All-cotton composite functional fabric with all-cotton water-proof, oil-proof and antifouling properties

A technology with antifouling performance and composite function, applied in the field of fabrics and textile fabrics, can solve the problems of single function of fabrics, and achieve the effects of excellent wear resistance, increased softness, and improved bonding fastness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

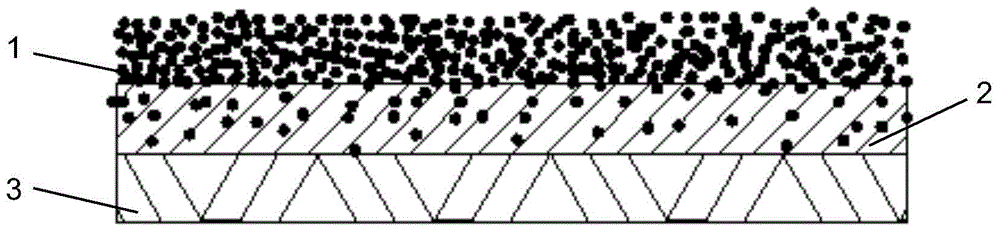

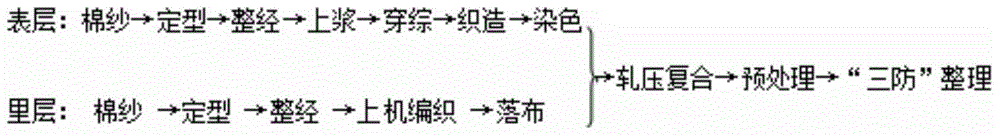

[0035] Woven fabric layer: Plain weave is used, the yarn raw materials used are all cotton yarns, the warp and weft yarns are 15.6tex, the warp density is 620 threads / 10cm, and the weft density is 336 threads / 10cm.

[0036] Knit layer:

[0037] The rib weave is used, and the yarn raw materials used are all cotton yarns. The yarn number used is 5.9tex, the horizontal density is 164 rows / 10cm, the vertical density is 150 rows / 10cm, and the needle size is 36 or 40G. , woven on a large circular knitting machine.

[0038] Preprocessing:

[0039] Using acid cellulase treatment, combined with low temperature plasma treatment process.

[0040] "Three-defense" finishing agent:

[0041] Including nano fluoride finishing agent and ceramic powder nanoparticles.

[0042] Finally, the "three-proof" performance test and the washability test (washed 5 times) were carried out on the cotton three-proof (waterproof, oil-proof, anti-fouling) composite functional fabric. The test results show...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com