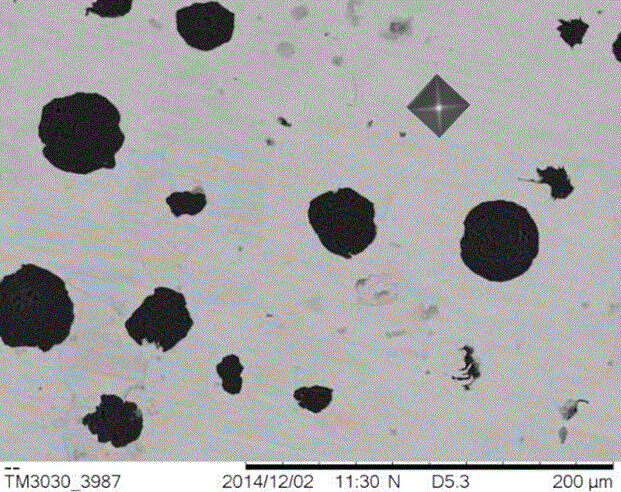

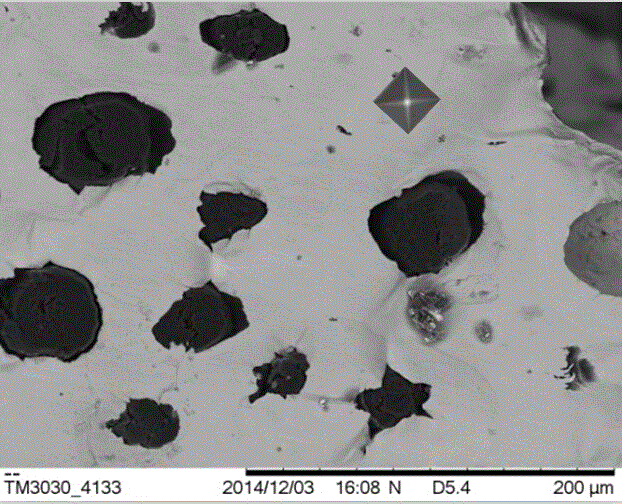

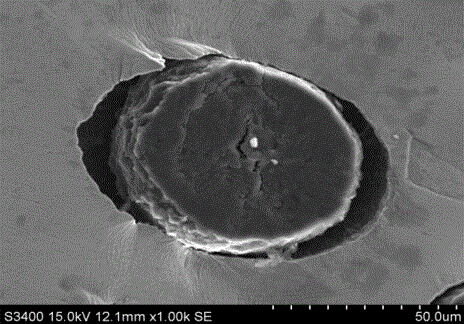

[0014] The QT400-18L nodular cast iron was used to prepare V-shaped notch impact samples according to the conventional method, and the two sides of the sample containing the V-shaped notches were roughly ground and finely ground, and polished with abrasive paste and corroded by 4% nitric acid alcohol. Observe the sample and select the target microstructure area near the V-shaped notch. An indentation mark was made on the target area using a Vickers microhardness tester with a load of 0.2 kgf. The target area was photographed using a scanning electron microscope. Put the photographed sample into a low-temperature tank, lower it to the required test temperature (take -20°C as an example) with liquid nitrogen, and keep it warm for 15 to 20 minutes, then quickly take out the sample, and place it under the pendulum impact testing machine. A Charpy notched impact test was performed. The fractured impact sample was obser...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com