Waste water and heat utilization device for mushroom culture medium sterilization boiler

The technology of culture medium sterilization and sterilization furnace is applied in the field of mushroom culture medium sterilization boiler wastewater and waste heat utilization device, and can solve the problems of high cost and waste of heat energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

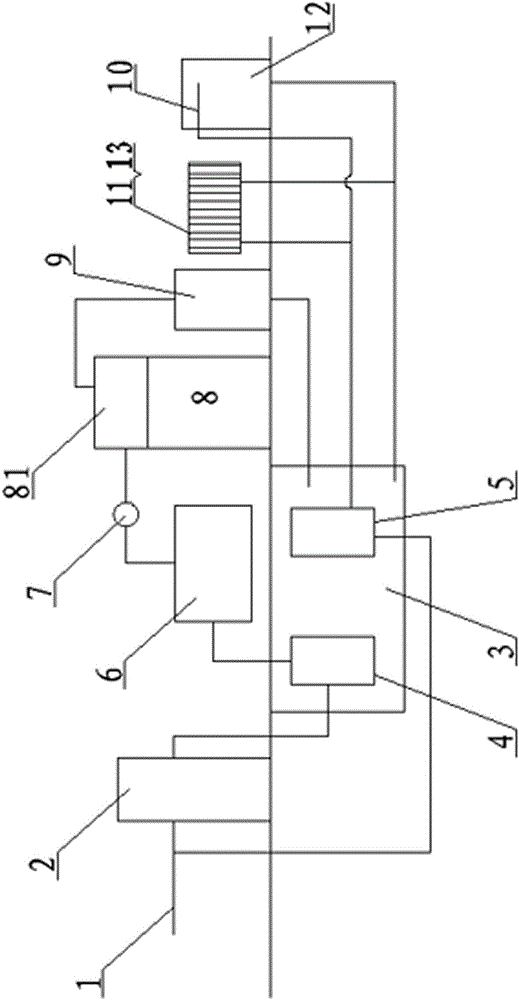

[0014] Further description will be made below in conjunction with the accompanying drawings.

[0015] figure 1 As shown, a mushroom culture medium sterilizing boiler waste water and waste heat utilization device includes a tap water inlet pipe 1, a fully automatic water processor 2, a waste water pool 3, a first heat exchanger 4, a second heat exchanger 5, and a softened water tank 6. Water pump 7, boiler 8, sterilizing furnace 9, water supply pipe 10 and heating pipe 11, tap water inlet pipe 1 is divided into two routes, one route is connected to the first heat exchanger 4 through the automatic water processor 2, and the other route is connected to the second The heat exchanger 5, the first heat exchanger 4 and the second heat exchanger 5 are all arranged in the waste water pool 3, the waste water pool 3 is arranged below the ground, and the two heat exchangers are coil fins; the first heat exchanger 4 The softened water tank 6 and the water pump 7 are connected to the water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com